Cleaning system for sand filtration layer

A technology for cleaning the system and filtering the sand layer, which is applied in the field of cleaning systems, can solve the problems of enlarged project scale and high operating cost, and achieve the effects of miniaturization of equipment, prevention of mesh clogging, and reduction of project scale and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

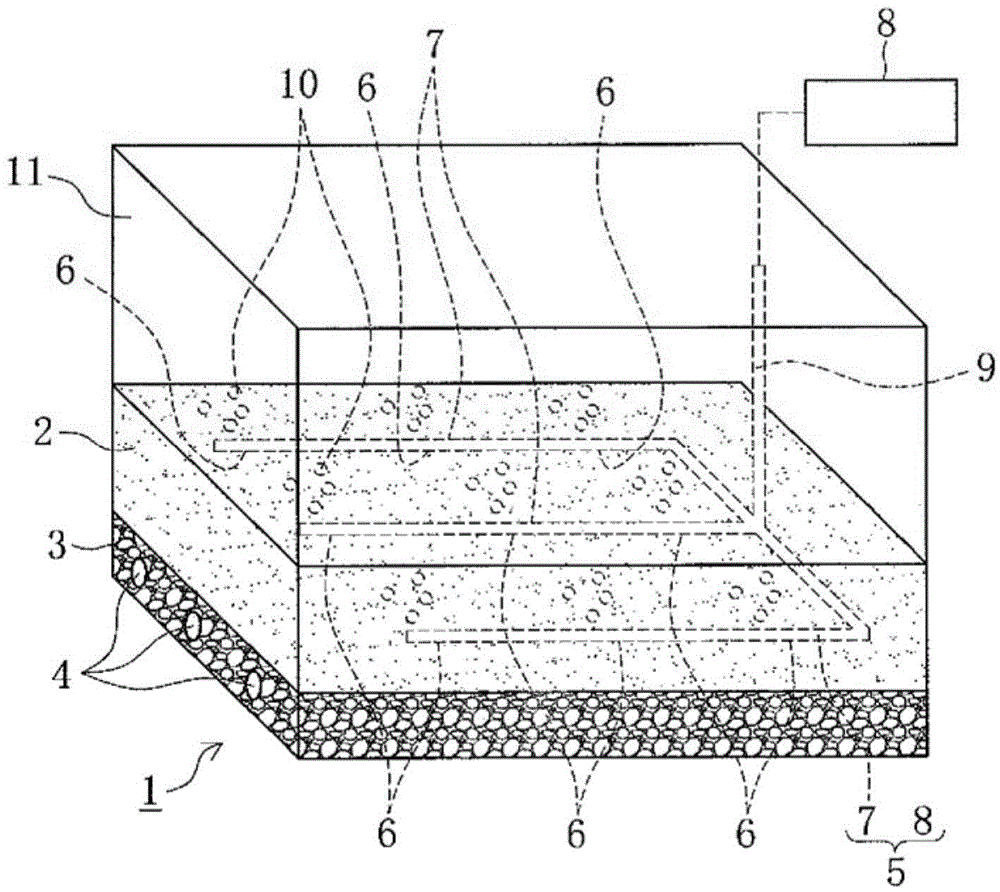

[0031] exist figure 1 Among them, 1 is the seawater infiltration water intake equipment, which absorbs the seawater permeated into the filter sand layer 2 and the support gravel layer 3 arranged on the seabed through the water intake pipe 4 buried in the support gravel layer 3 . The water intake pipe 4 is a pipe with a water intake hole, and is connected with a sump pump to obtain water from the seawater permeating into the filter sand layer 2 and the supporting gravel layer 3 .

