Mop dehydration device

A dehydration device and mop technology, which is applied in the direction of cleaning carpets, floors, cleaning equipment, etc., can solve the problems affecting the drying degree of the mop, affecting the use status of the operator, and affecting the stability of the mop, so as to facilitate cleaning, Simple structure, firm and compact clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

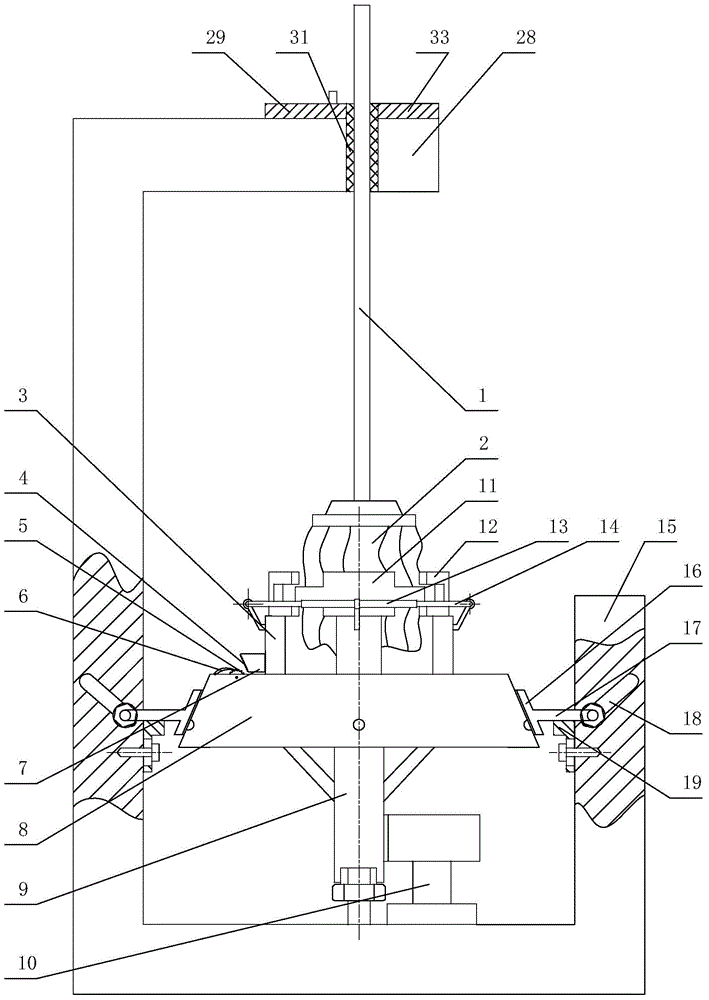

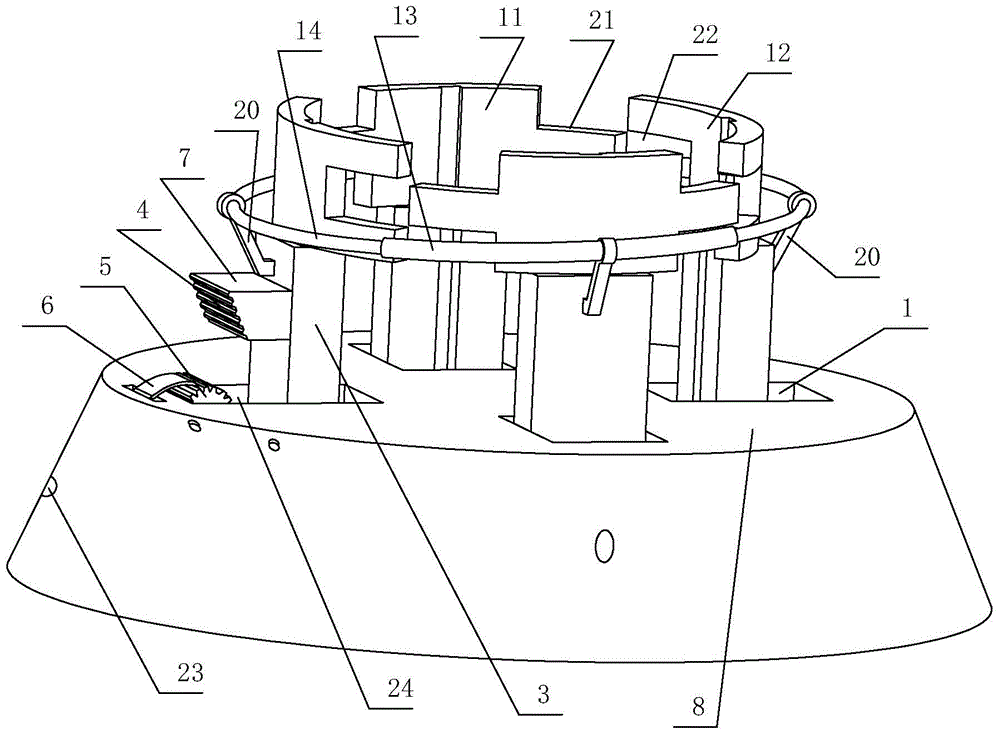

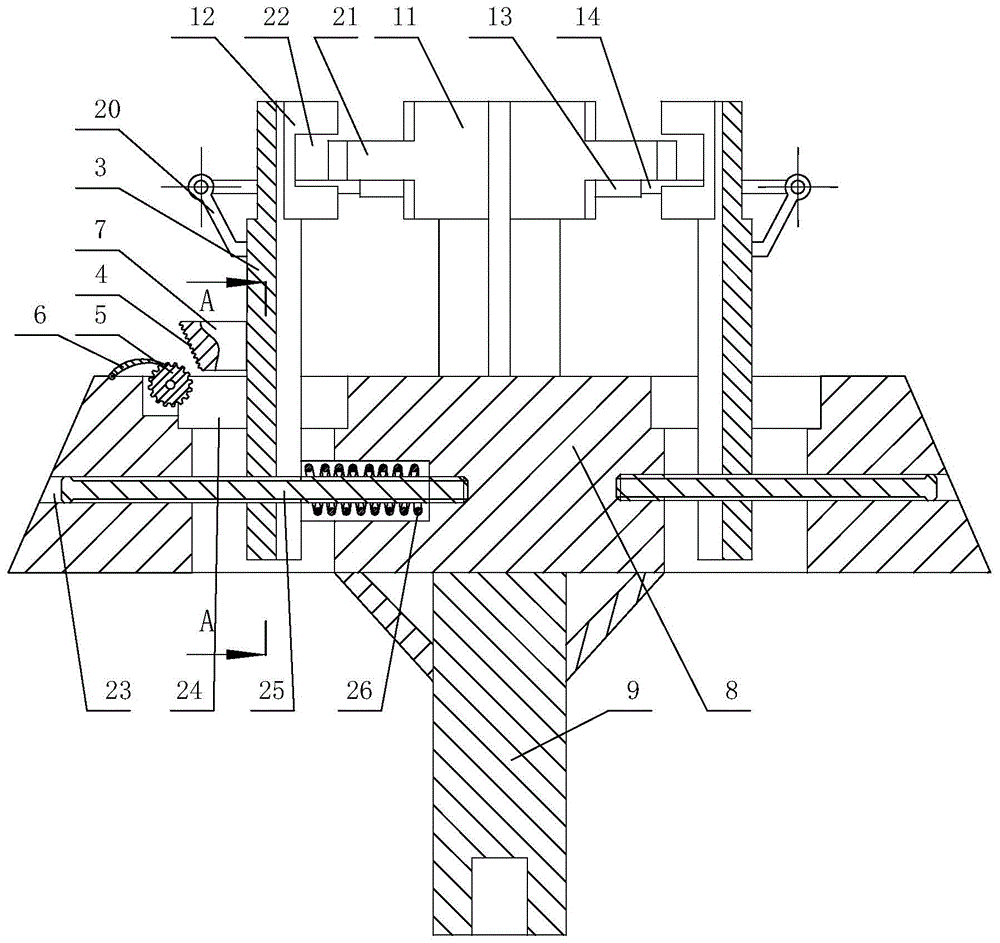

[0031] Depend on Figure 1 to Figure 7The structure schematic diagram of the mop dehydration device of the present invention shown shows that it includes a motor 10, a support base 15, a connecting base 9, a round table 8, a mop rod clamping device, a mop head clamping device and a mop head clamping drive device. The lower part of the support base 15 is U-shaped, the motor 10 is mounted on the inner bottom of the support base 15 and the output shaft of the motor 10 is connected to the lower end of the connecting support 9 through a transmission mechanism, and the upper end of the connecting support 9 is connected to the bottom of the round platform 8 Fixedly connected, the bottom of the connecting support 9 is rotationally connected with the bottom of the support base 15; Described mop head clamping drive device comprises briquetting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com