A non-inflatable hollow tire

A hollow tire, non-inflation technology, applied in non-pneumatic tires, tire parts, transportation and packaging, etc., to achieve strong working stability, simple structure, scientific and reasonable, and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

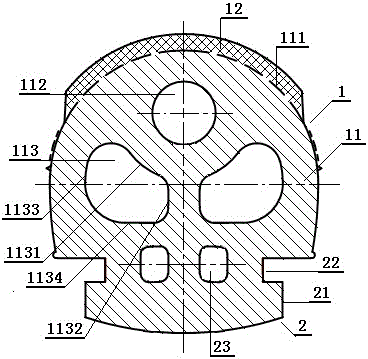

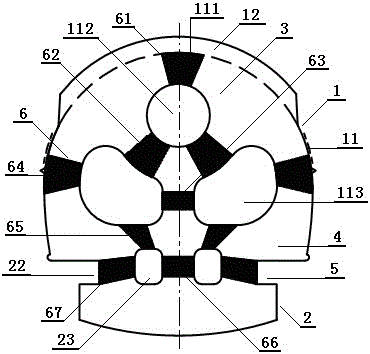

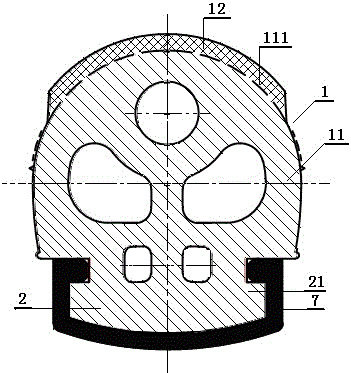

[0019] exist Figure 1-Figure 3 Among them, the main body of the non-pneumatic hollow tire of the present invention is composed of a crown 1 and a toe 2 interconnected as a whole, and is characterized in that the crown 1 includes a carcass 11 and a wear-resistant layer 12 provided with an anti-skid pattern, which is wear-resistant The layer 12 covers the top pressure bearing surface 111 on the outer surface of the carcass 11, and the toe 2 is provided with an embedded clip 21, wherein: the inside of the carcass 11 is set on the side close to the top pressure bearing surface 111 There is a circular buffer air cavity 112, and a pair of upper oblique arc-shaped cavity walls 1131, inner vertical cavity walls 1132, outer arc-shaped cavity walls 1133 and lower parts are arranged symmetrically on the other side of the carcass 11 near the middle. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com