Hollow two-layer light-load belt line

A double-layer, light-load technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as increasing belt lines, increasing costs, and inability to achieve continuous transportation, reducing friction and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

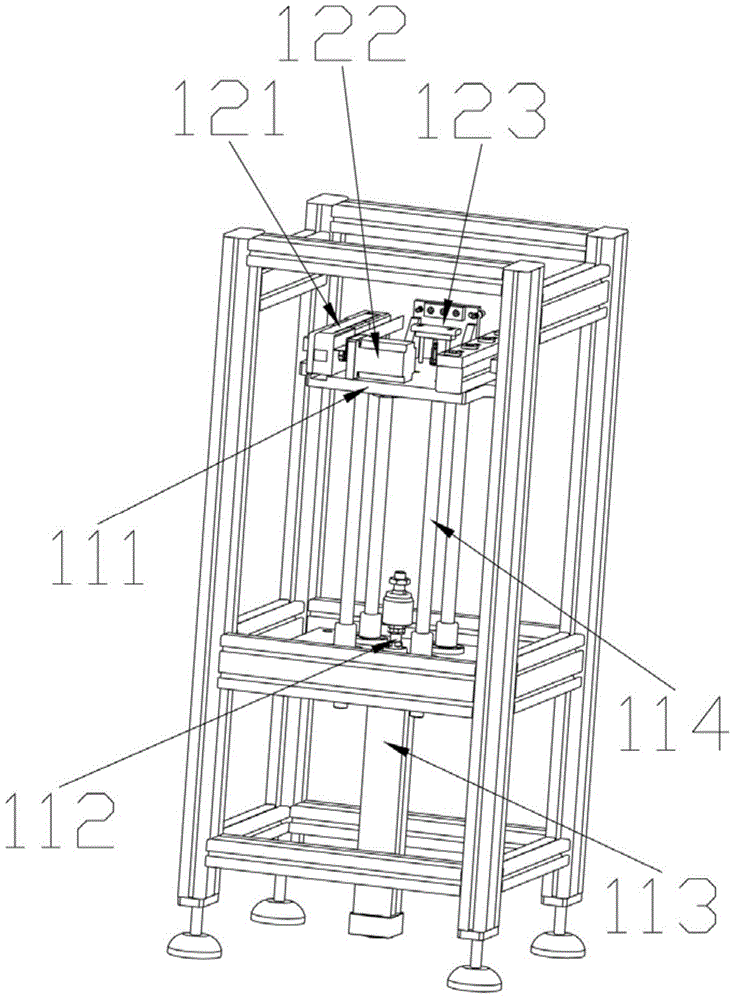

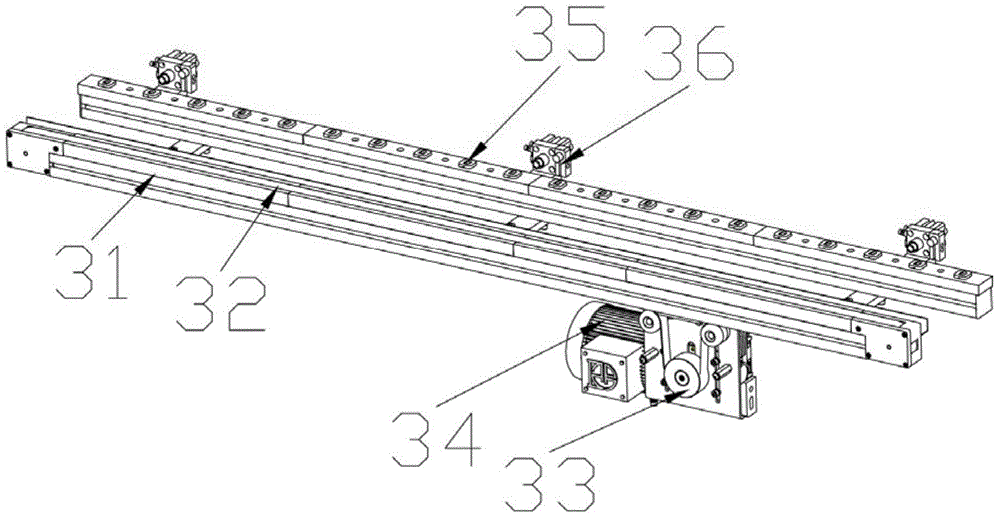

[0022] figure 1 It is a structural schematic diagram of a double-layer light-load belt line of the present invention; it includes a left lifting mechanism 1 and a right lifting mechanism 2 with the same structure for lifting and lowering pallets loaded with materials, and the left lifting mechanism and the right lifting mechanism are connected There are an upper conveyor belt mechanism 3 and a lower conveyor belt mechanism 4 for transporting materials. The structure of the upper conveyor belt mechanism and the lower conveyor belt mechanism is the same. A jacking assembly 11, the top of which is provided with a transporting assembly 12 for transporting the pallet to the upper conveyor belt mechanism or the lower conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com