Auxiliary propulsion energy-saving device for ship hydrodynamics

An energy-saving device and auxiliary propulsion technology, applied in the direction of rotary propellers, rotary propellers, etc., can solve problems such as weakening of the effect, achieve the effect of reducing the power of the main engine and improving the propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

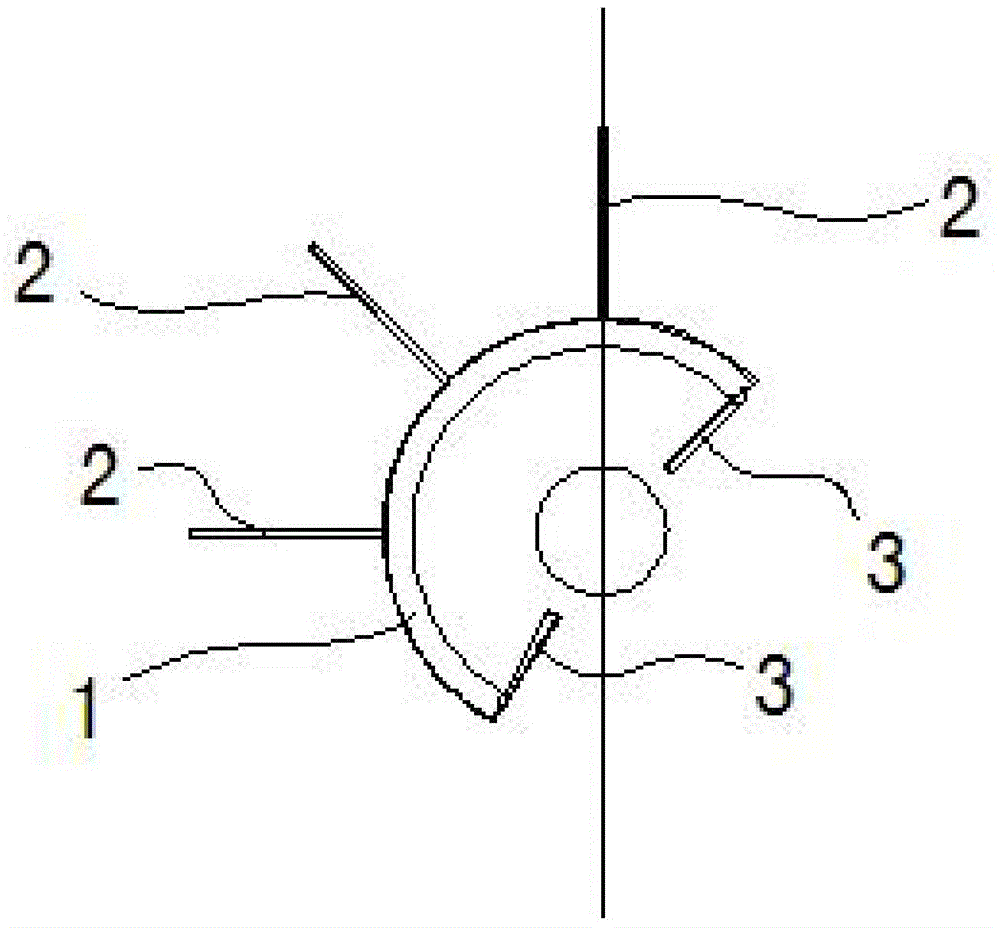

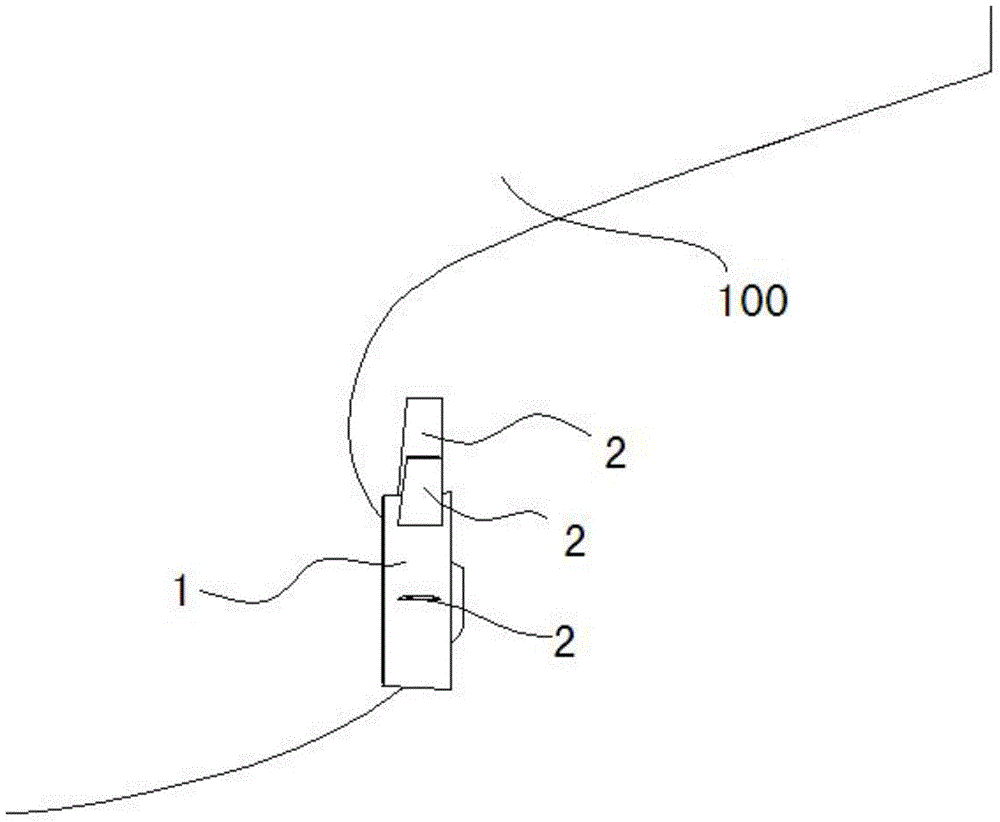

[0025] Such as figure 1 and figure 2 As shown, one end of the second hydrofoil 2 is fixed on the outside of the first hydrofoil 1, and the other end is centered on the axis of the propeller and radially distributed outward. The sectional view of the second hydrofoil is specifically as follows Figure 4 As shown (plane a is the back of the wing, and plane b is the airfoil); the farthest distance between the second hydrofoil 2 and the propeller axis is equal to the radius of the propeller.

[0026] In a preferred embodiment of the present invention, one end of the second hydrofoil 2 is fixed on the outside of the first hydrofoil 1, and the other end is centered on the axis of the propeller, radially distributed outward, and the distance between the second hydrofoil 2 and the axis of the propeller is the farthest It is equal to the propeller radius, and the number is 2 to 4 pieces. Its main function is to change the flow direction within the large radius range of the propeller,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com