Microalgae composite living bait for shellfish breeding and production method of microalgae composite living bait

A production method and technology of microalgae, applied in the field of microalgae composite living bait, can solve the problems of unstable culture environment, easy to be polluted, low degree of industrialization, etc., to improve growth rate and quality, avoid nutrient loss, and reduce morbidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

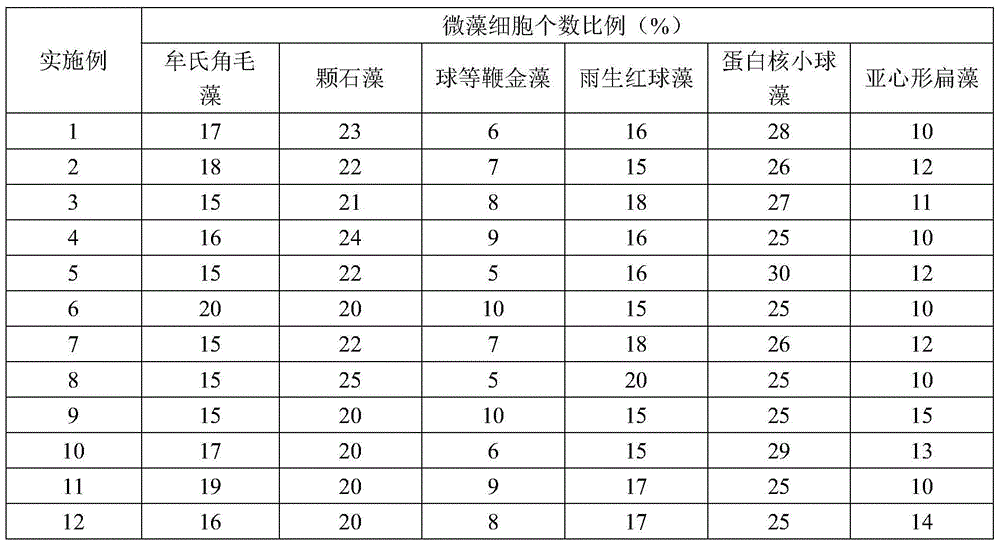

[0023] (1) According to the nutritional requirements of Pacific oyster seedlings (eye-spot larvae stage), Chaetoceros mouvii, Coccolithophora, Isoflagellates, Haematococcus pluvialis, Chlorella pyrenoidosa and subcardioid planus were selected. Algae are species of microalgae.

[0024] (2) Using a photobioreactor (ZL201220434882.9) to cultivate the microalgae selected in step (1) to obtain a microalgae liquid. Among them, the culture temperature of Chaetoceros mouchii, Coccolithophora, Isoflagellates, Haematococcus pluvialis and P. 4 cells / mL, and the culture media were f / 2, NMB3, f / 2, BBM and Comvitamin; 4 cells / mL, and the medium was BG11 medium. After being cultured in a photobioreactor, the density of 1.0×10 9 (Chaetoceros moowii), 2.7×10 10 (coccolithophores), 1.5×10 10 (Isochrysis globosa), 6.8×10 9 (Haematococcus Pluvialls), 5.0×10 10 (Chlorella pyrenoidosa), 9.2×10 9 (Subcordiform Algae) cells / mL of microalgae liquid.

[0025] (3) The microalgae liquid obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com