Online diagnosis device and method for large-scale rotating machinery equipment peaking-shaft system

A technology of large-scale rotating machinery and diagnostic devices, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., it can solve the problem of bearing bush extrusion wear, bearing bush temperature rise, and it is impossible to directly know whether the top shaft oil pump is genuine or not. lift etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

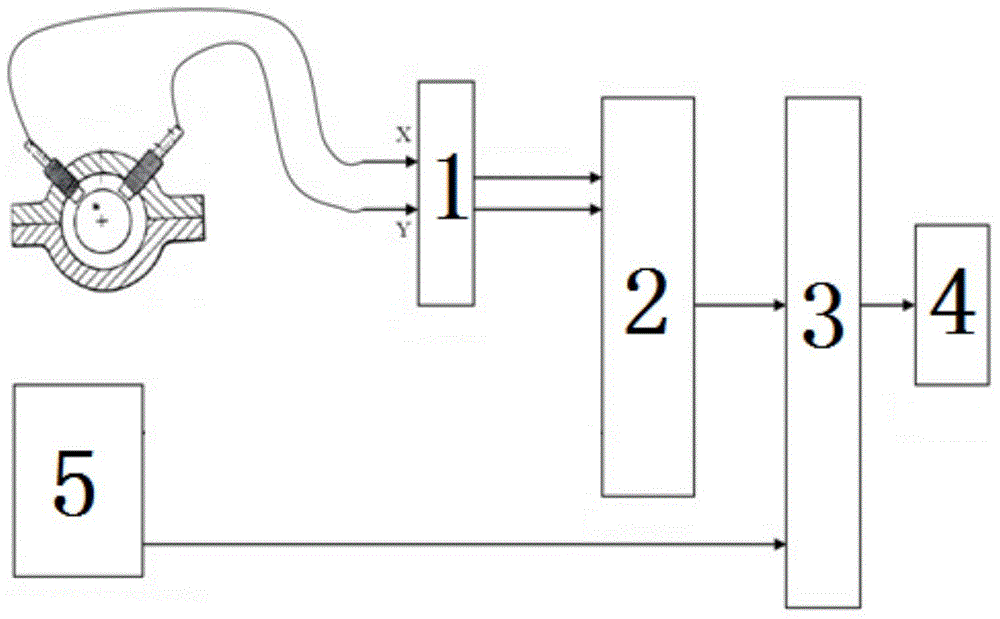

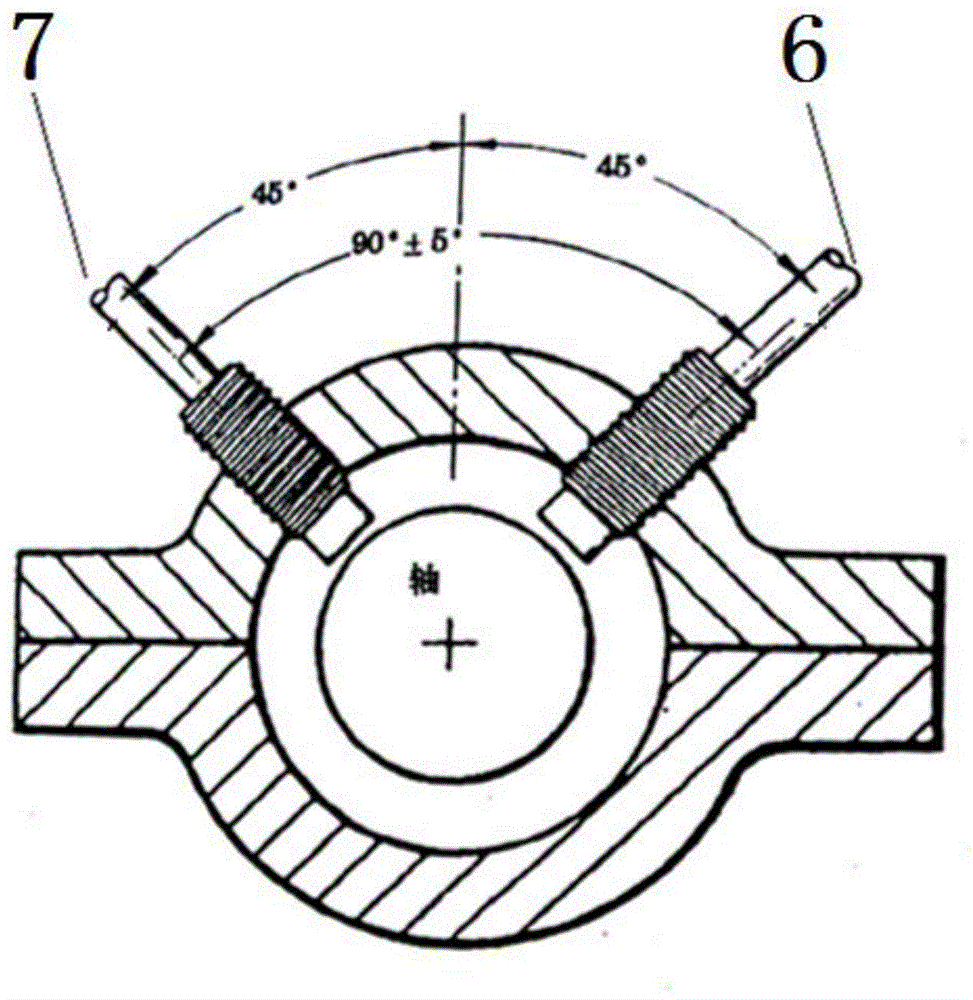

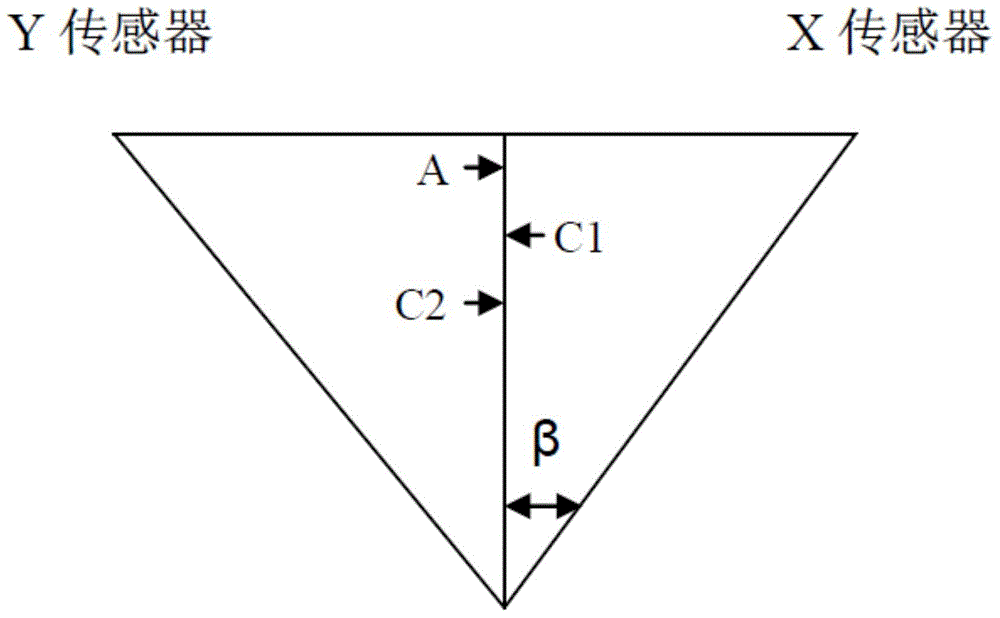

[0082] An online diagnostic device for jacking shaft systems of large rotating mechanical equipment (such as steam turbines, coal mills, etc.). This manual takes the steam turbine as an example, and this device belongs to the protection system for the safe operation of the steam turbine. Its function is: before the turning of the steam turbine, it can display the lifting height of the shaft diameter of the steam turbine rotor at each bearing pad, and the detection accuracy can reach the micron level, so as to ensure the “reasonable” wear of the steam turbine bearing pad, which can greatly prolong the life of the steam turbine bearing pad.

[0083] The device collects data through the buffer interface on the front panel of the steam turbine monitoring instrument (abbreviation: TSI), so it will not affect the safe operation of the unit. Since the system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com