Normally closed solenoid valve with protection device

A technology of normally closed solenoid valve and protection device, applied in valve device, fuel injection device, valve operation/release device, etc., can solve problems such as adverse influence of hydraulic device, damage of hydraulic device, poor safety, etc., to improve strain capacity and work stability, flexible control, protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

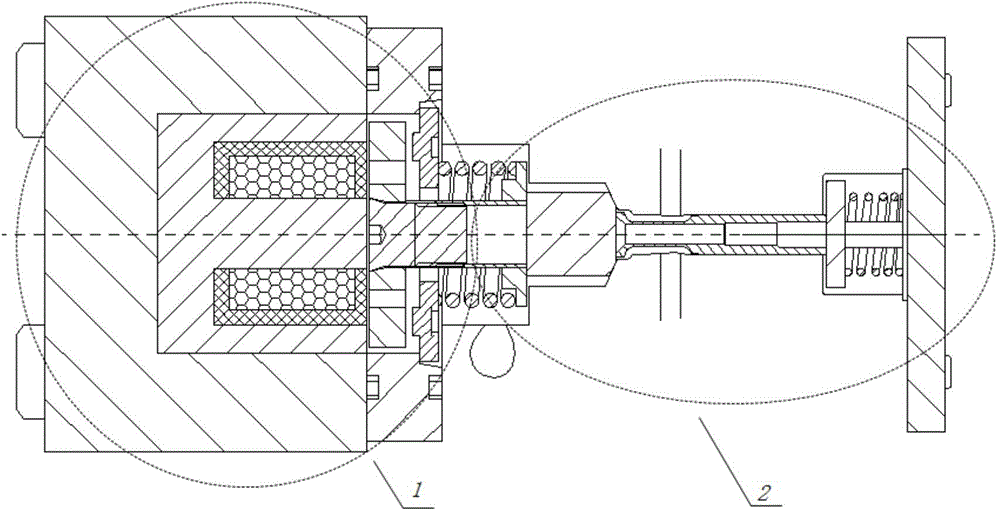

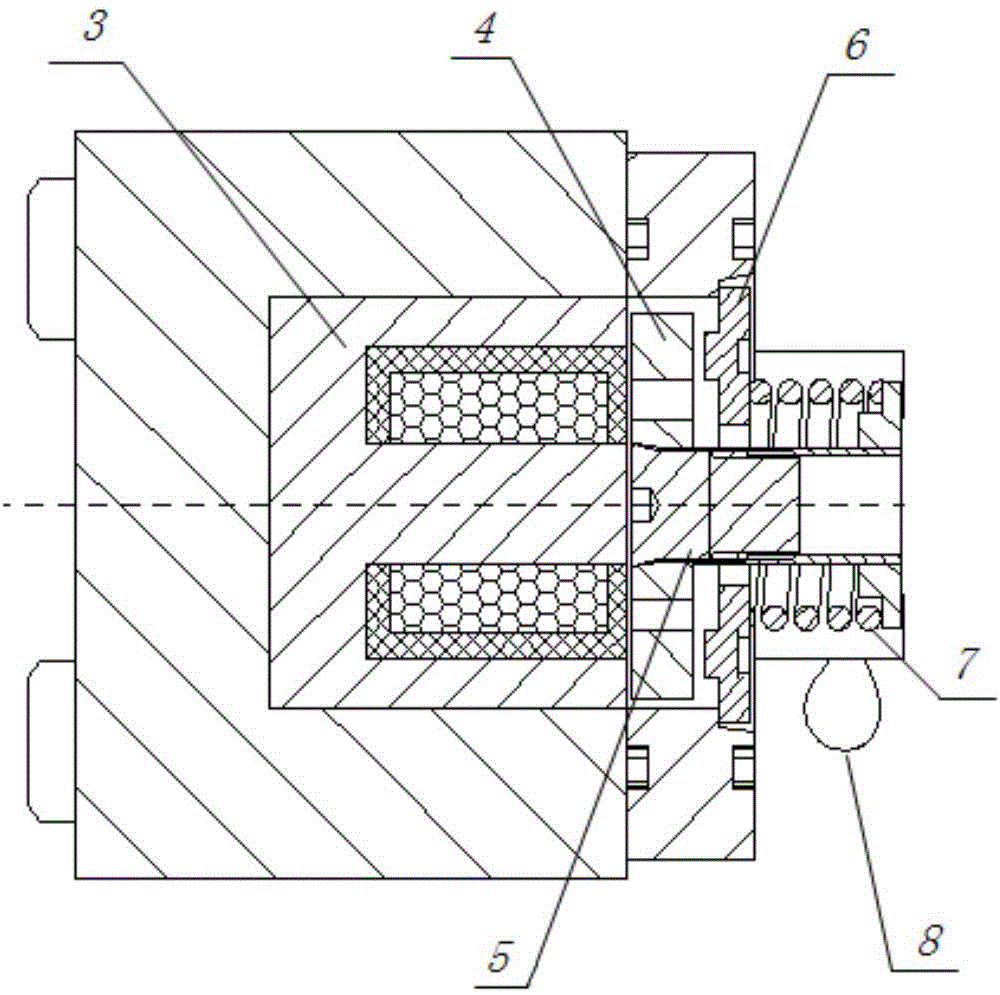

[0016] Combine Figure 1~3 , This device includes solenoid valve 1 and drain valve 2. The solenoid valve 1 includes a solenoid coil 3, an armature 4, a solenoid valve stem 5, a solenoid valve spring seat 6, a solenoid valve spring 7 and an oil drain circuit 8. The drain valve 2 includes a connecting sleeve 9, a drain cone valve 10, an oil inlet oil path 12, a drain valve stem 14 and a drain valve spring 15. The solenoid valve 1 and the drain valve 2 are connected by an interference fit through the solenoid valve stem 5 and the drain valve connecting sleeve 9.

[0017] When the solenoid valve is not powered on, the traditional normally open valve's drain circuit is normally open, and the fuel flows back to the fuel tank through the drain circuit; when the solenoid valve is powered on, the solenoid valve closes the drain circuit, and the fuel can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com