High-precision Curvature Regulating Mechanism of Mechanical Track Seat

A track seat, high-precision technology, applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problem that the surface of the mechanical track seat is difficult to keep straight, one surface is slightly convex and the second surface is concave , the ratio of height to length is small, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

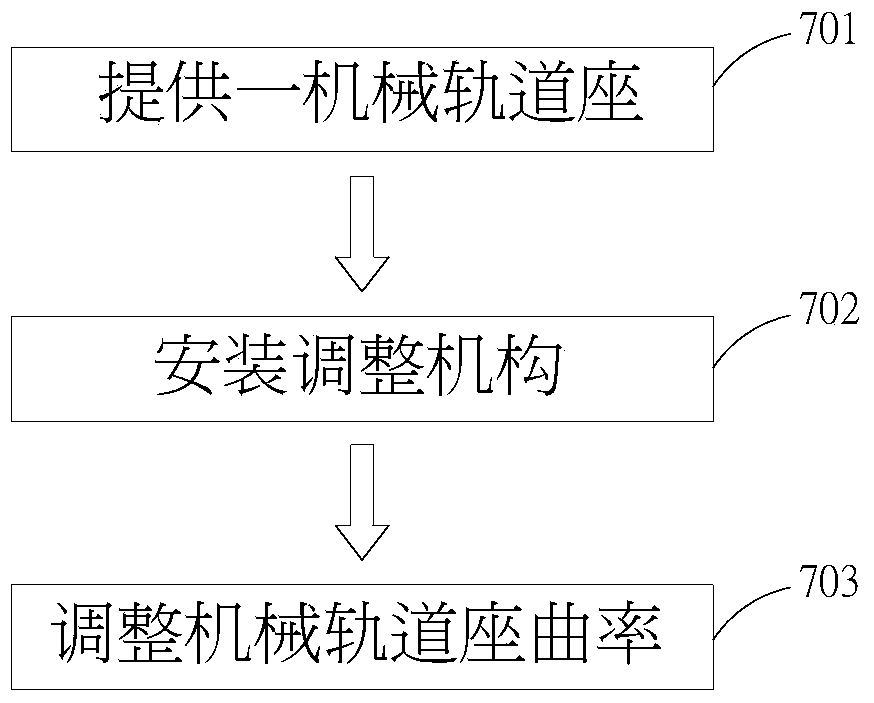

[0087] A preferred embodiment of the high-precision curvature control method of the mechanical track seat of the present invention is as follows figure 2 and Figure 3 to Figure 6B As shown, wherein, the control method includes the following steps:

[0088] (a). Provide a mechanical track base 901: the mechanical track base 20 has a housing portion 21 inserted between the two ends along the axial direction, the housing portion 21 is not located on the central axis of the mechanical track base 20, the mechanical Two ends of the track seat 20 are formed with a receiving groove 22 at the opening of the receiving part 21;

[0089] (b). Install the adjustment mechanism 902: install an adjustment mechanism 30 in the accommodation part 21 and the accommodation groove 22. The adjustment mechanism 30 includes a control rod 31, two clamping pieces 32 and two adjustment controls 33. The rod 31 can be a long column, a rectangular column, a polygonal column or a sheet-like column. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com