Liquid dehumidification cross-flow packed tower

A solution dehumidification and packed tower technology is applied in the field of cross-flow heat and mass transfer process, which can solve the problems of troublesome replacement of packing, large waste, inability to realize cross-flow heat and mass transfer characteristics, etc., so as to save equipment costs, improve experimental efficiency, and improve The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

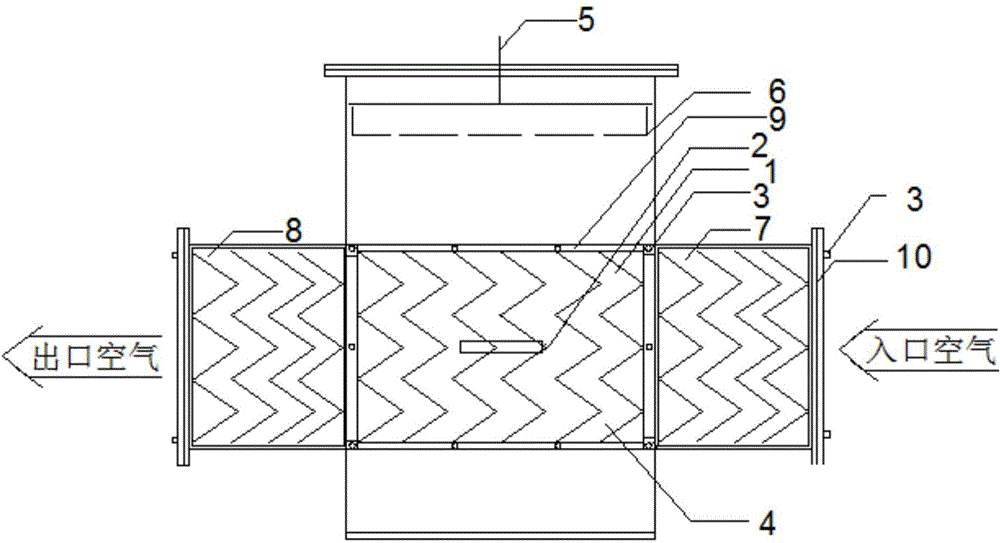

[0025] Such as figure 1 Shown is a solution dehumidification cross-flow packed tower, including a cross-shaped packed tower body, the inside of the packed tower body is a cavity structure, and the outer shell of the packed tower body is covered with a foam insulation board of about 1 cm. The cross-flow heat and mass transfer is guaranteed to be infinitely adiabatic; the top of the packed tower body is covered with a top cover, and the top cover is punched to introduce the liquid spray pipe 5, and the packed tower body below the top cover is fixed by a slot There is a liquid distribution plate 6, and the solution ejected from the liquid spray pipe 5 falls evenly after passing through the liquid distribution plate 6.

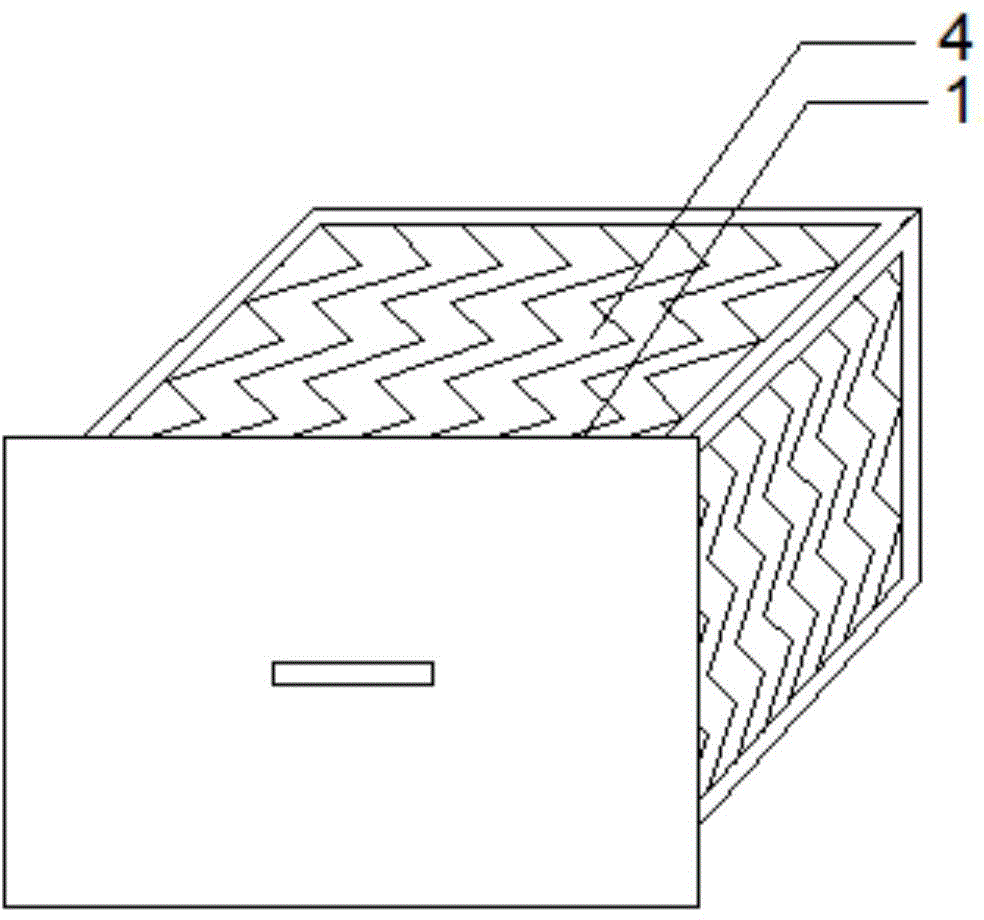

[0026] A packing chamber is arranged in the packing tower body directly below the liquid distribution plate 6, and the packing chamber is located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com