Arrangement for a fuel injection system with a fuel injection valve and a decoupling element

A technology of fuel injection valves and components, applied in the field of decoupling components, to achieve the effects of improving vibration damping, reducing noise transmission, and high noise damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

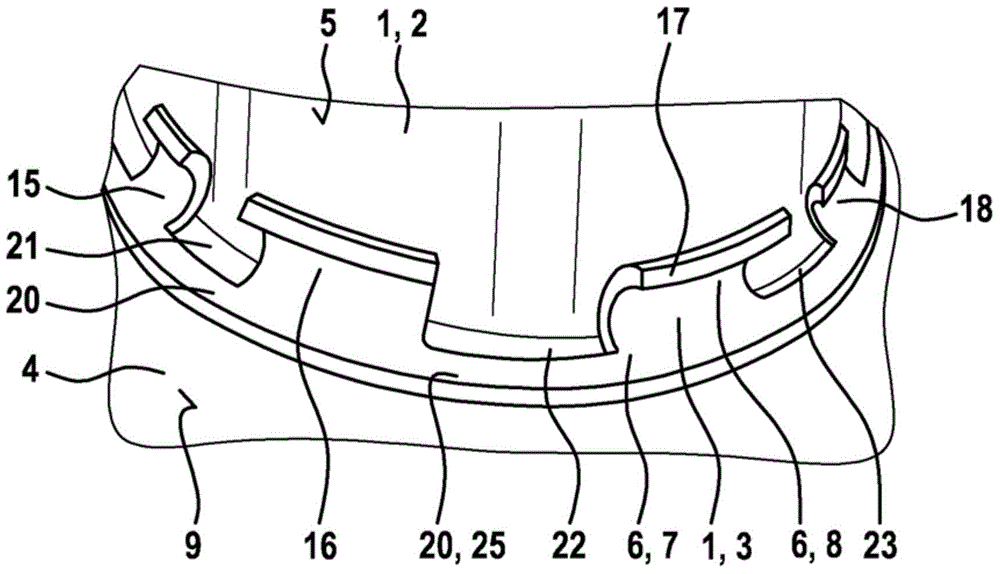

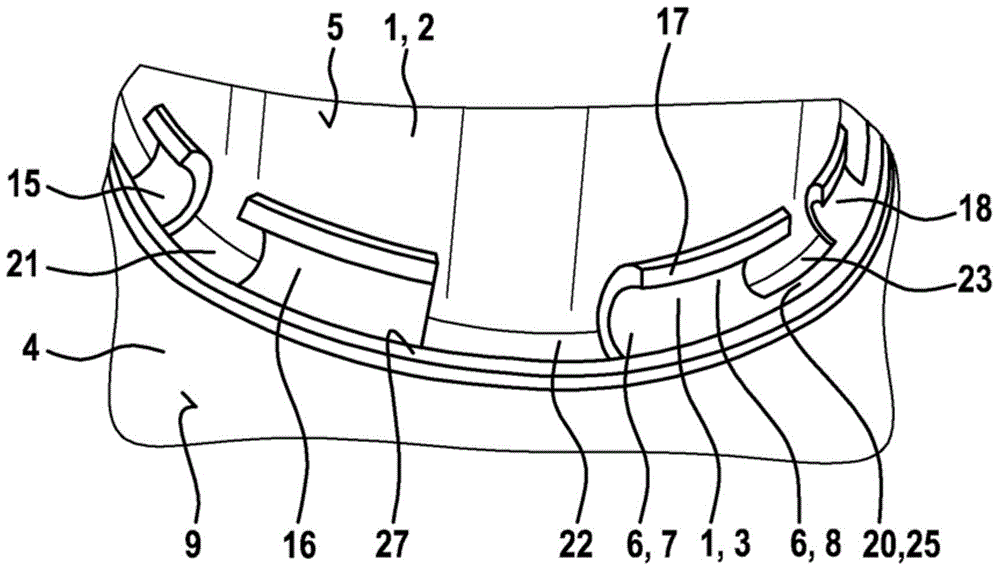

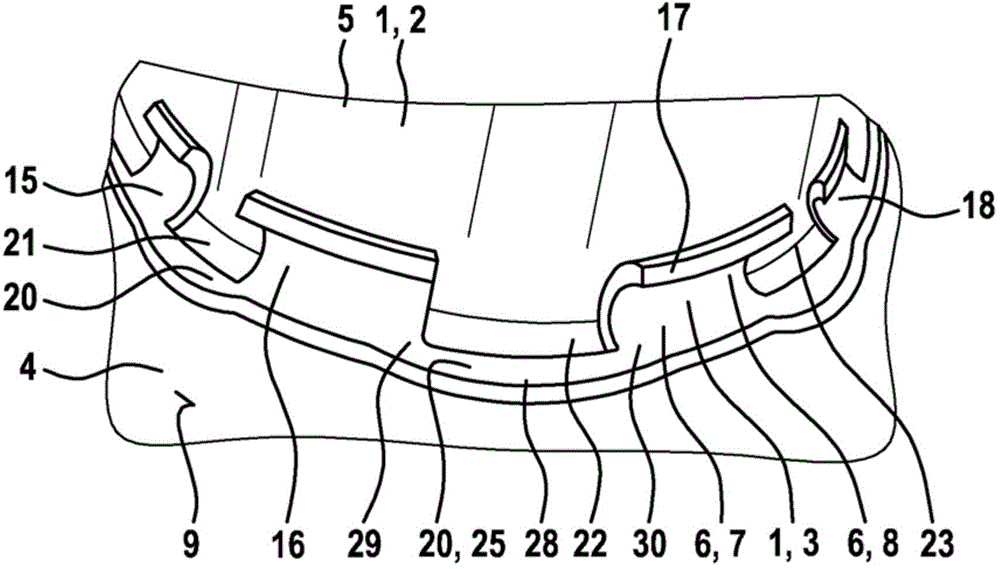

[0027] figure 1 Arrangement 1 with fuel injection valve 2 and decoupling element 3 and cylinder head 4 according to the first exemplary embodiment of the invention are shown in a simplified, schematic and three-dimensional illustration. The arrangement 1 is for a fuel injection system of an internal combustion engine. The arrangement 1 is particularly suitable here for a fuel injection system for injecting fuel directly into a combustion chamber of an internal combustion engine. The internal combustion engine can be designed in particular as a mixture-compressing, spark-ignition internal combustion engine, gasoline or other fuels suitable for such internal combustion engines and suitable mixtures thereof being injected.

[0028] The decoupling element 3 is particularly suitable for this application.

[0029]The transmission of noise from fuel injection valve 2 to cylinder head 4 can be reduced by arranging assembly 1 or decoupling device 3 . Fuel injector 2 is designed, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com