Pressure barrel and water purifier with same

A technology for pressure barrels and sealing parts, applied in pressure vessels, mechanical equipment, water/sewage treatment, etc., can solve problems such as pressure barrel leakage, water storage layer, pressure-holding layer seal failure, water purifier failure, etc., to achieve reliable The effect of sealing and eliminating air leakage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

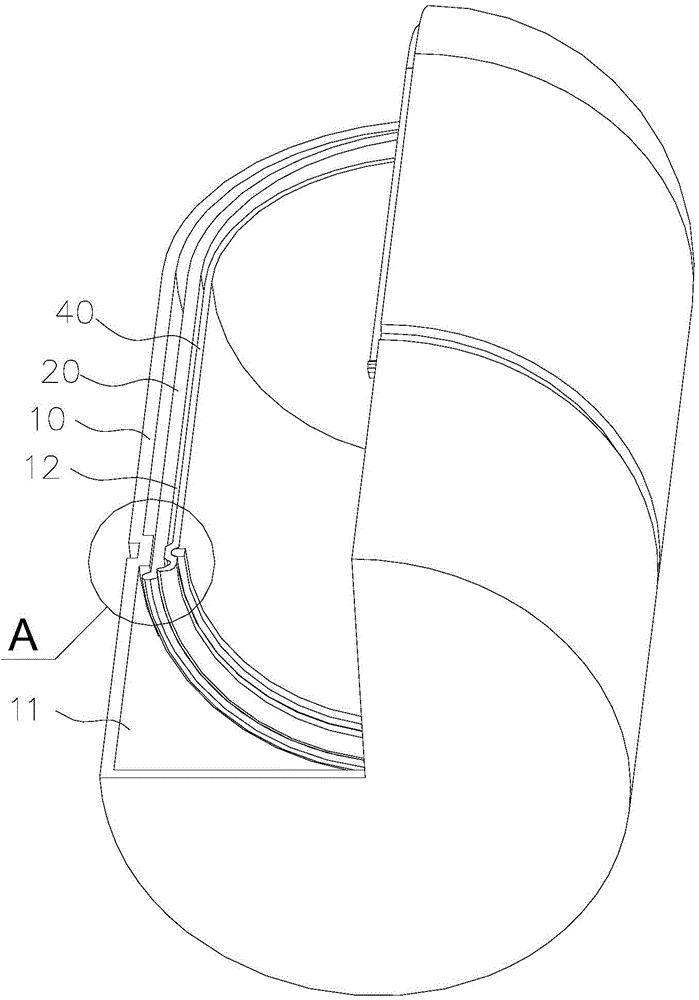

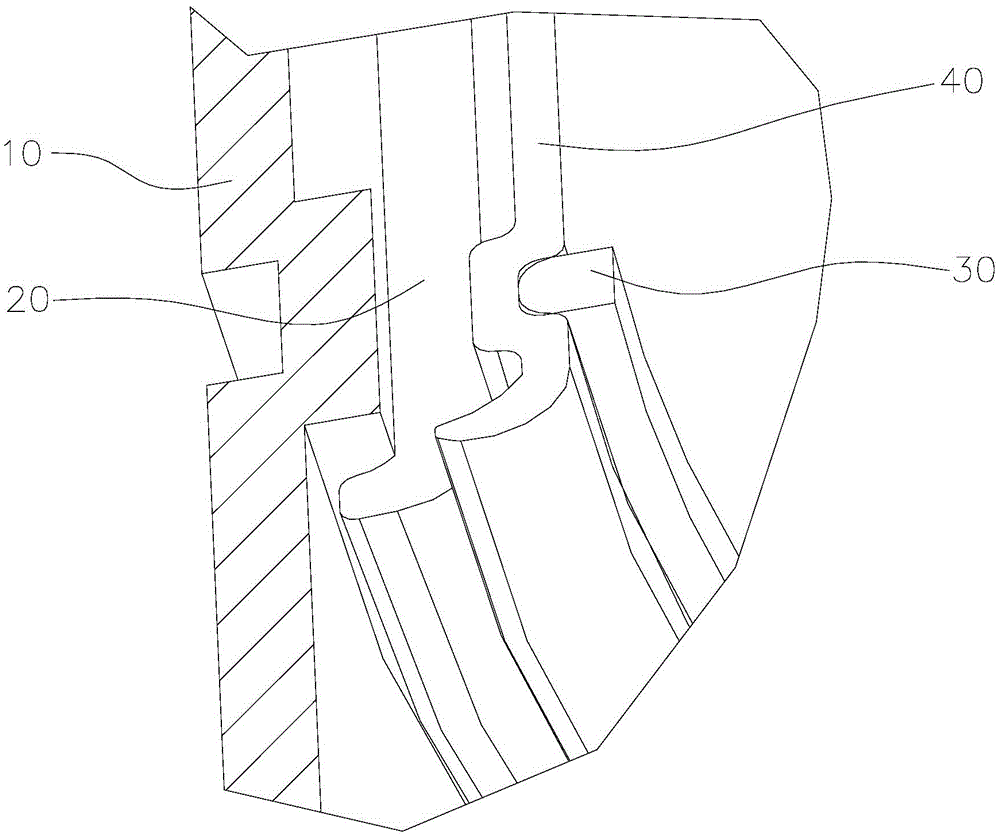

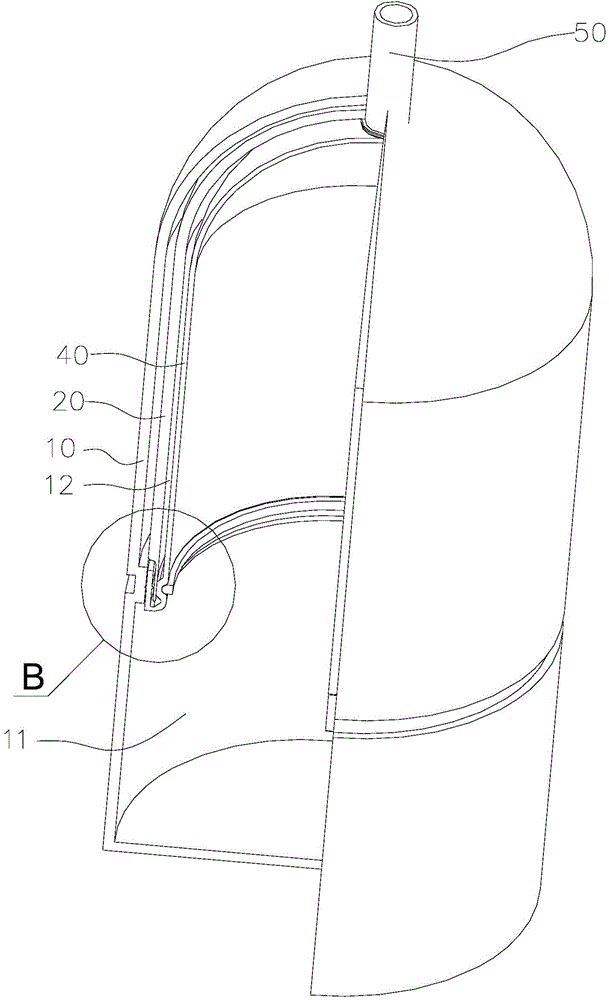

[0030] In one embodiment of the present invention, a pressure barrel is provided, such as image 3 and Figure 4 As shown, the pressure barrel includes a cylinder body 10, a compression ring 30 and a diaphragm 40, wherein the cylinder body 10 has an inner cavity, and an annular boss 13 protruding into the inner cavity is provided on the peripheral wall of the inner cavity. The diaphragm 40 has a peripheral first seal 41 . The compression ring 30 is pressed against the first sealing part 41 of the diaphragm 40, so that the first sealing part 41 is sealed with the annular boss 13, and the gap between the diaphragm 40 and the lower inner wall of the cylinder body 10 is A pressure-holding chamber 12 is formed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com