Peanut shell separator

A technology for separating machines and fruit shells, which is applied in the fields of shelling, pod removal, and food science. It can solve the problems of production personnel's health impact, difficult production, and easy failures, so as to achieve good health, less failures, and avoid dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

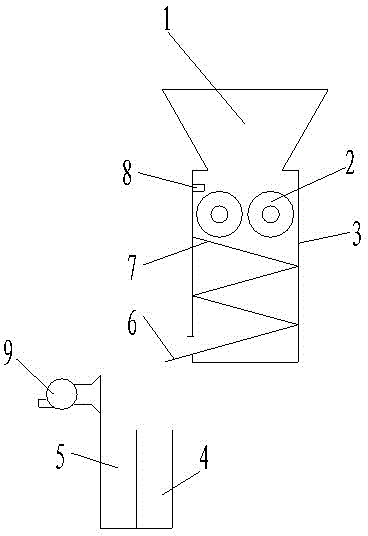

[0013] like figure 1 The peanut husk separator shown is characterized in that it includes a cylinder body 3, a feed inlet 1 is provided on the top side of the cylinder body 3, and two shell crushing rollers 2 arranged side by side are located below the feed inlet 1. , a water spray head 8 is arranged between the crushed shell roller 2 and the feed port 1,

[0014] A downwardly inclined discharge plate 7 is arranged below the shell crushing roller 2, and a fruit shell collection bucket 4 and a peanut collection bucket 5 are installed below the end of the discharge plate 7 protruding from the cylinder 3, The husk collection barrel 4 protrudes from one end of the barrel 3 near the discharge plate 7,

[0015] A blower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com