Environment-friendly type low temperature resistant crude oil demulsifier and preparation method thereof

A crude oil demulsifier and low-temperature-resistant technology, which is applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of poor performance, lower water removal rate, lower reclaimed water settling speed and settling time, etc. The preparation method is simple and easy , good low temperature resistance, good demulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

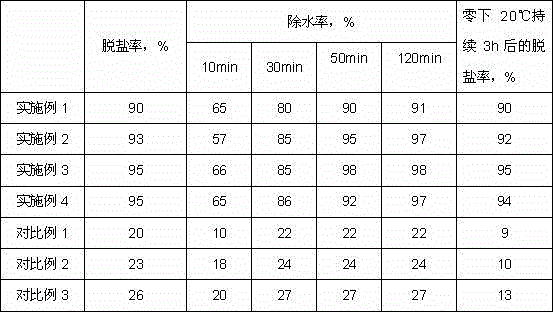

Examples

Embodiment 1

[0023] An environment-friendly low-temperature resistant crude oil demulsifier, including the following components in parts by weight: 28 parts of polyoxyethylene polyoxypropylene block polyether, 4 parts of imperina root, 2 parts of Sophora japonica, 0.2 part of sodium bicarbonate, magnesium sulfate 0.5 part, 1 part of oligosaccharide, 0.7 part of alginate, 0.1 part of aescin, 1 part of decyl glucoside, 0.5 part of cocamidopropyl betaine, 80 parts of water.

[0024] The preparation method of described environment-friendly low temperature resistant crude oil demulsifier comprises the steps:

[0025] Step 1: According to the mass ratio, mix the rhizome of Imperata corydalis and Sophora japonica evenly, crush it to 100 mesh, add it into water, ultrasonicate at 30°C for 3 hours, centrifuge, and take the supernatant to obtain the first extract;

[0026] Step 2, adding sodium bicarbonate, magnesium sulfate, and oligosaccharides to the first extract in sequence, and stirring evenly ...

Embodiment 2

[0030] An environment-friendly low temperature resistant crude oil demulsifier, including the following components in parts by weight: 49 parts of polyoxyethylene polyoxypropylene block polyether, 10 parts of imperina root, 5 parts of Sophora japonica, 0.6 part of sodium bicarbonate, magnesium sulfate 1 part, 3 parts of oligosaccharide, 1.5 parts of alginate, 0.2 part of aescin, 3 parts of decyl glucoside, 2.8 parts of cocamidopropyl betaine, 99 parts of water.

[0031] The preparation method of described environment-friendly low temperature resistant crude oil demulsifier comprises the steps:

[0032] Step 1: According to the mass ratio, mix the rhizome of Imperata corydalis and Sophora japonica evenly, crush it to 200 mesh, add it into water, ultrasonicate at 40°C for 1 hour, centrifuge, and take the supernatant to obtain the first extract;

[0033] Step 2, adding sodium bicarbonate, magnesium sulfate, and oligosaccharides to the first extract in sequence, and stirring evenl...

Embodiment 3

[0037] An environment-friendly low temperature resistant crude oil demulsifier, including the following components in parts by weight: 30 parts of polyoxyethylene polyoxypropylene block polyether, 5 parts of imperina root, 3 parts of Sophora japonica, 0.3 part of sodium bicarbonate, magnesium sulfate 0.5 parts, 2 parts of oligosaccharides, 0.9 parts of alginate, 0.1 parts of aescin, 1 part of decyl glucoside, 0.8 parts of cocamidopropyl betaine, 84 parts of water.

[0038] The preparation method of described environment-friendly low temperature resistant crude oil demulsifier comprises the steps:

[0039] Step 1: According to the mass ratio, mix the rhizome of Imperata corydalis and Sophora japonica evenly, crush it to 200 mesh, add it into water, ultrasonicate at 35°C for 2 hours, centrifuge, and take the supernatant to obtain the first extract;

[0040] Step 2, adding sodium bicarbonate, magnesium sulfate, and oligosaccharides to the first extract in sequence, and stirring e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com