Method for optimizing project duration of engineering project based on potential anti-key working procedures

An anti-key, process technology, applied in the field of engineering project schedule control, can solve problems such as redundant decision variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Below in conjunction with example the present invention is further described. Embodiment 1 illustrates the principle of the present invention.

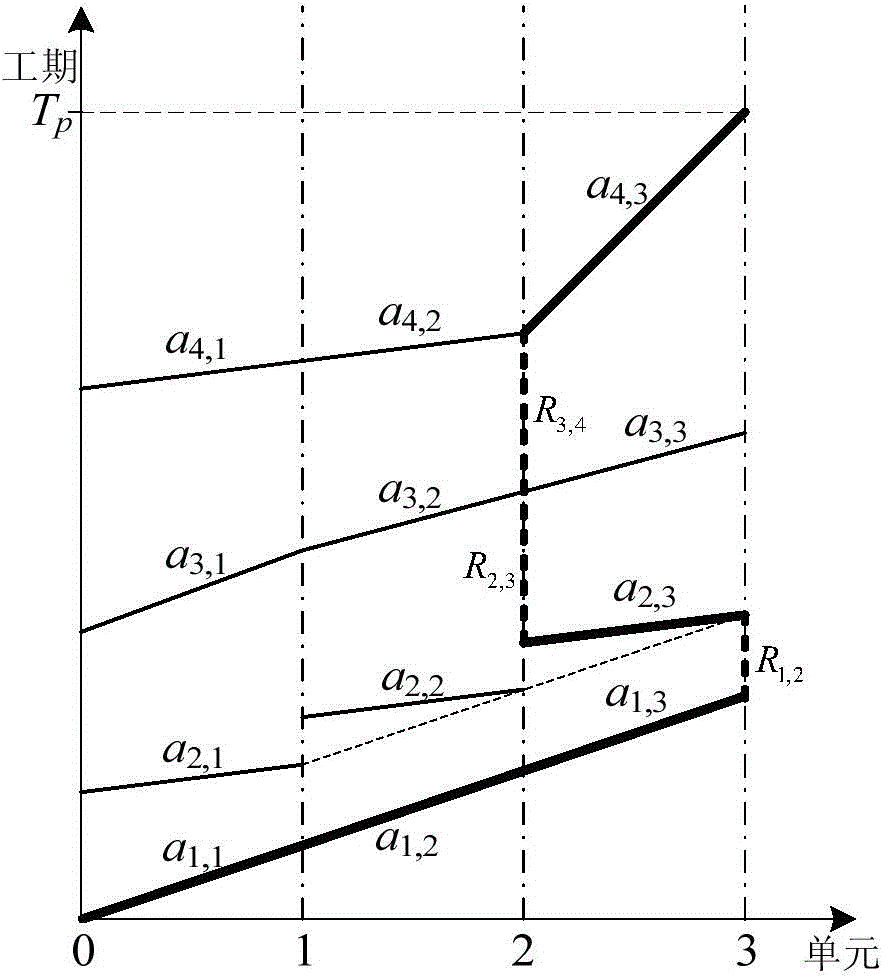

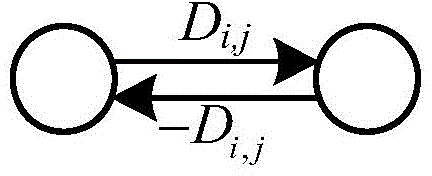

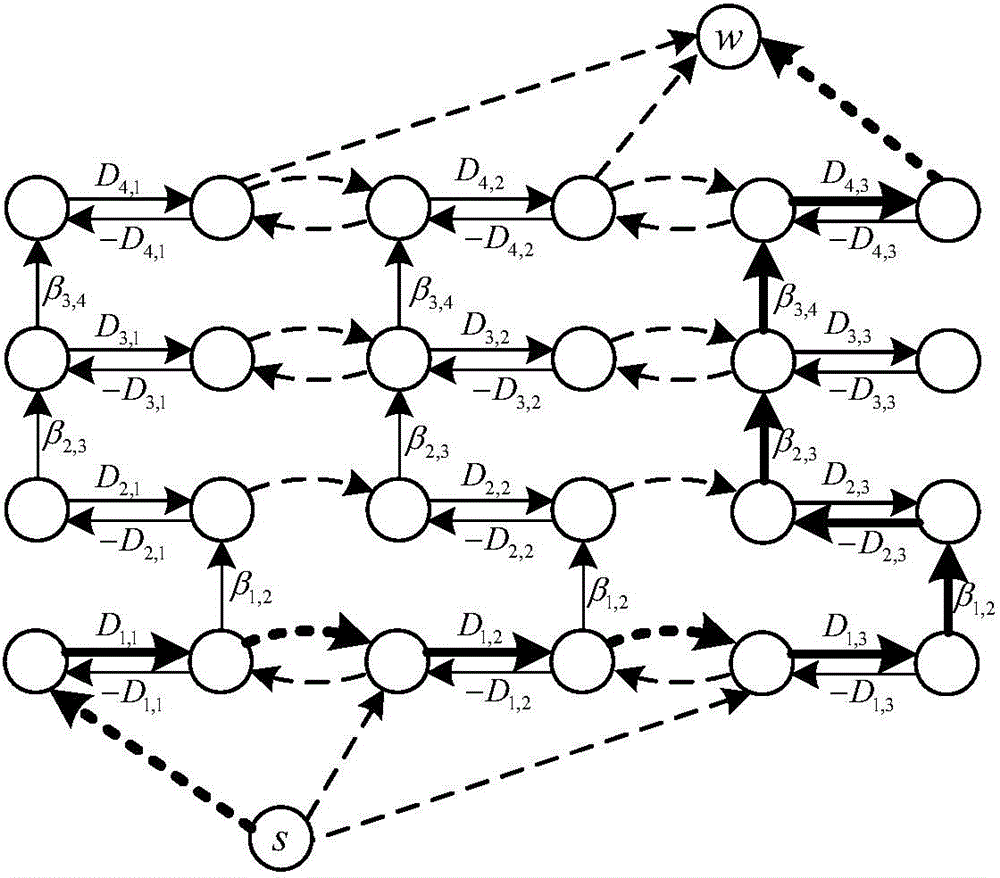

[0080] Assume that a repetitive project consists of M processes, and each process needs to be repeated in N units. Process A i (i=1,...,M) has Ω i Execution modes, where the work efficiency of the kth execution mode is Assumed process A i (i=1,...,M) require to maintain resource constancy constraints, then when process A i After selecting an execution mode, it must work in this execution mode until the end of the process. with a i,j Indicates process A i Subprocess in unit j, Q i,j Indicates the corresponding workload, then the sub-process a i,j Duration D i,j It can be obtained from formula (1).

[0081] D i , j = Q i , j ...

Embodiment 2

[0175] The effects of the present invention will be described below in conjunction with a specific example. like Image 6 as shown, Image 6 A repetitive project is given, including 11 processes and 5 units. For engineering information such as the continuity requirements of the process, the type and amount of constraints of priority relations, and possible execution modes, see Image 6 , looking for a scheduling scheme that minimizes the total duration of the project and minimizes the sum of corresponding interruption times.

[0176] According to the algorithm steps, firstly, the sets X and Y are divided according to the constraint type of the priority relation between the processes and the requirement of work continuity. Process A 3 、A 7 、A 8 and A 10 Due to the existence of work continuity requirements and the determination conditions for potential anti-key processes are met, process A 5 Continuity of work not required, but with immediate predecessor process A 4 Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com