Centerless grinding machine

A centerless grinding machine and protective sleeve technology, which can be used in grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc. Achieve the effect of avoiding grinding dead corners, good grinding effect and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

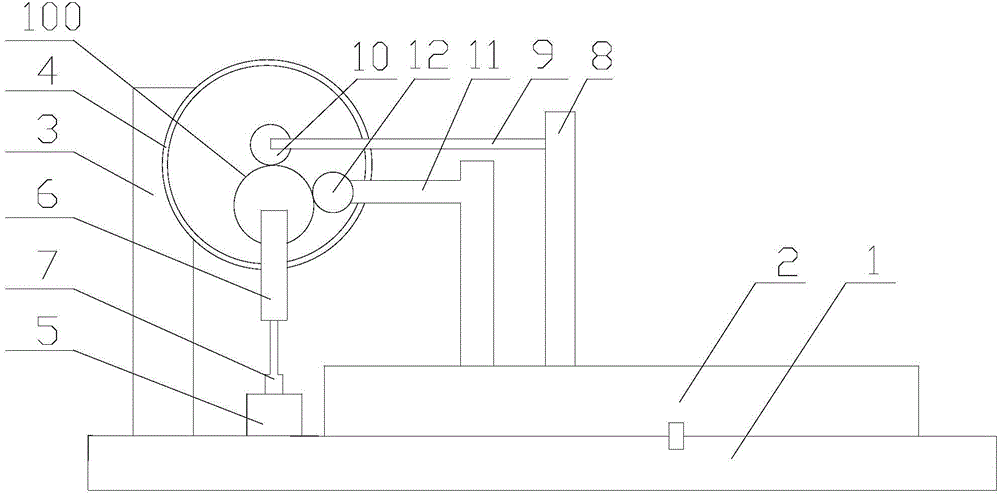

[0014] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a centerless grinding machine proposed by the present invention.

[0015] refer to figure 1 , the present invention proposes a centerless grinding machine, including: a base 1, a workbench 2, a mounting seat 3, a protective cover 4, a first holding assembly, a grinding assembly, and a second holding assembly;

[0016] The workbench 2 is horizontally rotatably installed on the base 1 through the rotating shaft, the base 1 is provided with a first guide rail, the mounting seat 3 is installed on the first guide rail of the base 1 through the first slider, and the protective cover 4 is hollow A cylinder, which is arranged on the side of the mounting seat 3 away from the base 1;

[0017] The first clamping assembly includes a first base 5, a first bracket 6, and a telescopic rod 7. The base 2 is provided with a second guide rail, and the first base 5 is installed on the second guide rail of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com