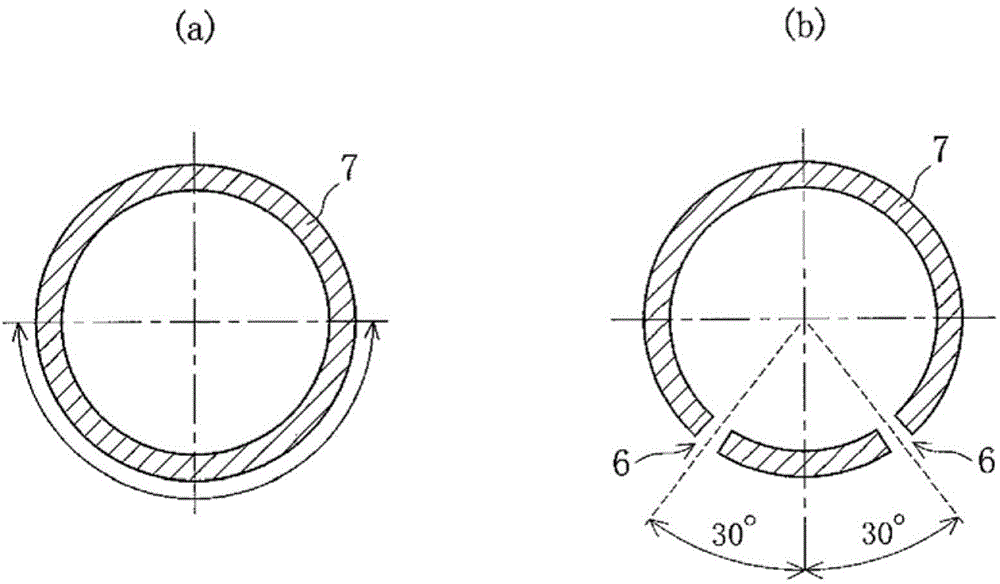

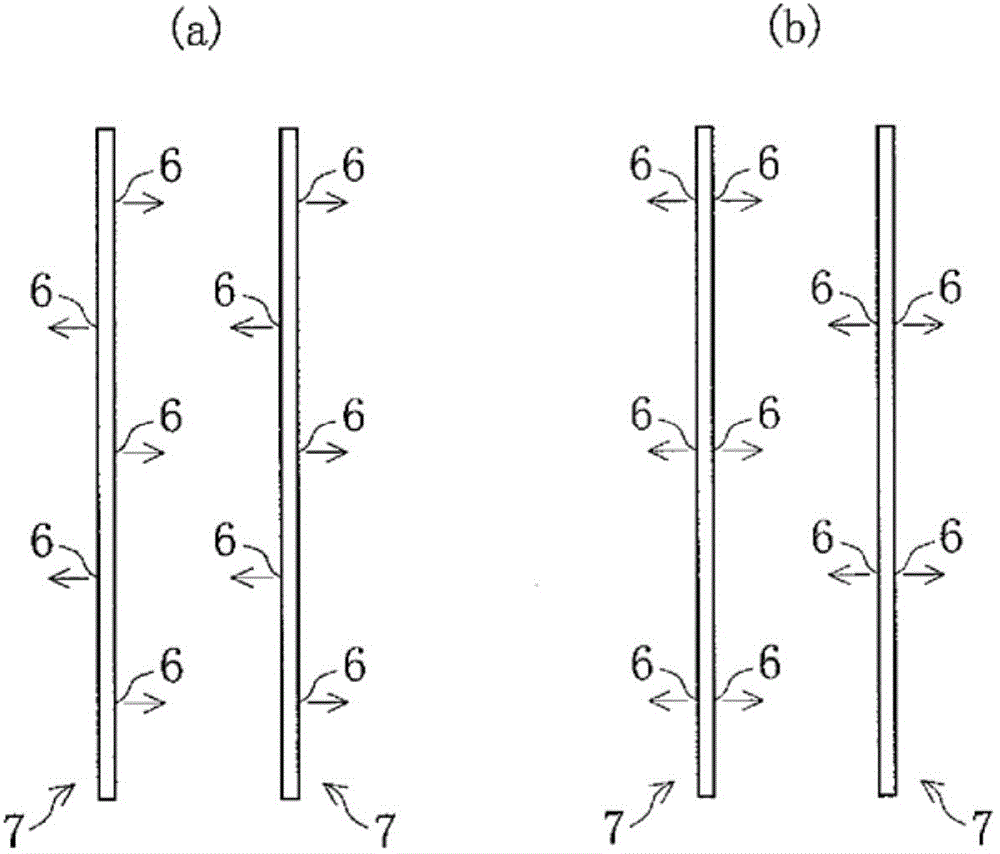

[0032] 5 is the cleaning system of the present invention, which is composed of an air diffuser pipe 7 embedded in the filter sand layer 2 and having an air injection hole 6, and a compressed air delivery device 8 that sends air to the air diffuser pipe 7. The cleaning system removes the filter sand The suspended matter caused by the blockage of the mesh of layer 2 is cleaned.

[0033] In this embodiment, a plurality of diffuser pipes 7 are arranged and embedded in the horizontal direction. Each dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com