Bending tool

A tool and working platform technology, applied in the field of machinery, can solve the problems of pipe forming angle, length is not easy to control, movement is not flexible, structure is complex, etc., to achieve the effect of flexible length and angle size, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

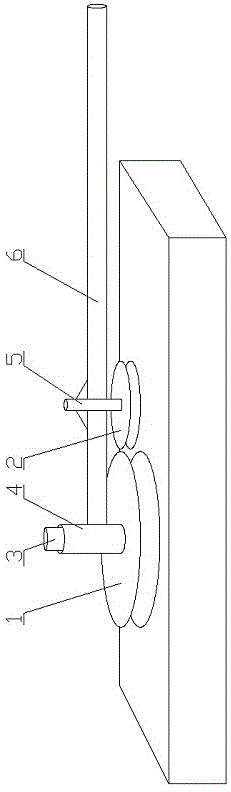

[0012] Such as figure 1 As shown, a bending tool includes a fixed mold 1 fixed on a working platform, a fixed shaft 3 is fixedly installed on the upper part of the fixed mold 1, a removable sleeve 4 is sleeved on the fixed shaft 3, and the sleeve 4 is connected to a handle 6. A movable mold 2 is installed on the handle 6 near the sleeve 4, and a gap is left between the fixed mold 1 and the movable mold 2. The fixed mold 1 and the movable mold 2 are pulley-shaped. Three-quarters of the circumference of the fixed mold 1 extends out of the working platform, and the movable mold 2 is connected to a handle 6 through a small fixed shaft 5, and the handle 6 is a long round tube. The diameter of the fixed mold 1 is larger than the diameter of the movable mold 2.

[0013] When you need to bend a long tube, you only need to extend the long tube between the fixed mold 1 and the movable mold 2, and then turn the handle 6 to drive the movable mold 2 to rotate along the fixed mold 1. The lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com