Cleaning equipment

A technology for cleaning equipment and cleaning fluid, which is applied in nonlinear optics, instruments, optics, etc. It can solve the problems of easily polluting glass substrates, easily carrying a large number of bacteria, and easily remaining bacteria, so as to achieve easy popularization and application, simple structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

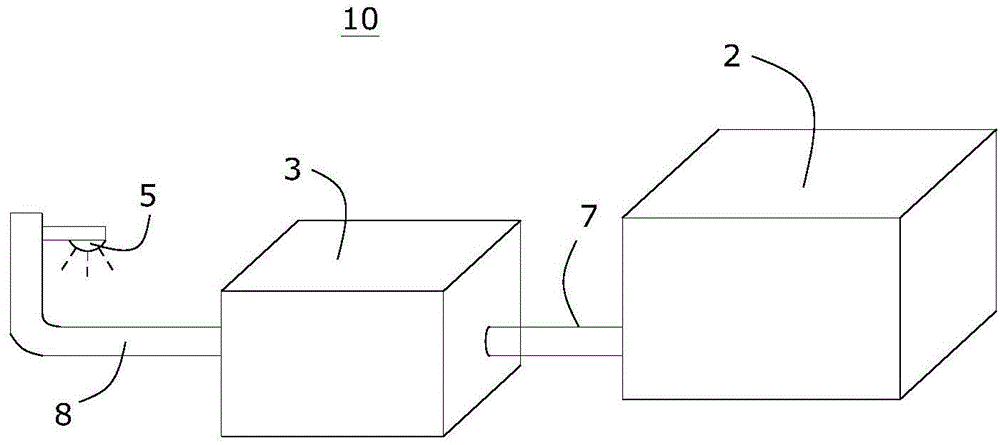

[0024] figure 1 It is a structural schematic diagram of an embodiment of the cleaning equipment according to the present invention. The cleaning device 10 includes a liquid storage tank 2 , a sterilizing device 3 connected to the liquid storage tank 2 through a pipeline 7 , and a nozzle 5 connected to the sterilizing device 3 through a pipeline 8 . The nozzle 5 can directly spray the cleaning liquid onto the object to be cleaned so as to remove the substances on the surface of the object to be cleaned. The cleaning device 10 also includes a recovery device (not shown), which can recover the used cleaning liquid and reuse it after a series of treatments.

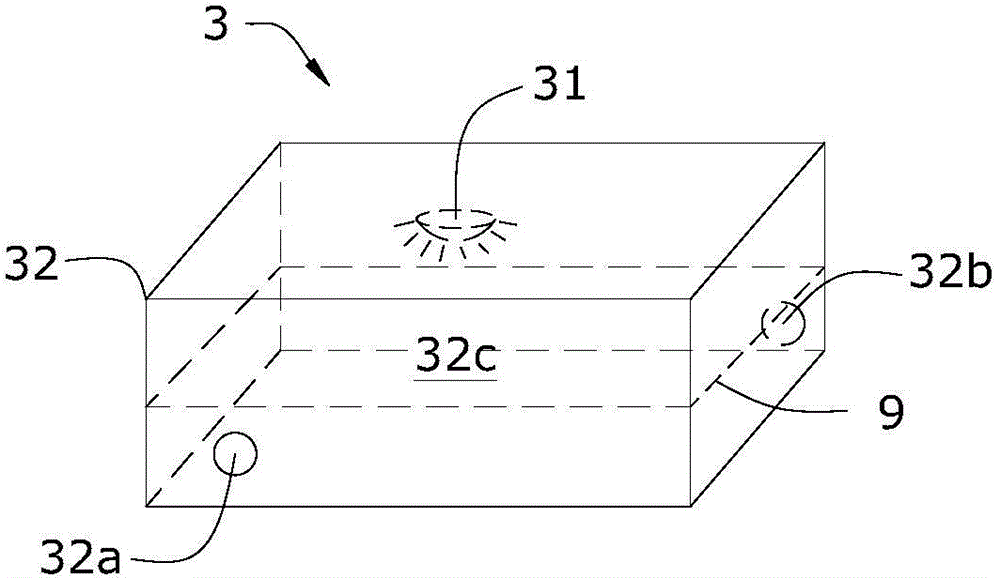

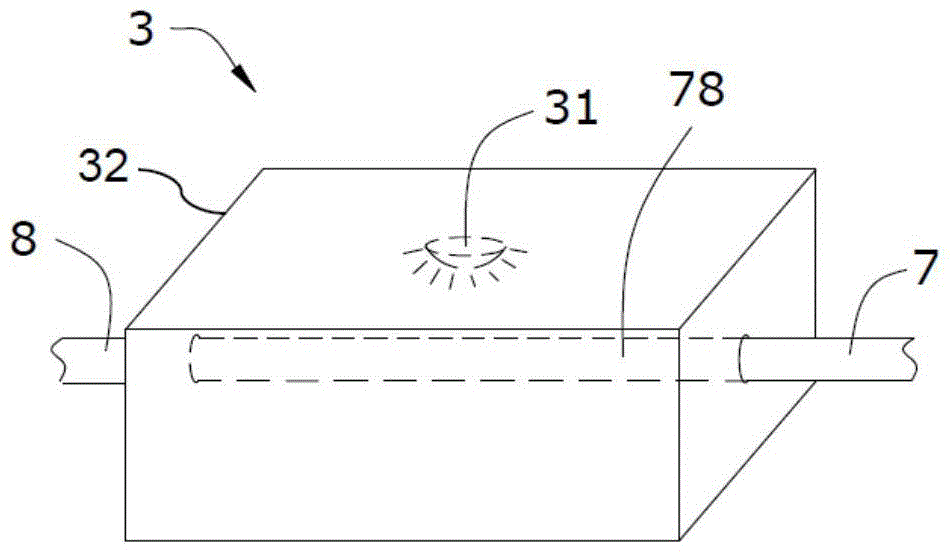

[0025] In this embodiment, the sterilizing device 3 includes an ultraviolet lamp 31 that can sterilize the cleaning solution (see figure 2 , image 3 , Figure 4 and Figure 5 ). The ultraviolet lamp 31 generates u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com