A sewage sludge separator

A sewage sludge and separator technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of reducing sludge and sewage treatment rate, surrounding environmental pollution, purchasing To solve the problem of high cost, achieve the effect of simple structure, reduce labor cost and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will make a clear and complete description of the sewage sludge separator of the present invention in conjunction with the accompanying drawings.

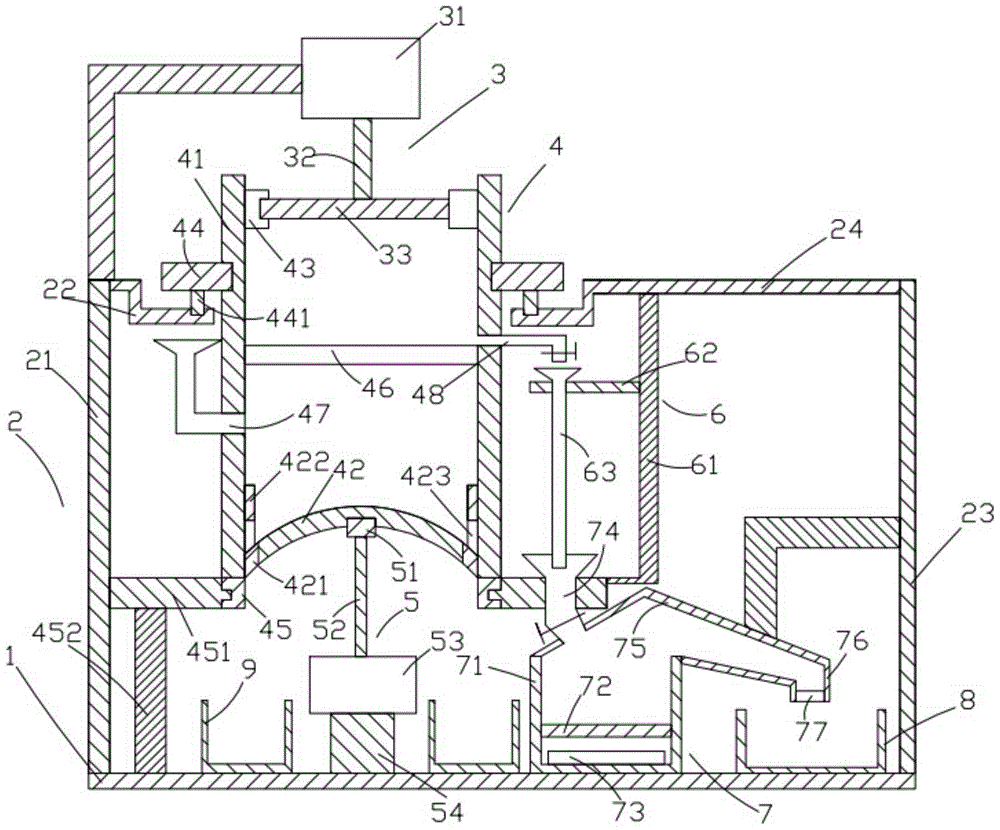

[0019] Such as figure 1 As shown, the sewage sludge separator of the present invention includes a base 1, a support device 2 located above the base 1, a rotating device 3 located above the support device 2, a frame device 4 located below the rotating device 3, The cylinder device 5 located below the frame device 4, the recovery device 6 located on the right side of the frame device 4, the heating device 7 located below the recovery device 6, the sewage recovery device located on the right side of the heating device 7 box 8 and the sludge recovery box 9 located on the left side of the heating device 7 .

[0020] Such as figure 1 As shown, the base 1 is in the shape of a cuboid, and the base 1 is placed horizontally. The support device 2 includes a first support column 21, a first support column 22 on the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com