A spiral back-clutch device based on a dual-motor module

A clutch device and screw-type technology, which is used in non-mechanical transmission-operated locks, door/window accessories, handle connections, etc., can solve the problems of high risk, reduced reliability of the lock body, and low reliability, and achieve high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] like Figure 8 As shown, the helical back clutch device based on the double motor module of the present invention includes: a double motor module and a helical back clutch module.

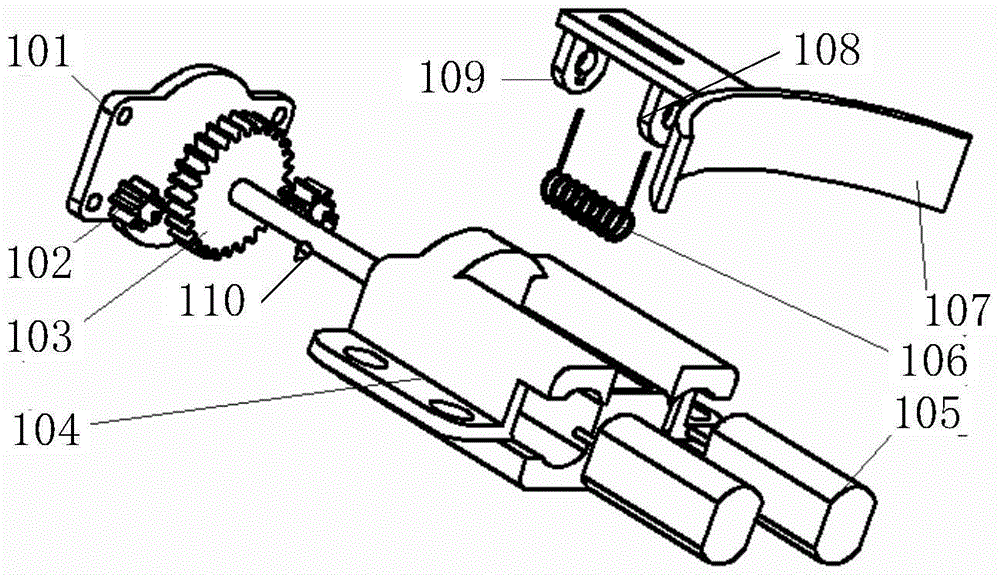

[0025] like Figure 1 to Figure 3 As shown, the dual motor module includes: a cover plate 101, two pinion gears 102, a gear shaft 103, a motor housing 104, two identical motors 105, a torsion spring 106, an arc push plate 107, and a front push plate 108, rear push plate 109 and cross bar 110;

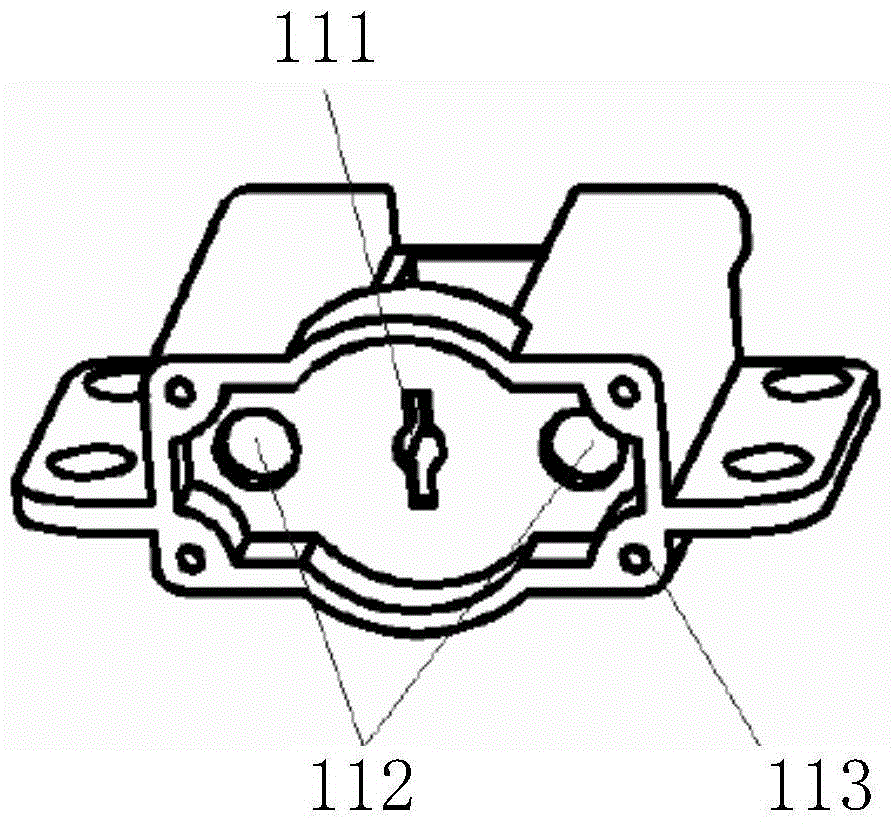

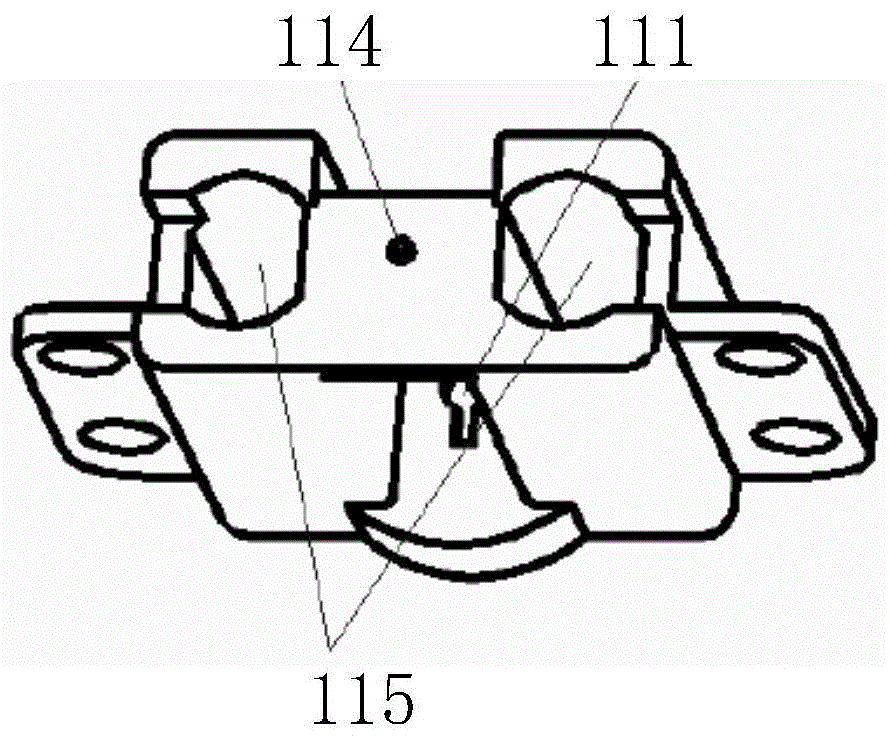

[0026] The gear shaft 103 includes a large gear and a journal, and the large gear and the journal are integrally designed; one end of the motor housing 104 is provided with two motor mounting holes 115 having the same shape as the motor 105 and matching with the gear shaft journal. The second gear shaft hole 114, and the second gear shaft hole 114 is located between the two motor mounting holes 115, the other end is provided with two motor shaft holes 112 matched with the motor shaft of the motor 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com