Novel intelligent coal sorting machine

A sorter, coal technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of low degree of automation, low production efficiency, high labor intensity, etc., to achieve convenient operation, improve work efficiency, and improve intelligence degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

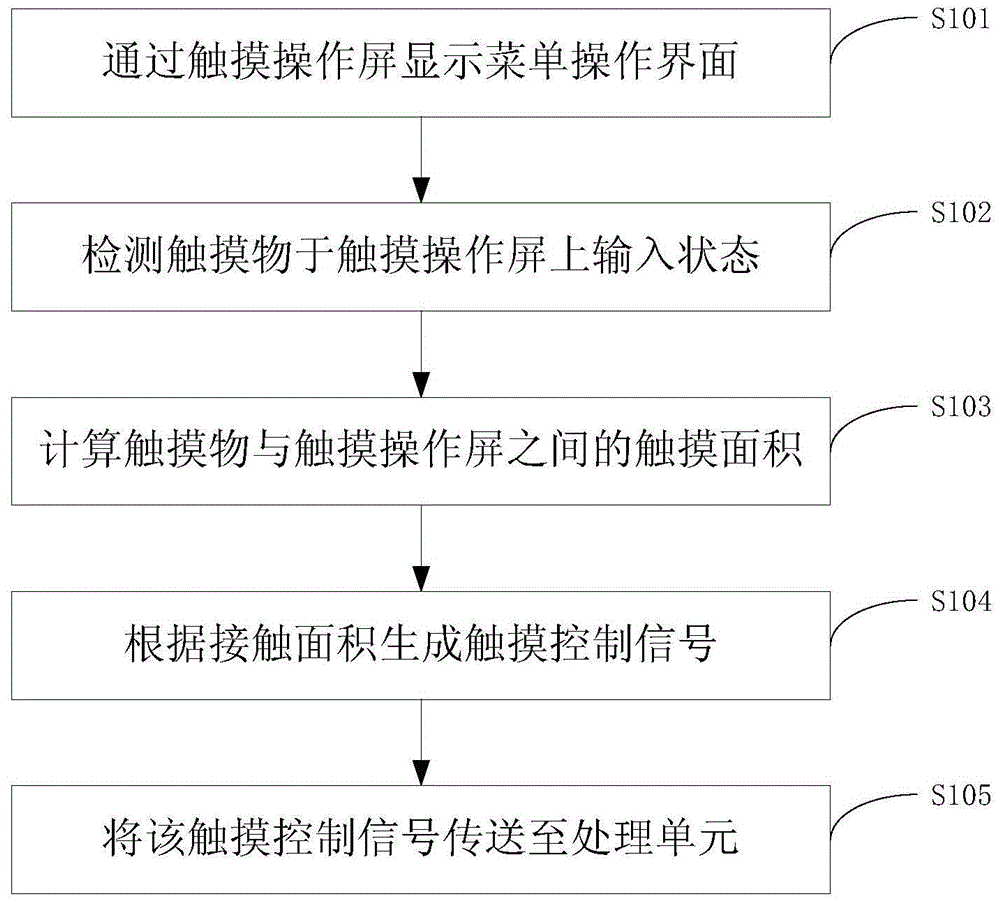

Image

Examples

Embodiment Construction

[0039] In order to further understand the content, features and effects of the present invention, the following examples are cited, and detailed descriptions are made in conjunction with the drawings as follows: The modules or units used in the present invention are all known modules or units. When the software is already installed. There is no software or method innovation in the present invention.

[0040] See Figure 1 to Figure 4 Shown: The new coal intelligent sorting machine includes: feed inlet 1, upper cover 2, screen box 3, fixed plate 4, shock-absorbing spring 5, main body bracket 6, base 7, main control box 8, vibration motor 9, Slag coal passage 10, lump coal passage 11, screen surface 12;

[0041] The upper end of the screen box 3 is equipped with an upper cover 2, and one side of the upper cover 2 is equipped with a feed inlet 1, a fixed plate 4 is installed on both sides of the screen box 3, and a shock-absorbing spring 5 is installed at the lower end of the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com