Terminal extraction jig

A terminal and jig technology, which is applied in the assembly/disassembly of contacts, fixing/insulating contact members, electrical components, etc., can solve the problem of unstable insertion posture of the terminal pull-out jig, and the locking of the lance and the terminal metal piece. Eliminate problems such as labor and work, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

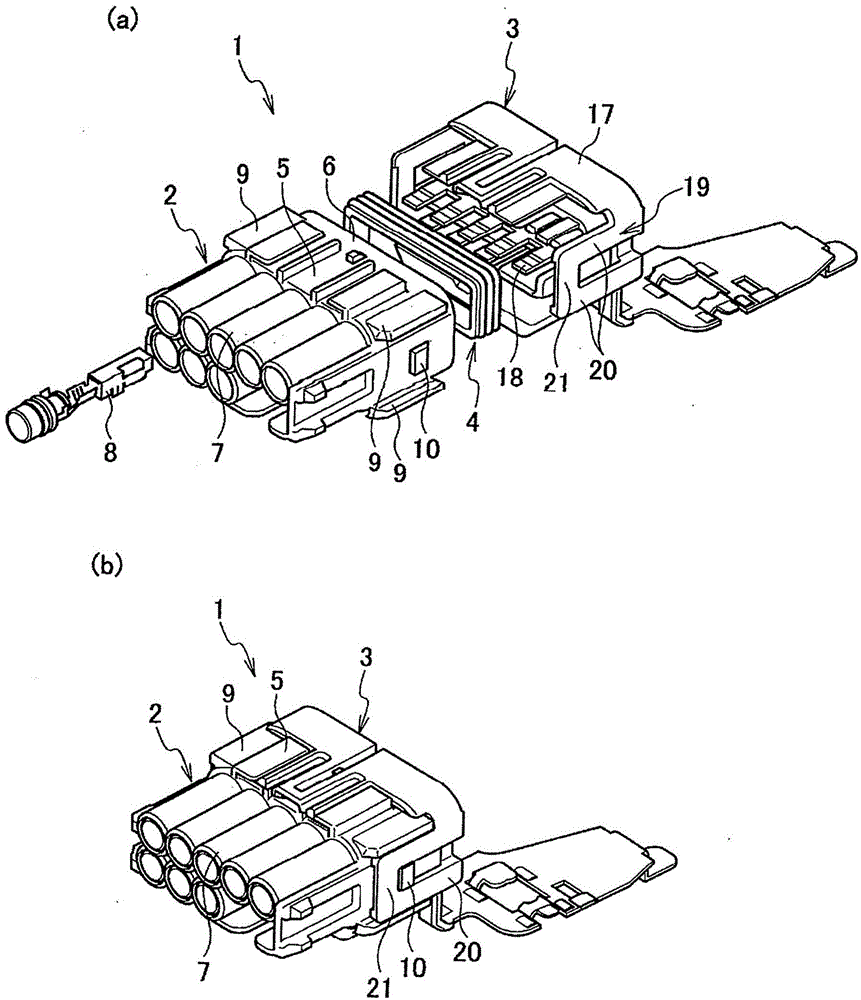

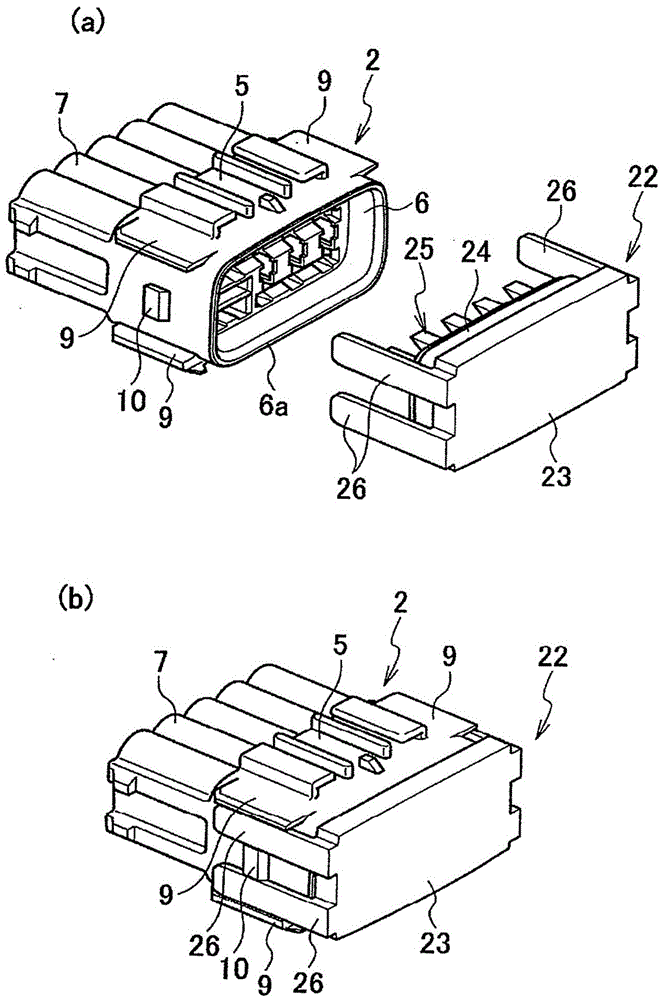

[0035] use figure 1 -5 The first embodiment will be described.

