Waste diatomite processing system and waste diatomite processing technique

A technology of waste diatomite and treatment system, which is applied in the removal of solid waste, animal feed, animal husbandry, etc., can solve the problems of waste diatomite deterioration and odor, difficulty in recycling, environmental pollution, etc., and achieve low moisture content. , The effect of simple structure and high degree of self-control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

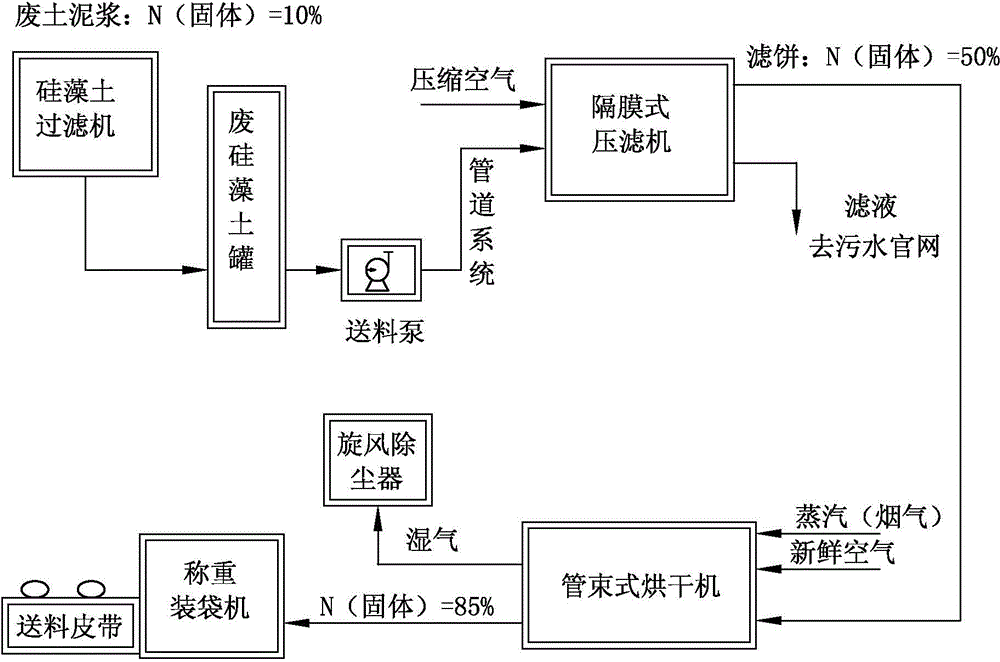

[0033] Such as figure 1 As shown, a waste diatomite treatment system includes a diatomite temporary storage device and dehydration equipment, the diatomite temporary storage device and the dehydration equipment are connected through a pipeline system, and the diatomite temporary storage device and the dehydration equipment are connected. The pipeline system is equipped with a feeding pump; the dehydration equipment is equipped with a material outlet and a liquid outlet, and the liquid outlet is connected to the sewage pipe network.

[0034] The diatomite temporary storage device is a mud pool, and a plurality of air injection pipes are distributed at the bottom of the mud pool, and the air injection pipes are all connected to compressed air pipelines, and the outlet at the bottom of the mud pool is connected to a feeding pump. An air jet pipe is installed at the bottom of the mud pool, and the air jet pipe sprays out compressed air, which can prevent sedimentation.

[0035] T...

Embodiment 2

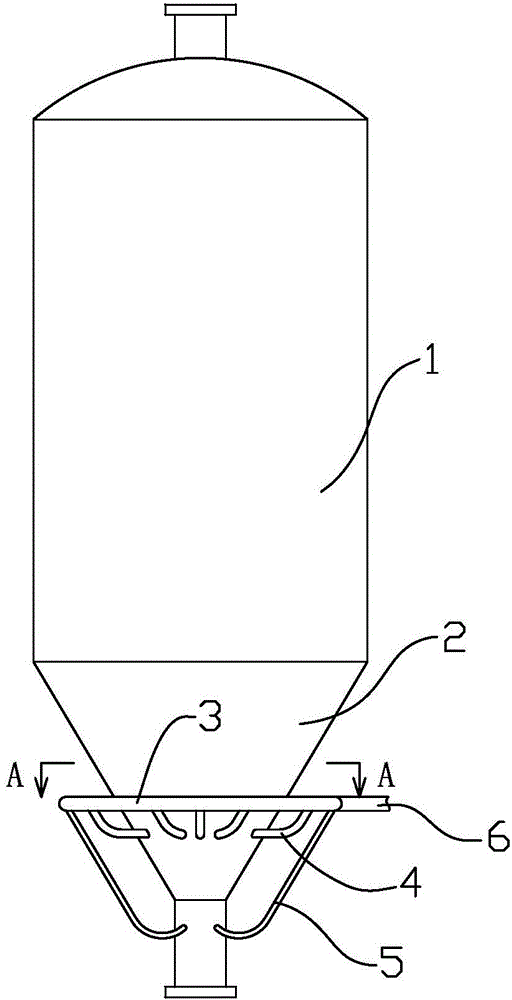

[0046] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the diatomite temporary storage device is a temporary storage tank 1, the feed port of the temporary storage tank 1 is connected to a diatomite filter, and the discharge of the temporary storage tank 1 Connect to the feed pump.

[0047] Such as image 3 , Figure 4 , the bottom of the temporary storage tank 1 is provided with an inverted conical cone 2, in order to avoid clogging, an anti-clogging flushing device is installed on the outside of the cone 2, and the anti-clogging flushing device includes a circular flushing ring pipe 3 , the flushing ring pipe 3 surrounds the outside of the cone part 2 and is connected with the temporary storage tank 1 through the bracket 5, the flushing ring pipe 3 communicates with the water supply pipe 6; the flushing ring pipe 3 is evenly distributed with flushing branch pipes 4, and the flushing branch pipes 4. One end communicates with the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com