Preparation method of fermented soybean meal for feeding

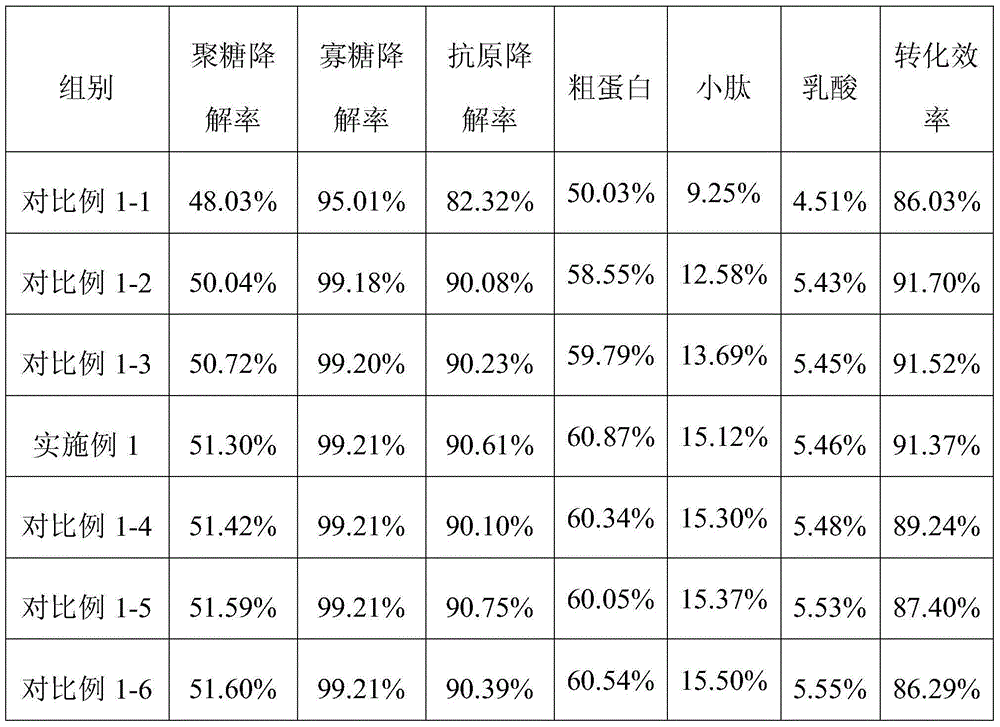

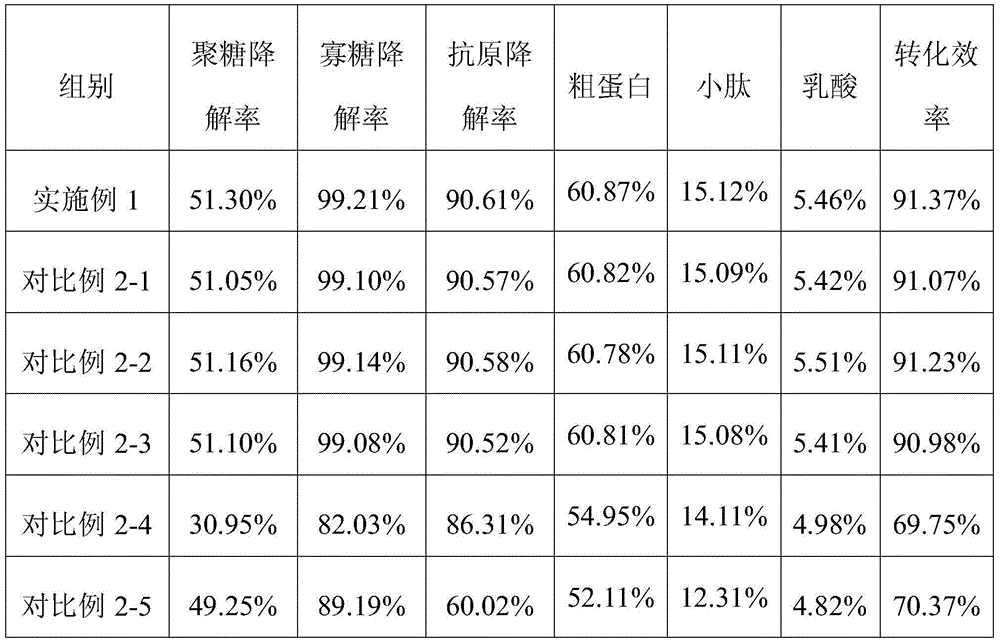

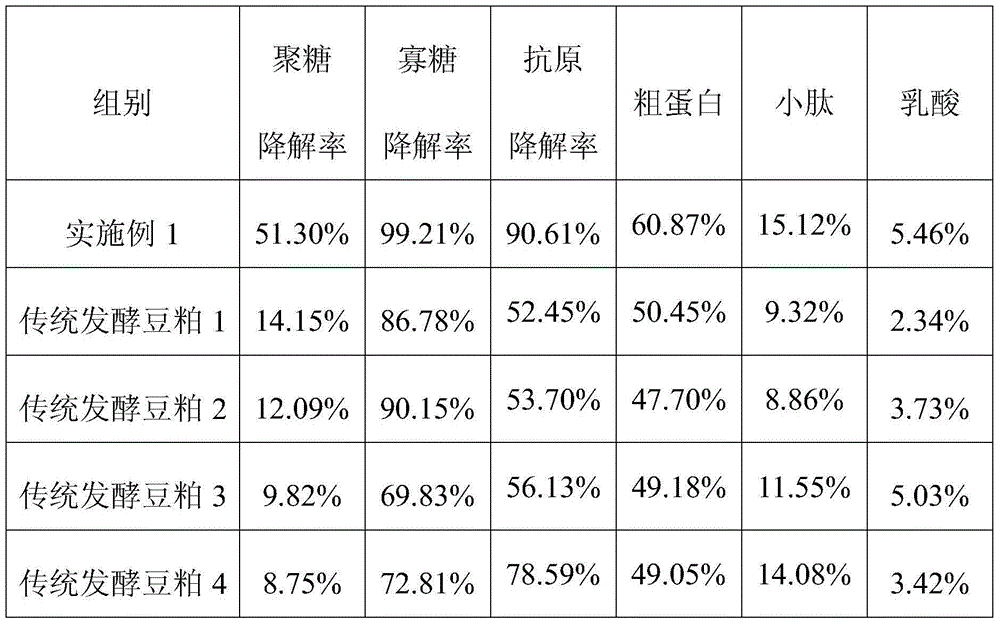

A technology of fermented soybean meal and soybean meal for feeding, applied in the field of fermentation, can solve the problems of difficulty in improving the quality of crude protein, limiting the protein quality of fermented soybean meal, high content of polysaccharides and anti-nutritional factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] (1) Preparation of Aspergillus niger liquid

[0053] A. Inoculate Aspergillus niger into the Aspergillus niger slant culture medium, and cultivate at 25~30°C for 68~76h; pick a ring of Aspergillus niger from the Aspergillus niger slant medium, and inoculate it into the Aspergillus niger liquid medium , cultured at 23-28°C for 72-96 hours to obtain Aspergillus niger enrichment liquid;

[0054] B, get the aspergillus niger enrichment liquid prepared by step A, inoculate the aspergillus niger liquid culture medium with the inoculum size of 0.5~5:100 by volume ratio, adjust the pH to 6.2~6.6, ventilate under 23~28 ℃ ( The air after the filter bacteria treatment) was cultivated for 72-96 hours; after that, each inoculation was inoculated into the