[0036] The terminal extraction jig 22 of the first embodiment is used for figure 1 The illustrated connector 1 can release the engagement state between the terminal metal piece 8 accommodated in the terminal accommodation chamber 11 of the connector 1 and the locking lance 12 engaged with the terminal metal piece 8, and the terminal metal piece The member 8 is pulled out from the terminal accommodating chamber 11.

[0037] Such as figure 1 As shown, the connector 1 includes: a first connector 2; a second connector 3 as a counterpart connector, which is fitted with the first connector 2; and a waterproof gasket 4, which is clamped on the first connection Between the connector 2 and the second connector 3, waterproofing is performed.

[0038] The first connector 2 includes: a connector housing 5; a cover 6 provided on one end side of the connector housing 5 and fitted to the second connector 3; and a wire lead-...

no. 2 Embodiment approach >

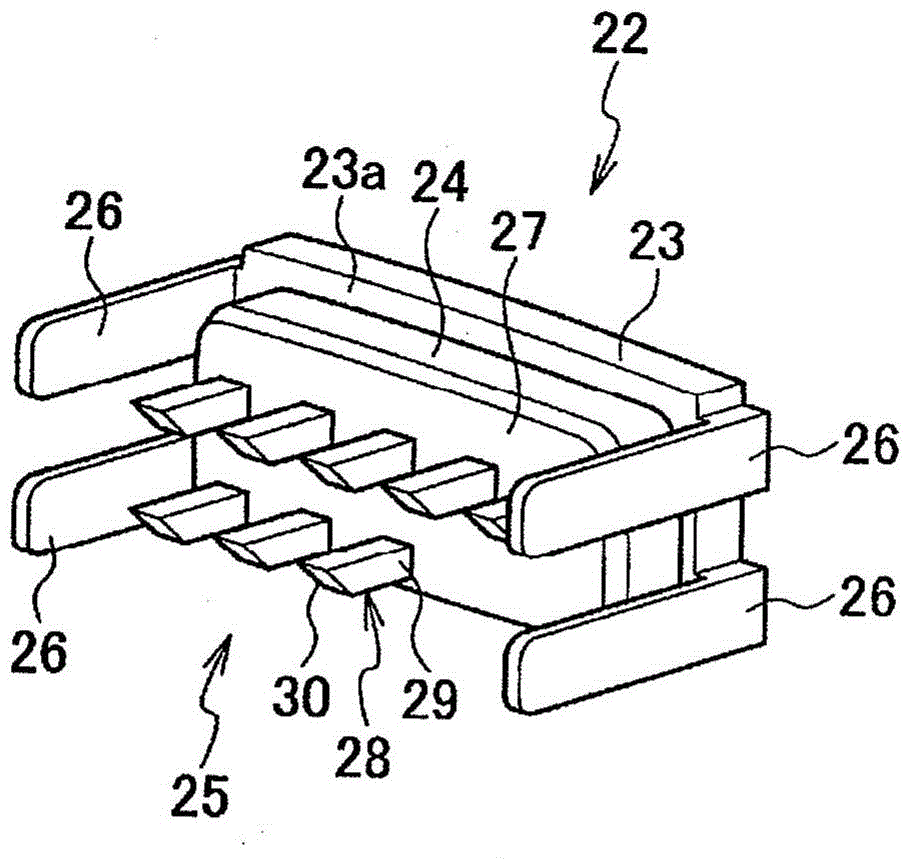

[0054] Next, explain Image 6 (a), 6(b), and 2nd Embodiment shown in 7. In the second embodiment, for the same components as those of the first embodiment, in Image 6 (a), 6(b), and 7 are shown with the same reference numerals as those of the first embodiment, and overlapping descriptions are omitted.

[0055] In the terminal extraction jig 33 of the second embodiment, the leading ends of the guide pieces 26, 26 are connected by the connection holding portion 31, and the inside surrounded by the guide pieces 26, 26, and the connection holding portion 31 is formed as a rectangular through hole. .

[0056] Such as Image 6 As shown in (a) and 6(b), the connection holding part 31 is provided between the ribs 9 and 9 of the connector housing 5, and like the connection holding part 21 of the second connector 3, it is fitted with the connector housing 5. The retaining protrusion 10 is snapped together. When the connection holding portion 31 is engaged with the fitting holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com