Anti-shielding metal cable gland and assembly shielding sealing method

A metal cable and fixed head technology, applied in the direction of cable terminals, etc., can solve the problems of product performance not reaching, dust or water entering the box, and cables not passing through normally, so as to avoid product slippage, easy operation, time saving and labor saving , the effect of preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

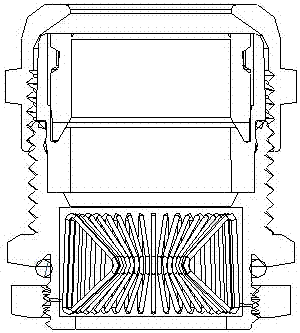

[0024] Embodiment 1: with reference to attached Figure 1-16 . An anti-shielding metal cable fixing head, comprising a hex nut 8, a first O-ring 7, a main body 6, an inner part 3, a waterproof ring 2 and a tight nut 1, and one side of the mouth of the waterproof ring 2 is provided with a layer of sealing The film 22 of the waterproof ring is designed as an annular groove structure 21 and cooperates with the boss 33 on the inner part; the inside of the main body 6 is equipped with a triangular spring 5; the arc boss 31 on the inner part 3 and the main body 6 The inner arc groove 61 fits; the second O-ring 4 is added between the inner fitting 3 and the main body 6. The bottom 2 of the waterproof ring is made into a bevel 23 and matches the bevel in the interior part 3. Both sides 51 of the triangular spring 5 are inclined planes and the contact position between the triangular spring and the cable is designed as an arc shape 52 . A boss 32 is provided axially on the inner fitt...

Embodiment 2

[0025]Embodiment 2: On the basis of Embodiment 1, an assembly, shielding and sealing method of an anti-shielding metal cable gland includes a hexagonal nut 8, a first O-ring 7, a main body 6, an inner fitting 3, a waterproof ring 2 and a forced Tighten the nut 1, and make a groove 21 on the outside of the waterproof ring 2 to cooperate with the ring-opening discontinuous boss 33 on the inner part 3. When assembling, the annular discontinuous boss 33 on the inner part 3 snaps into the groove 21 on the waterproof ring , to prevent the cable from being pushed out of the main body when the cable passes through the waterproof ring; the annular arc boss 31 on the inner fitting 3 cooperates with the inner arc groove 61 of the main body. When the inner fitting is installed in the main body, the inner fitting 3 The cooperation between the annular arc boss 31 and the inner arc groove 61 of the main body can prevent the inner fittings from falling off and reduce repeated installation duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com