A flexible array eddy current probe and detection method for detecting conductive structure defects

A conductive structure, flexible array technology, used in measurement devices, material analysis by electromagnetic means, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

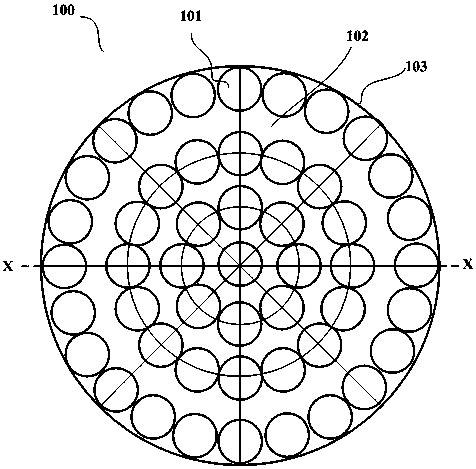

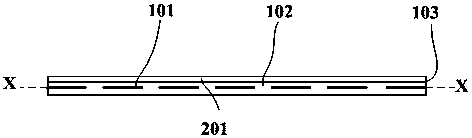

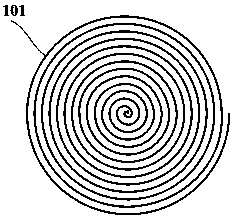

[0050] figure 1It is a top view of a flexible eddy current array probe 100 (hereinafter referred to as flexible probe or probe) provided by the present invention. The probe is provided with a plurality of coils 101 as excitation and sensing elements, and these coils 101 are grouped to form a plurality of coil assemblies ( figure 1 There are four coil assemblies in the example), so that each coil assembly contains one or more coils 101.

[0051] A large number of coils 101 are distributed on the probe in the form of a planar array, and are used to detect complex surface shape defects of conductive structures. Preferably, it is hoped that the array of coils can cover as much surface of the probe as possible, but the present invention does not exclude the implementation structure that the array of coils only covers a part of the surface of the probe.

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com