Soft measuring method of axial deformation quantity of rectangular rubber sealing ring based on flexible screwing assembly

A rubber sealing ring, axial deformation technology, applied in measuring devices, instruments, etc., can solve the problems of low modulus, incompressibility, affecting the reliability of automatic assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

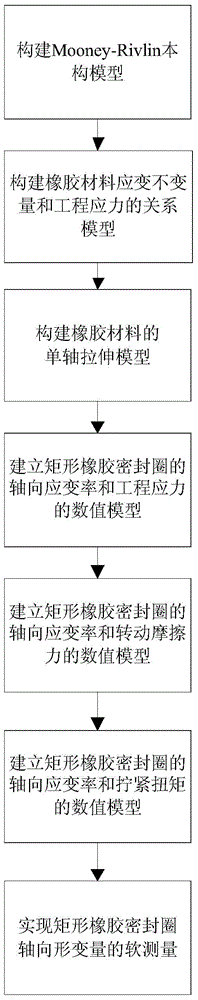

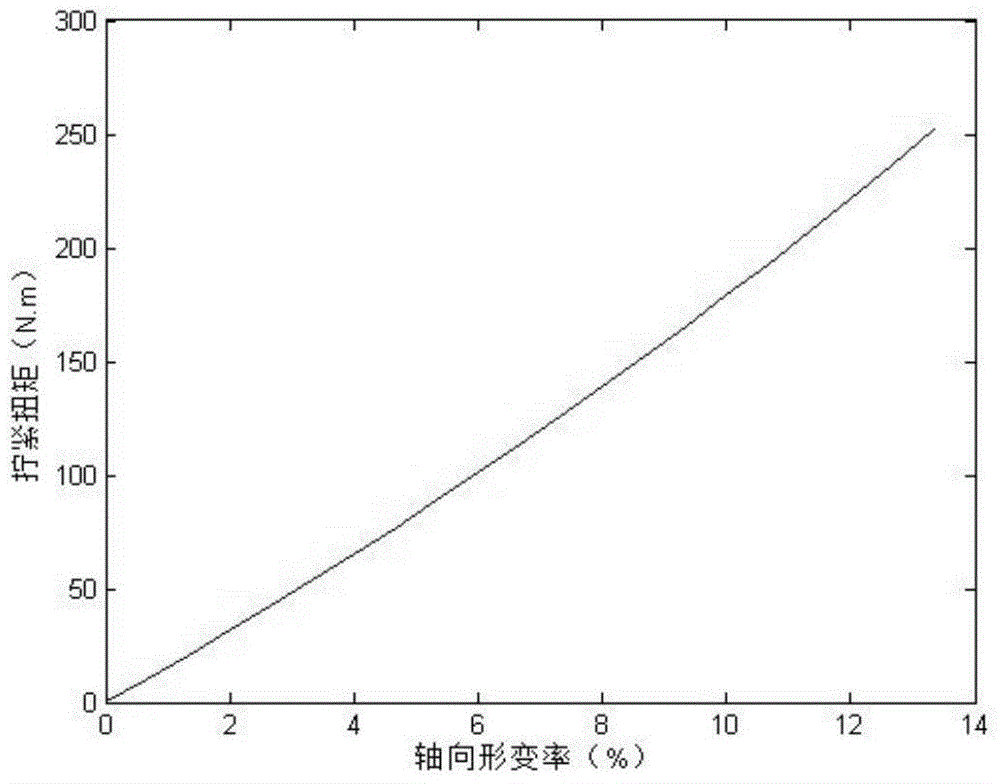

[0040] The invention first utilizes the Mooney-Rivlin constitutive relation model of the rubber material to obtain the relation model between the strain invariant of the rubber material and the engineering stress. Through the uniaxial tensile model of the rubber material, the expression of the strain invariant is obtained, and the expression of the axial strain rate and the axial engineering stress of the rectangular rubber sealing ring is obtained by combining the relationship model between the strain invariant of the rubber material and the engineering stress, so that It reflects the axial stress-strain relationship of the rectangular rubber sealing ring. At the same time, the relationship model between axial strain rate and engineering stress is transformed into the relationship model between axial strain rate and engineering rotational ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com