Dust collector tension pulley frame dislocation balancing structure

A technology of balanced structure and tensioner frame, applied in vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of tensioner frame deviation, tensioner deviation, and inability to observe the vacuum cleaner in real time, and achieve the goal of overcoming tensioner deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

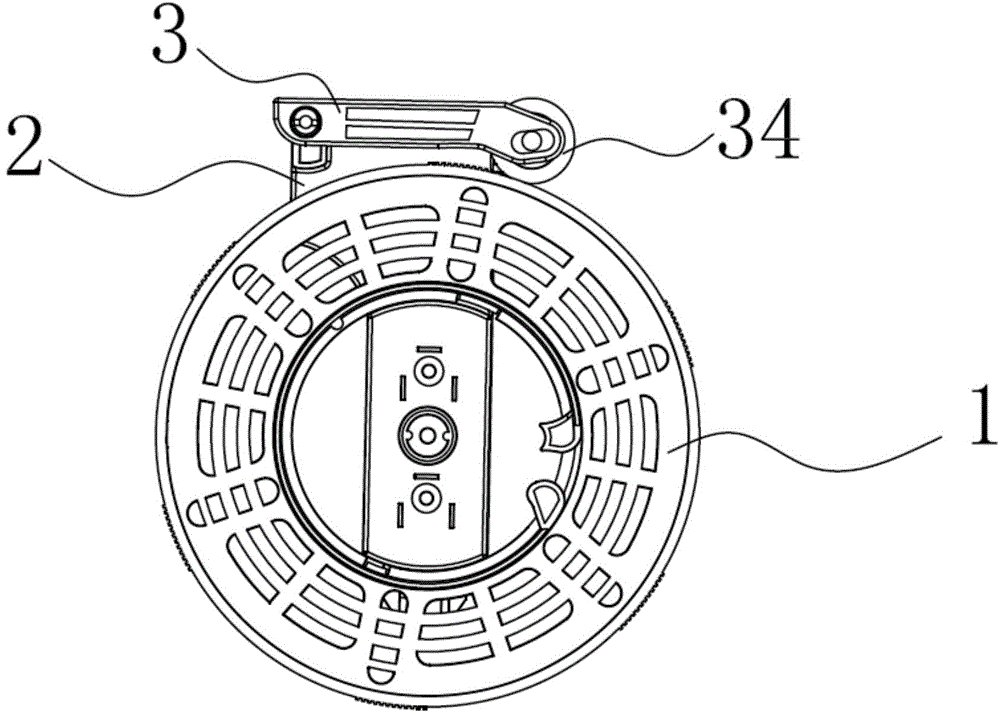

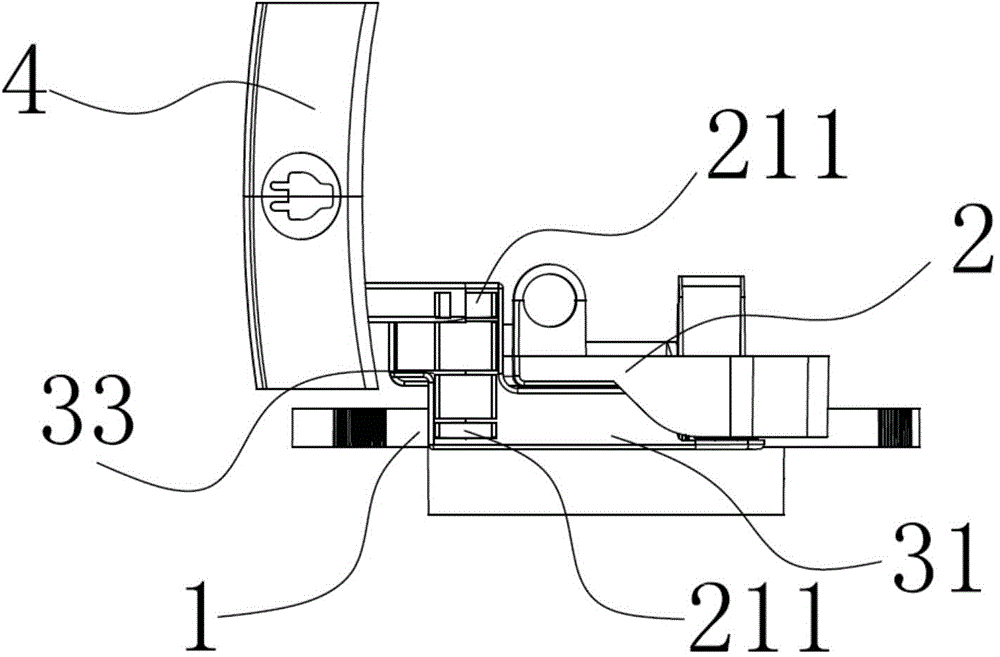

[0038] In order to achieve the purpose of the present invention, as Figure 2-7 As shown, in some embodiments of the dislocation balance structure of the vacuum cleaner tensioner frame of the present invention, it is installed at the reel 1, which includes a tensioner frame bracket 2 and a tensioner frame frame 3, and the tension wheel frame bracket 2 is rotatably connected to The rotating shaft 11 of the reel 1 is provided with a shaft body 21 transversely on the tensioner bracket bracket 2, and the first connecting portion 211 is formed at both ends thereof; the tensioner frame 3 includes a first frame unit 31 and a second Frame body unit 32, the side parts of the first frame body unit 31 and the second frame body unit 32 are fixedly connected or integrally formed to form overlapping joints 33, and the two outer sides of the joints 33 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com