A kind of preparation method of high solid content and strong alkali resistance acrylate emulsion adhesive

A technology with acrylate and high solid content, which is applied in the field of emulsion adhesive preparation to achieve good alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

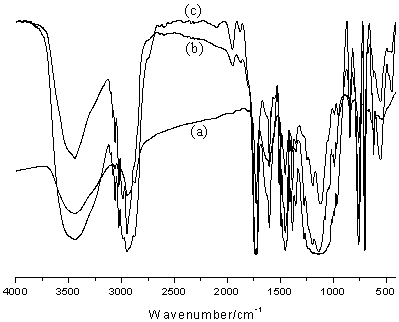

Method used

Image

Examples

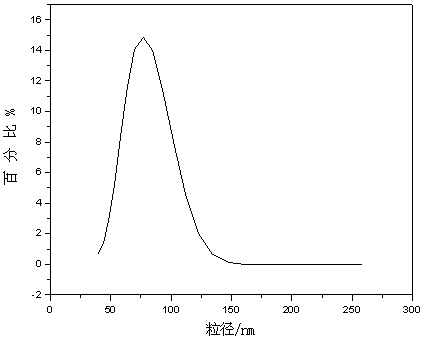

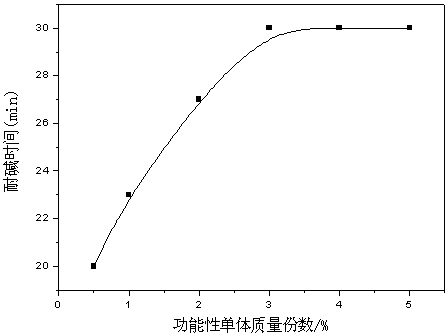

Embodiment 1

[0029] Add 230 parts of water, 1.0 parts of reactive emulsifier sodium acrylamide isopropyl sulfonate and 8.5 parts of anionic emulsifier sodium dodecylbenzene sulfonate to the In a 500ml four-necked flask with a thermometer, the temperature was raised to 70°C, and 3% oil phase was added dropwise into the four-necked flask within 20 minutes. The oil phase included 70 parts of styrene St, 25 parts of methyl methacrylate MMA, 60 parts Butyl acrylate BA, 5 parts of methacrylate MAA, 5 parts of methoxyethyl methacrylate and 0.05 part of stearyl methacrylate; then add 1 part of ammonium persulfate, and finally the remaining 97% of the oil phase Add it dropwise into a four-necked flask within 6 hours, keep warm for 1 hour, and discharge the material to obtain a functionalized acrylate emulsion with a particle size of 78.52nm, a solid content of 43%, and an alkali resistance time of 22 minutes.

Embodiment 2

[0031] Add 240 parts of water, 1.5 parts of reactive emulsifier sodium acrylamide isopropyl sulfonate and 9.5 parts of anionic emulsifier sodium dodecylbenzenesulfonate to the In a 500ml four-necked flask with a thermometer, the temperature was raised to 80°C, and 3% of the oil phase was added dropwise to the four-necked flask within 20 minutes. The oil phase included 75 parts of styrene St, 30 parts of methyl methacrylate MMA, 65 parts Parts of butyl acrylate BA, 6 parts of methacrylate MAA, 5 parts of acetoacetoxyethyl methacrylate and 0.05 part of stearyl methacrylate; then add 1.8 parts of potassium persulfate, and finally the remaining 97% The oil phase was added dropwise into the four-neck flask within 6 hours, and discharged after 1 hour of heat preservation. A functionalized acrylate emulsion with a particle size of 79.00nm, a solid content of 45.32%, and an alkali-resistant time of 28 minutes can be obtained.

Embodiment 3

[0033]Add 270 parts of water, 1.5 parts of reactive emulsifier 2-acrylamido-2-methylpropane sulfonate and 8.5 parts of anionic emulsifier sodium dodecylbenzene sulfonate directly to the In a 500ml four-necked flask with a stirrer, a condenser and a thermometer, heat up to 80°C, add 3% of the oil phase to the four-necked flask dropwise within 20 minutes. The oil phase includes 73 parts of styrene St, 30 parts of methyl methacrylate ester MMA, 62 parts of butyl acrylate BA, 5.8 parts of methacrylate MAA, 5 parts of acetoacetoxyethyl methacrylate and 0.01 part of trimethylolpropane trimethacrylate; then add 1.0 parts of sodium persulfate , and finally the remaining 97% of the oil phase was dropped into the four-necked flask within 6 hours, and the material was discharged after 1 hour of insulation. A functionalized acrylate emulsion with a particle size of 80.00nm, a solid content of 42%, and an alkali resistance time of 25 minutes can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com