Optical device and manufacturing method therefor

A processing method and technology for optical devices, which are applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of reduced brightness and reduced light export efficiency, and achieve the effect of improving export efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

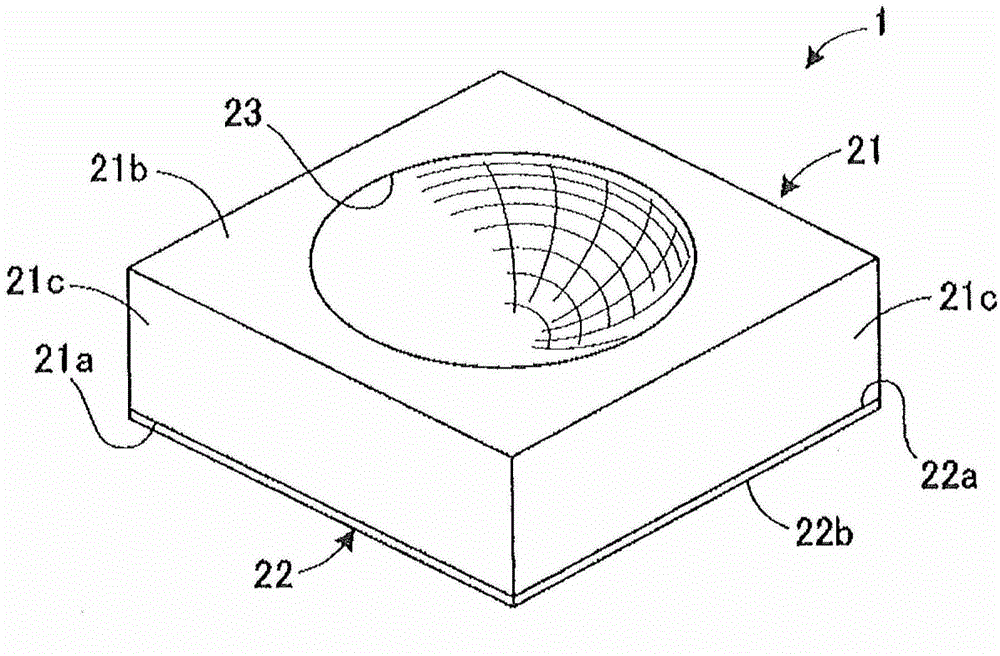

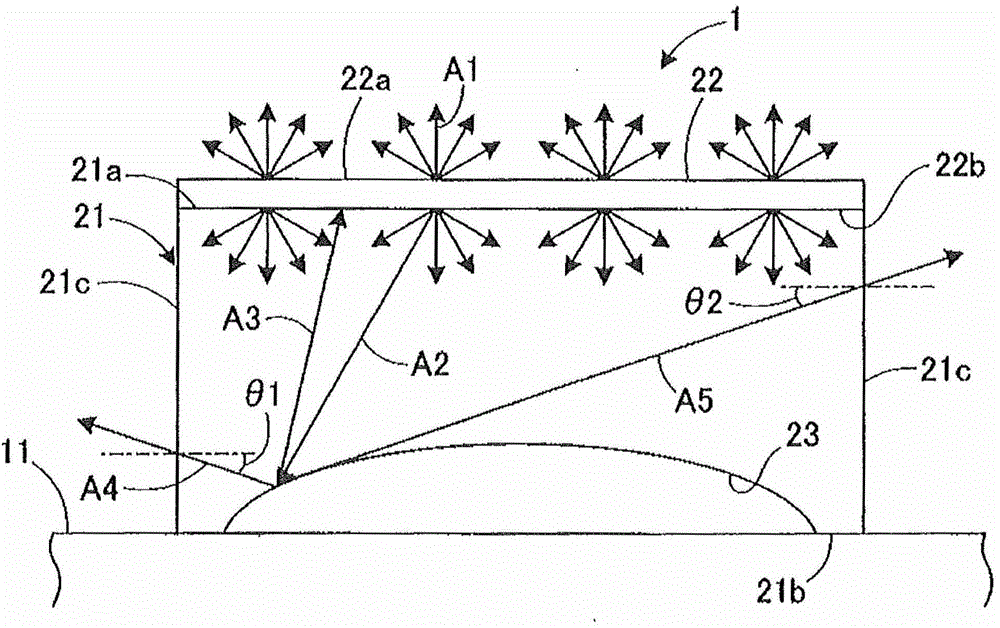

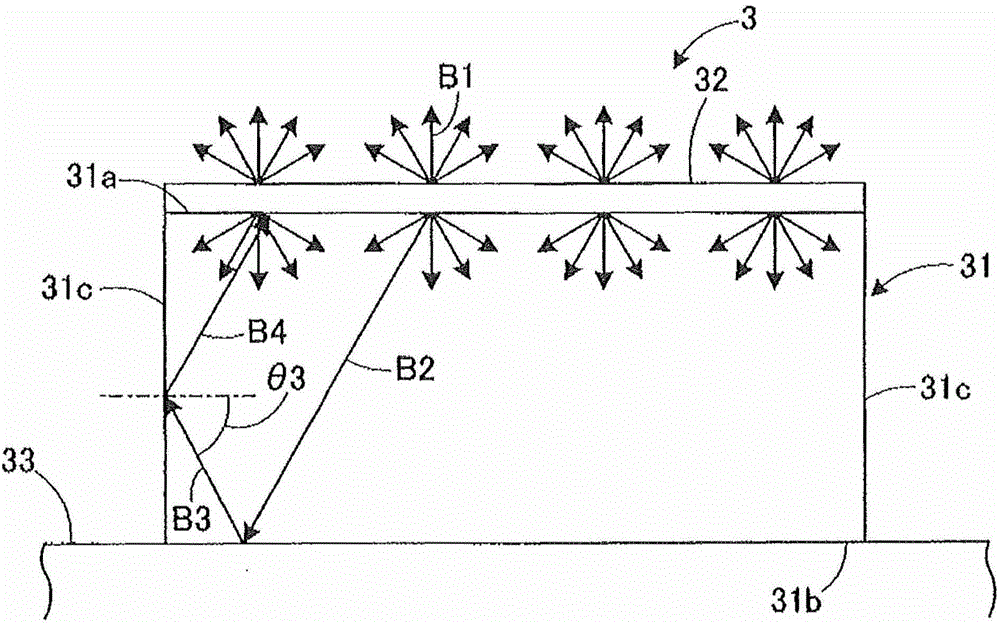

[0031] The optical device and its processing method will be described with reference to the drawings. First, refer to figure 1 and figure 2 , Describe the optical device. figure 1 It is a perspective view showing an example of the optical device from the back side. figure 2 It is a cross-sectional view for explaining the light emission state of the optical device.

[0032] Such as figure 1 and figure 2 As shown, the optical device 1 is wire-bonded or flip-chip packaged on the base 11 (in figure 1 Not shown in the middle). The optical device 1 is configured to include a substrate 21 and a light-emitting layer 22 formed on the front surface 21 a of the substrate 21. The substrate 21 is used as a substrate for crystal growth, from a sapphire substrate (Al 2 O 3 Substrate), gallium nitride substrate (GaN substrate), silicon carbide substrate (SiC substrate), gallium oxide substrate (Ga 2 O 3 Substrate) to select. The substrate 21 is preferably transparent.

[0033] The light-emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com