Lead access mechanism for stator winding

A stator winding and stator technology, applied in connection, circuit/collector parts, measuring devices, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the goal of improving production efficiency, reducing labor force and improving working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

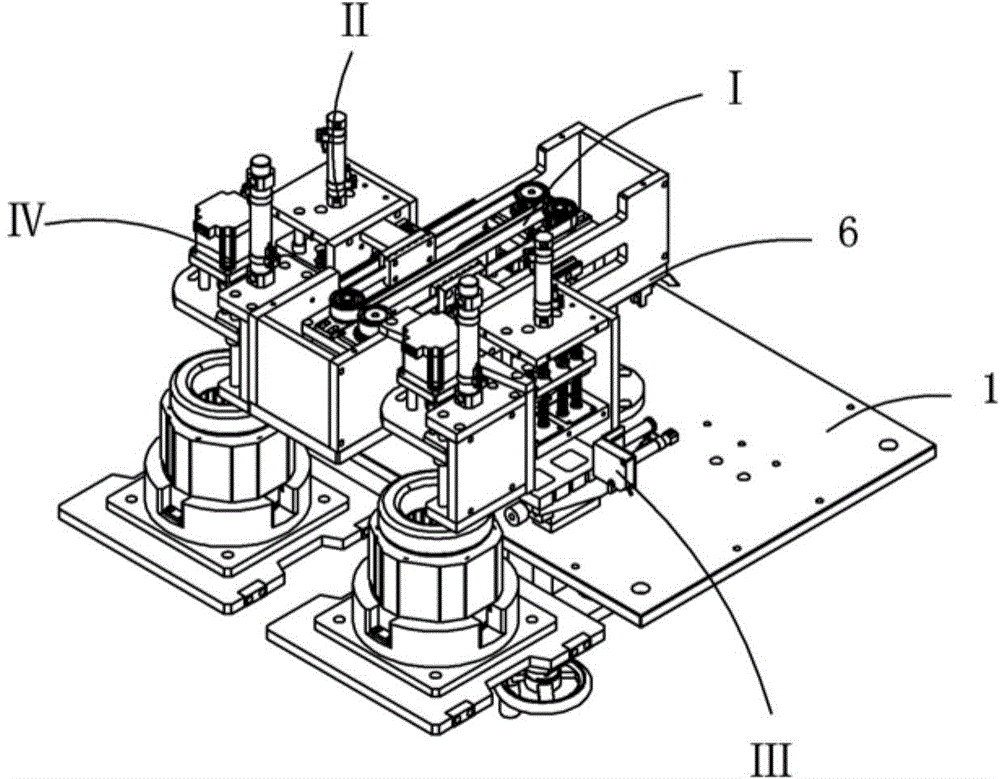

[0034] Examples, see attached Figure 1-12 , a stator winding lead wire access mechanism, which includes a base plate 1, a screw nut 2 is installed on the base plate, a screw rod 3 is installed on the screw nut, and the upper and lower parts of the screw rod pass through the screw rod support 4 respectively Support, the lower end of the screw rod is connected with a hand wheel 5, the upper end of the screw rod is connected with a transport motor fixing plate 6, two sets of guide sleeves 7 are installed on the bottom plate, and a set of guide posts 8 are installed on each set of guide sleeves. , the upper ends of the two guide posts are connected together through the upper connecting plate, the lower ends of the two guide posts are connected together through the lower connecting plate, and the screw rods pass through the upper and lower connecting plates respectively.

[0035]Side fixing plates 9 are respectively installed on the left and right sides of the fixing plate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com