Cable laying and displacing frame

A technology of cables and cables, applied in cable laying equipment, optical fiber/cable installation, etc., can solve the problems of low work efficiency, labor consumption, poor construction effect, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

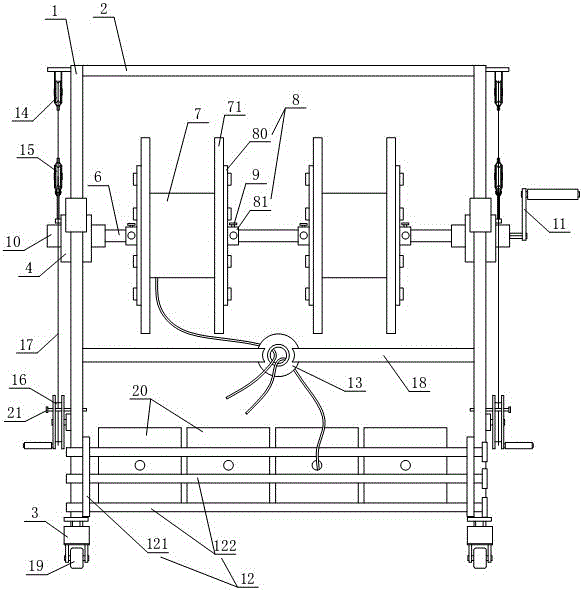

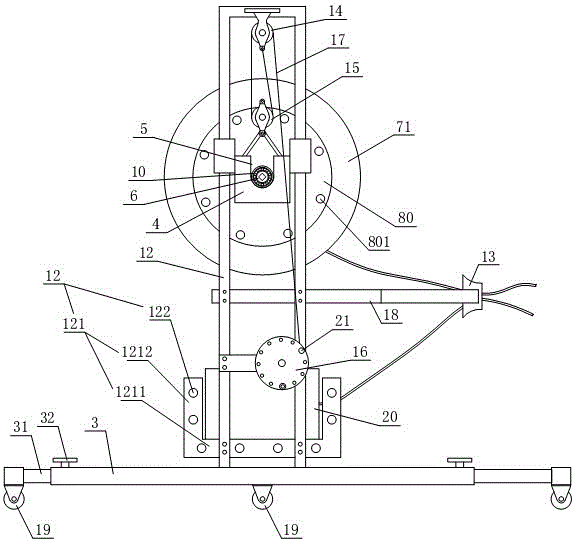

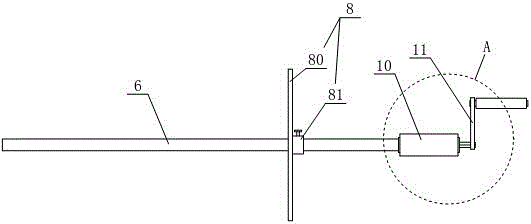

[0024] Referring to the accompanying drawings, the cable laying rack includes two brackets 1 arranged vertically and at intervals from left to right and a crossbeam 2 connected to the top of the two brackets 1. The bottom ends of the two brackets 1 are vertically fixed to each other and extend along the front and rear directions. A strip-shaped base 3, a support block 4 is vertically slidably installed on each of the two supports 1, and the two support blocks 4 are correspondingly arranged and are respectively driven and positioned by the handwheel driving mechanism arranged on the respective supports 1, the two support blocks 4 The top end is provided with a groove 5, a rotating shaft 6 is arranged between the two grooves 5, and at least two fixed wheel discs 8 that can be connected with the wire retaining discs 71 on both sides of the winding roller 7 are slidably sleeved on the rotating shaft 6 and The fixed wheel disc 8 can be positioned on the rotating shaft 6 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com