High-speed vegetable cutter

A cutting machine, high-speed technology, applied in metal processing and other directions, can solve the problems of unstable vegetable product quality, low overall work efficiency, and consumption of a certain amount of time, so as to improve cutting efficiency, improve cutting effect, and reduce water consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

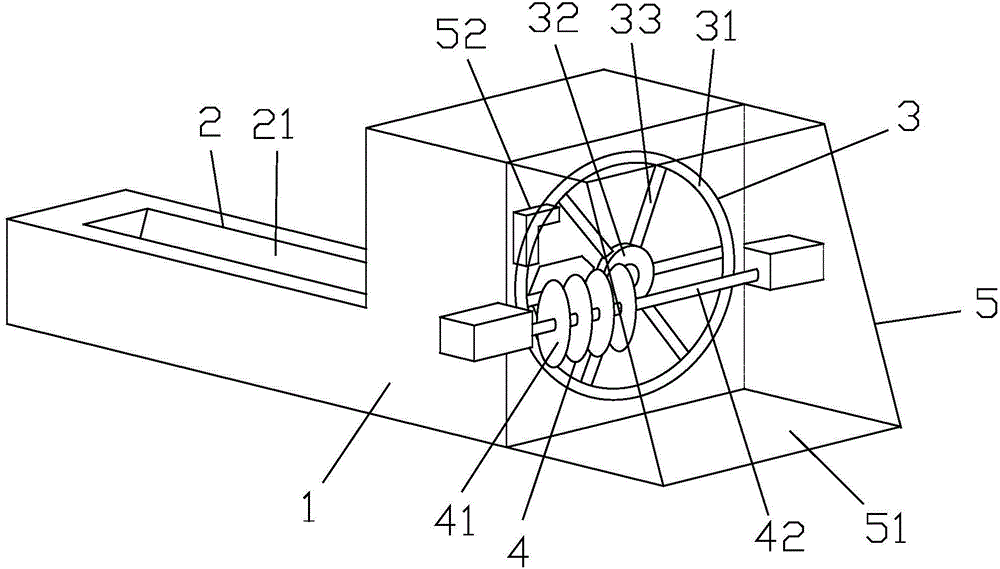

[0021] Vegetable high-speed section cutting machine of the present invention, as figure 1 As shown, a frame 1 is included, and a feeding device 2 , a longitudinal cutting device 3 and a cross cutting device 4 are installed on the frame 1 .

[0022] The feeding device 2 is a conveyor belt 21, two of which are arranged in parallel, and an included angle is arranged between the two conveyor belts 21 to form a V-shaped conveying channel.

[0023] The slitting device 3 includes a mounting ring 31 and a mounting shaft 32, the mounting shaft 32 is rotatably mounted on the frame 1, and is driven by a servo motor installed on the frame 1, and the mounting ring 31 is slidably installed in the frame 1. In the ring groove, the installation shaft 32 is coaxial with the installation ring 31 , and a cutter 33 is radially installed between the installation shaft 32 and the installation ring 31 . The cutter 33 is installed obliquely, and a plurality of cutters 33 are evenly arranged in the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com