Hydraulic suspension

A hydraulic mount and pressure plate technology, applied in the direction of shock absorbers, springs, spring/shock absorbers, etc., can solve the problems of unfavorable low-frequency and large-value vibration, decoupling diaphragm damage, dynamic hardening, etc., and achieve favorable isolation Effects of vibration, reduction of suspension dynamic stiffness, and product performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

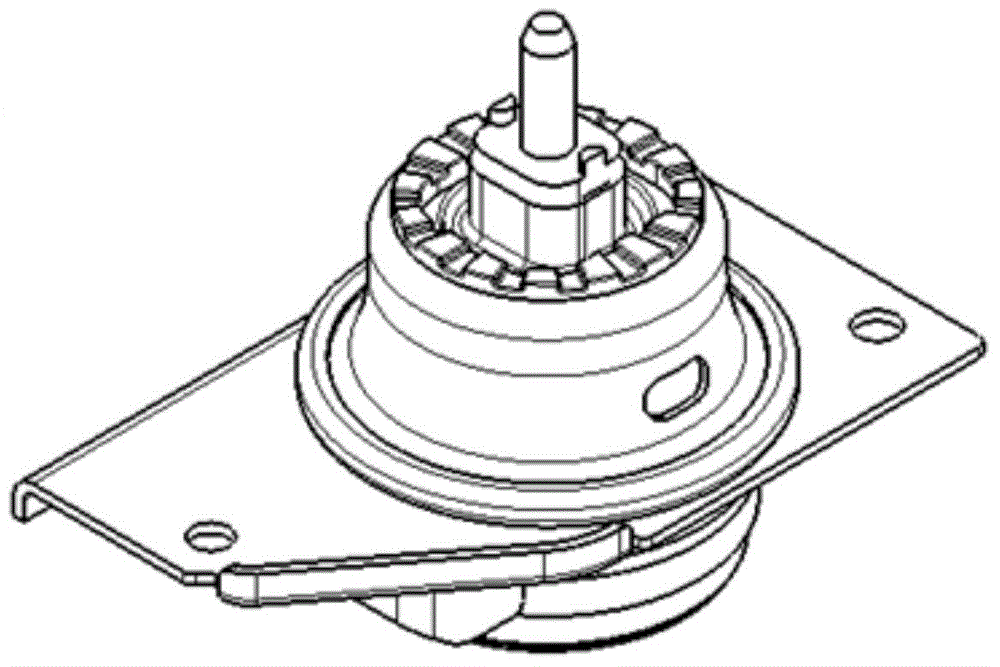

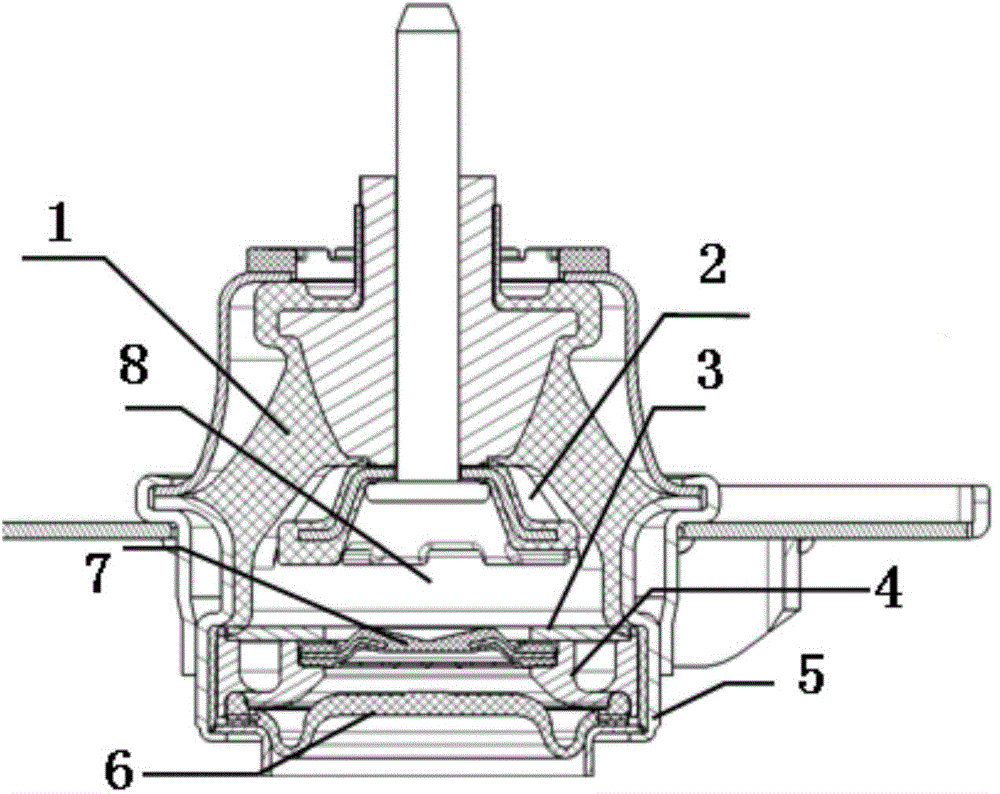

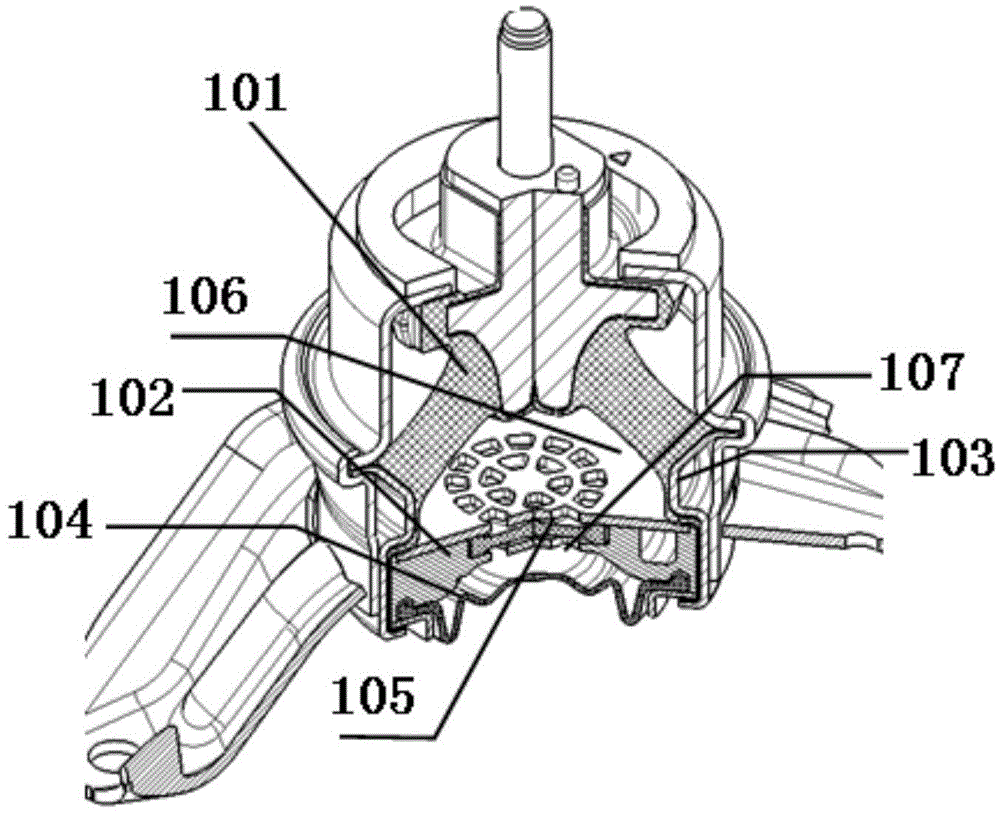

[0041] The invention provides a hydraulic mount, such as Figure 3 to Figure 7 As shown, it includes main spring 101, flow channel 102, pressure plate 108, metal skeleton 103, bottom film 104, decoupling diaphragm 105, upper liquid chamber 106 and lower liquid chamber 107; in the present invention, main spring 101, The metal skeleton 103 and the base film 104 are existing technologies without improvement, and in this application, the installation positions of each component are the same as those of the existing hydraulic mount, therefore, no detailed description will be given on these components and installation structures. description...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com