Contact type inter-plate welding line surplus height measuring device

A technology of weld excess height and measuring device, which is applied in electromagnetic measuring device, electromagnetic/magnetic thickness measurement, welding equipment and other directions, can solve the problems of large data reading error and low measuring efficiency, achieve high accuracy and improve measuring accuracy , the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

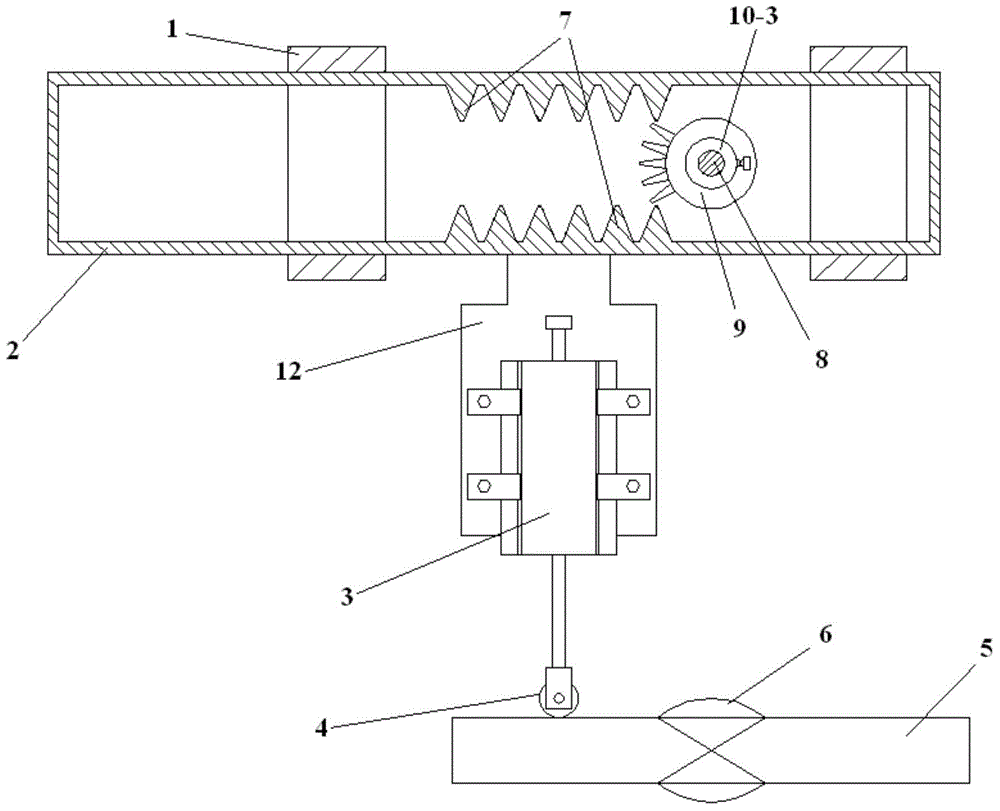

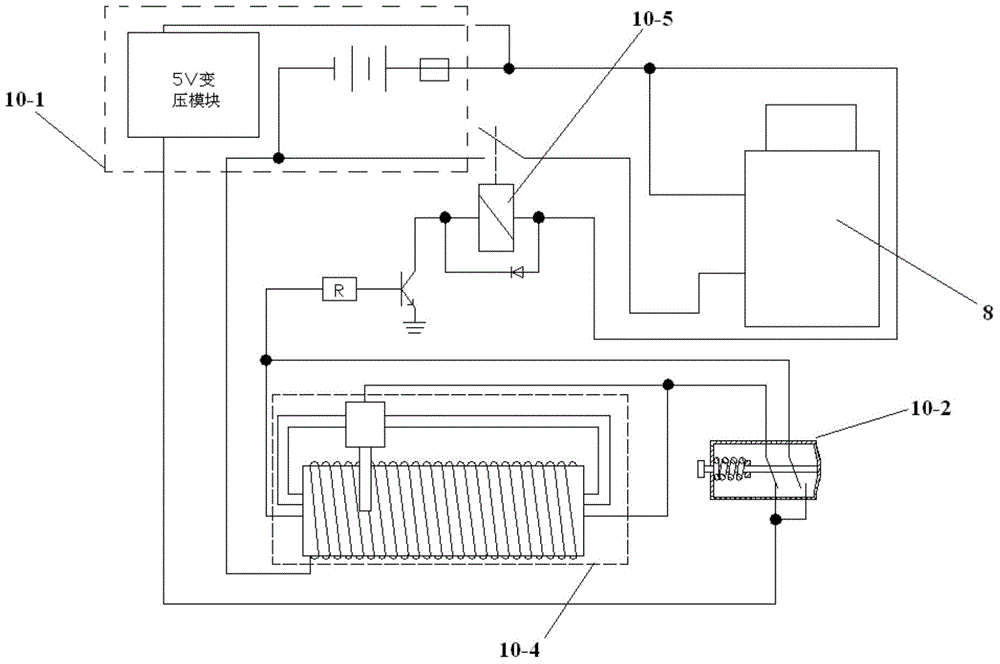

[0050] Comply with the above technical solutions, such as Figure 1 to Figure 6 As shown, this embodiment provides a contact type inter-plate weld reinforcement measuring device, which includes a guide sleeve 1, and a moving guide cylinder 2 that can move along the guide sleeve 1 is installed in the guide sleeve 1, and the moving guide cylinder 2 A displacement sensor 3 is fixedly installed on the top, and the end of the displacement sensor 3 is equipped with a roller 4 in contact with the workpiece 5. The roller 4 moves along the surface of the workpiece 5 under the drive of the moving guide cylinder 2, and the roller 4 touches the weld on the workpiece 5. When the seam surface is raised 6, the height of the roller 4 changes, and the reinforcement of the weld