A Diesel Engine Remote Control Monorail Conveyor

A diesel engine and single-track technology, applied in mechanical conveyors, transportation and packaging, conveyor control devices, etc., can solve problems such as low technical level, high labor intensity, and unreasonable regional layout, so as to ensure transportation safety and reduce labor costs. Strength and reduction in wire laying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

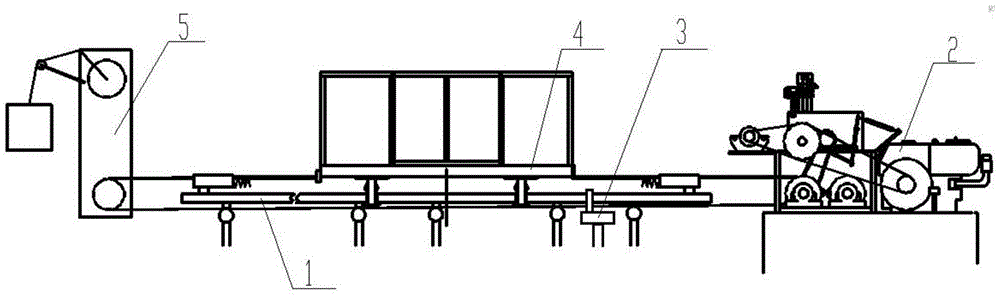

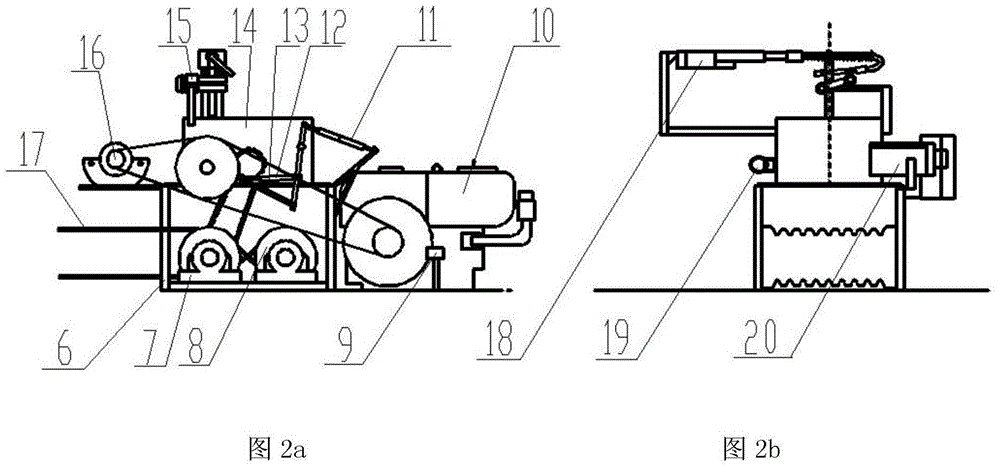

[0029] Such as figure 1 As shown, a diesel engine remote-controlled single-track conveyor includes a diesel engine remote-controlled single-track conveyor host 2, a trailer 4, a control box, and a track 1. A diesel engine 10, a clutch brake electronic control device, and a shifting device 15 are arranged on the frame of the host 2. Throttle control device 19, gearbox 14, storage battery charging device 16, wheel pair driving device.

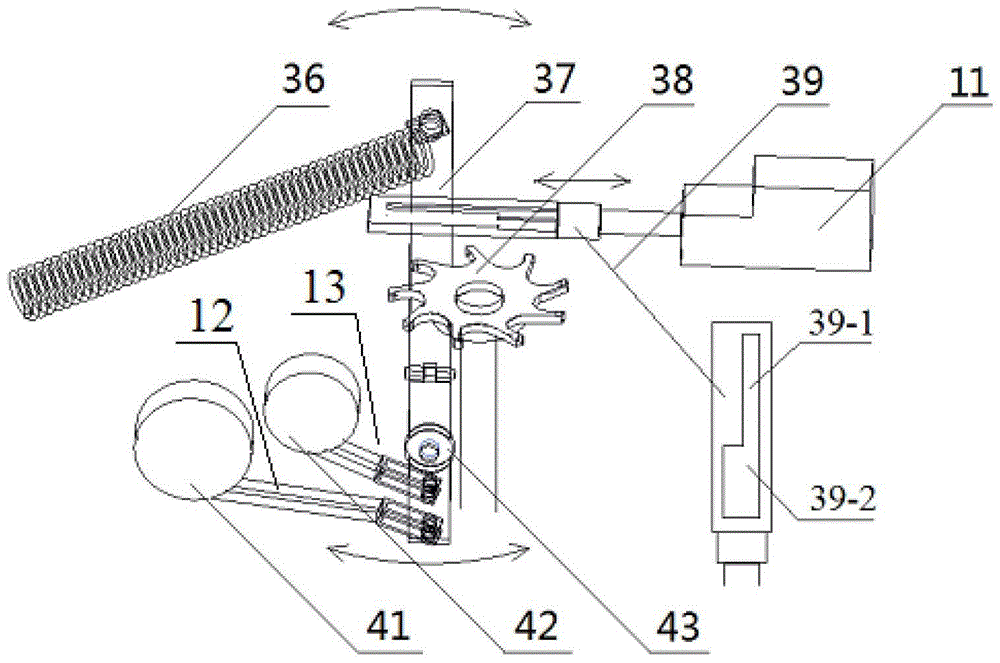

[0030] Such as image 3 As shown, the clutch brake electronic control device includes a clutch brake link 37, an L-shaped hole mechanism 39, one end of the clutch brake link 37 is connected with a clutch mechanism 41 and a brake belt mechanism 42, and the other end of the clutch brake link 37 is a spring 36 and a brake spring 36. Connected and located in the L-shaped hole of the L-shaped hole mechanism 39, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com