Gripper

A technology of grippers and workpieces, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as workpiece deformation, inability to adjust the assembly process in a timely manner, and force conditions that cannot be monitored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

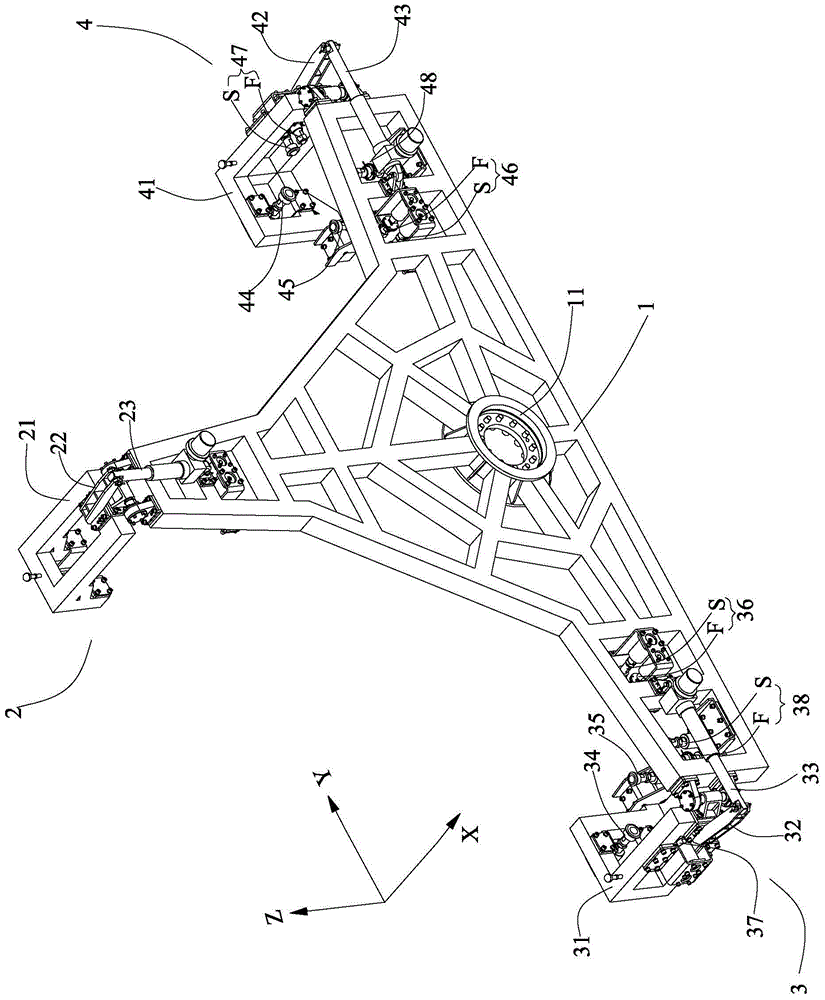

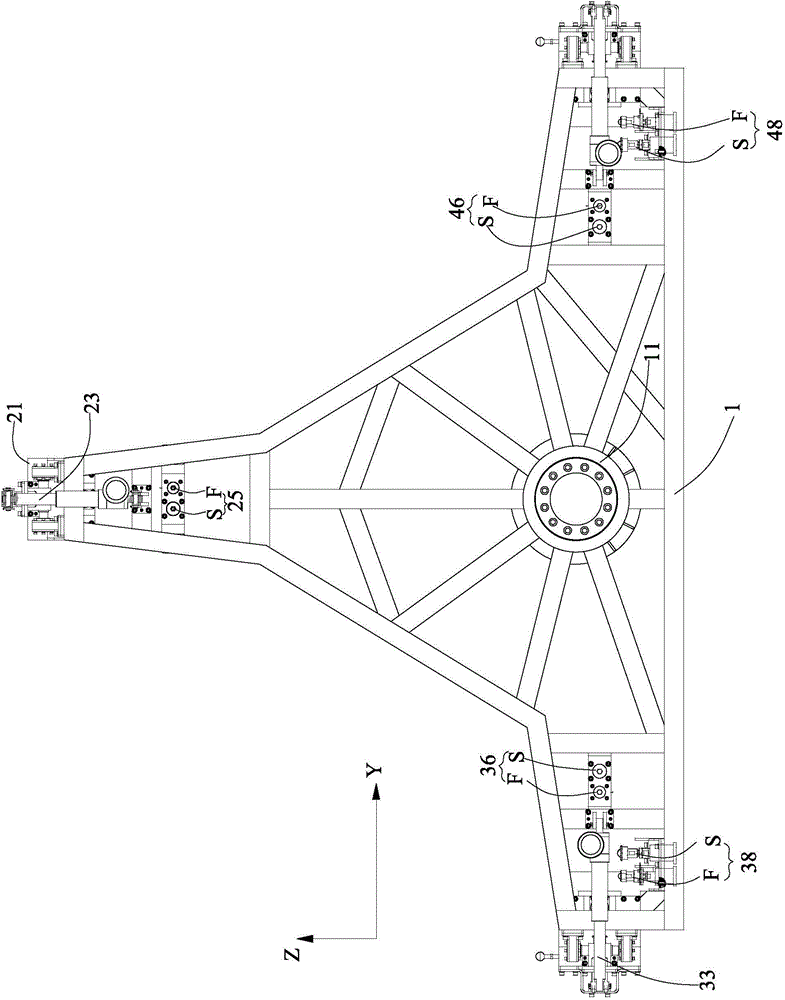

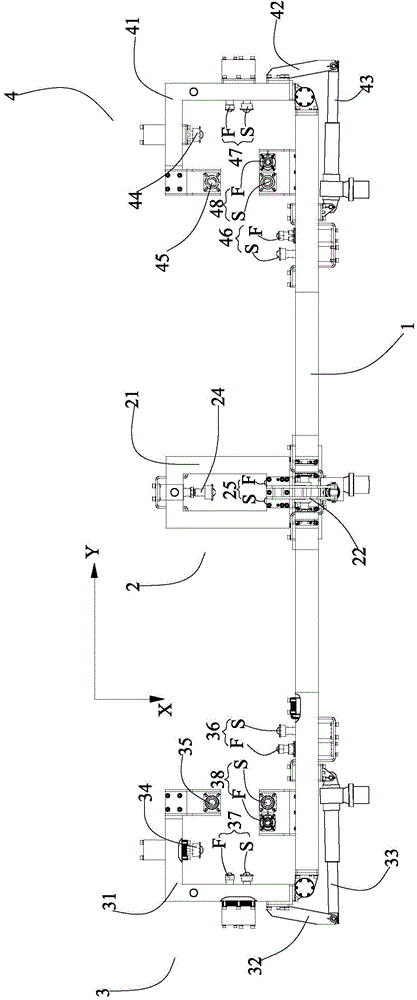

[0045] The gripper according to the present invention will be described in detail below with reference to the accompanying drawings.

[0046] refer to Figure 1 to Figure 5 , The gripper according to the present invention includes a body 1 , an upper gripper assembly 2 , a left gripper assembly 3 and a right gripper assembly 4 .

[0047] The upper gripper assembly 2 includes: an upper main body 21, which is pivotally connected to the upper end of the body 1; an upper pivotal connecting arm 22, one end of which is fixedly connected to the upper telescopic link 23 of the upper main body 21, and one end which is pivotally connected to The other end of the upper pivotal connecting arm 22 is fixedly connected to the body 1 and can be stretched; the upper X-direction support spring body 24 is arranged on the upper body 21 and can be elastically stretched for elastic contact and clamping in the X direction Or loosen the workpiece; the upper side X-direction force-measuring support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com