surface 6 is converted into the change of the output signal of the displacement sensor 3, and the inter-plate weld reinforcement is obtained according to the change of the output signal of the displacement sensor 3 .

...

Embodiment 2

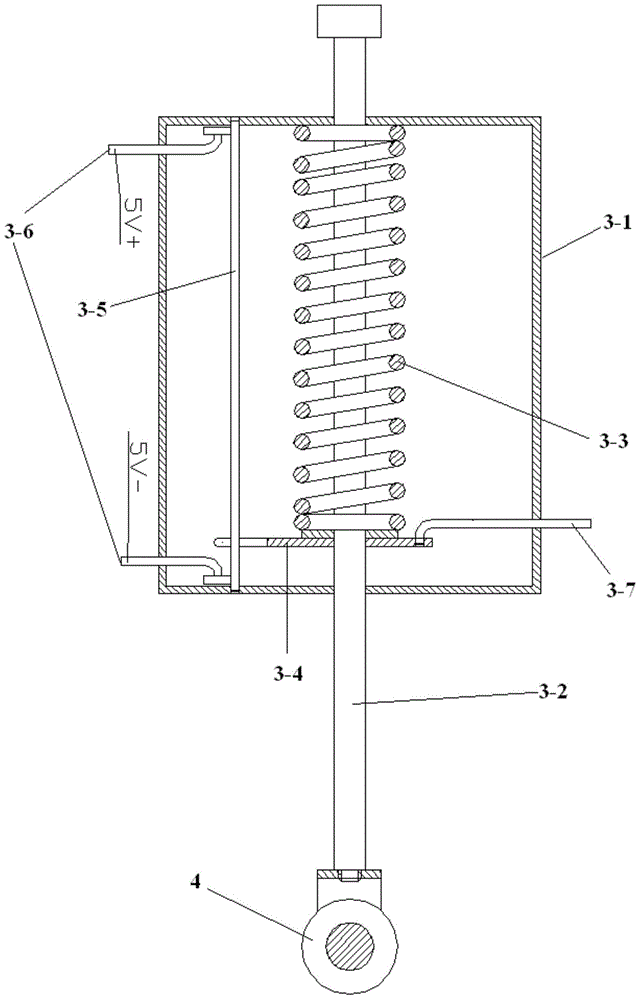

[0074] Comply with the above technical solutions, such as figure 2 As shown, the present embodiment provides a displacement sensor, which includes an insulated sensor housing 3-1, and inserts a sensor penetrating through both ends of the sensor housing 3-1 from the outside of the sensor housing 3-1. Ejector 3-2 for -1 movement;

[0075]The push rod 3-2 in the sensor housing 3-1 is covered with a compression spring 3-3, one end of the compression spring 3-3 is pushed against the inner wall of one end of the sensor housing 3-1, and the other end of the compression spring 3-3 Stand on the conductive slide 3-4 fixed on the ejector rod 3-2;

[0076] A metal rod 3-5 is fixedly installed in the sensor housing 3-1 parallel to the ejector rod 3-2, and the sliding plate 3-4 can slide relatively when in contact with the metal rod 3-5;

[0077] The input terminal 3-6 at both ends of the metal rod 3-5 is loaded with a reference voltage, and the slide piece 3-4 is connected with an outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com