Armature insulation and voltage resistance testing device

A technology of withstand voltage test and armature insulation, applied in the direction of testing dielectric strength, etc., can solve the problems of melting, low test efficiency, and high requirements on the rotation accuracy of the armature rotating mechanism, and achieve the effect of simple control process and high-efficiency test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

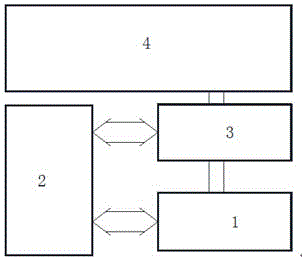

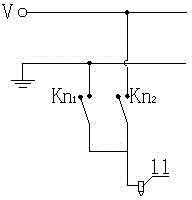

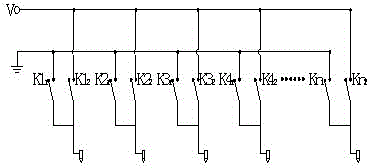

[0012] Such as figure 1 As shown, the armature insulation withstand voltage test equipment of the present invention consists of an insulation withstand voltage tester 1 , a host computer 2 , a voltage switching test device 3 and an armature pressurization device 4 . The insulation withstand voltage tester 1 is used to generate the voltage required in the testing process. Those skilled in the art should understand that the insulation withstand voltage tester 1 proposed here is a common insulation withstand voltage tester currently available in the market, and the output voltage of this type of insulation withstand voltage tester can be set according to actual needs. According to the embodiment of the present invention, the insulation withstand voltage tester 1 can be any insulation withstand voltage tester available in the market, for example, the CS2676N insulation withstand voltage tester produced by Nanjing Changsheng Instrument Co., Ltd. can be used. The upper computer 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com