Aspergillus niger liquid medium according to the volume ratio of 0.5-5:100, and the pH was adjusted to 6.2-6.6, 23-28 Cultivate for 72-96 hours with aeration (air after filter bacteria treatment) at ℃, until it expands to 5L. At th...

Embodiment 1

[0083] (1) Preparation of Aspergillus niger liquid

[0084] A. Inoculate Aspergillus niger into Aspergillus niger slant culture medium, and cultivate for 72h at 28°C; pick a ring of Aspergillus niger from Aspergillus niger slant culture medium, inoculate it into Aspergillus niger liquid culture medium, 23~28 Cultivate at ℃ for 72-96 hours to obtain Aspergillus niger enrichment liquid;

[0085] B. Take the Aspergillus niger enrichment liquid prepared in step A, inoculate it into the Aspergillus niger liquid culture medium with an inoculum size of 0.5~5:100 by volume ratio, adjust the pH to 6.2~6.6, and cultivate under ventilation at 23~28°C 72-96 hours; after that, each inoculation should be inoculated into the Aspergillus niger liquid culture medium according to the volume ratio of 0.5-5:100, adjust the pH to 6.2-6.6, and incubate at 23-28°C for 72-96 hours until Expand to 5L, at this time, the number of live bacteria of Aspergillus niger in Aspergillus niger liquid medium is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com