Detachable hobbing device for roller screen

A technology for dismantling devices and roller sieves, which is applied in the fields of filter screens, solid separation, chemical instruments and methods, etc. It can solve the problems of large assembly errors, time-consuming and labor-intensive replacement process, and affect the service life, so as to save time and effort in the replacement process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

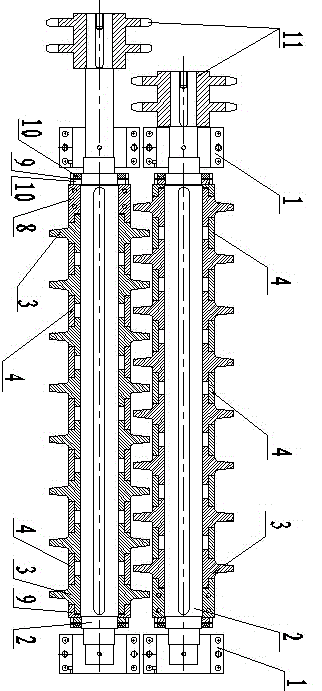

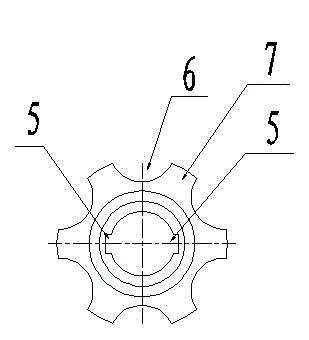

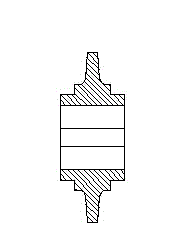

[0017] Such as Figure 1-5 Shown is a specific embodiment of the present invention, the detachable gear hobbing device for the roller screen, including the rollers 2 arranged at both ends of the roller screen support through the bearing housing 1, and the sub-units connected to the rollers 2 in turn. The one-piece hobbing gear 3 also includes a long fixing sleeve 8 and a short fixing sleeve 9 respectively arranged at both ends of the roller shaft 2, and a spacer sleeve 4 arranged between adjacent split-type hobbing gears 3. The stop device for the axial movement of the fixed sleeve, the inner sides of the long and short fixed sleeves are respectively pressed against the outer sides of the ends of the split hob 3, and the inner sides of the two ends of the spacer sleeve 4 are respectively connected to the outer ends of the split hob 3. Press and fit eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com