Connecting rod mutual sealing water distribution structure

A technology of water diversion structure and connecting rod, which is applied in the direction of valve details, multi-way valves, engine components, etc., can solve the problems of large operating resistance and inconvenient operation, and achieve the effect of small operating force, simple structure, and labor-saving operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

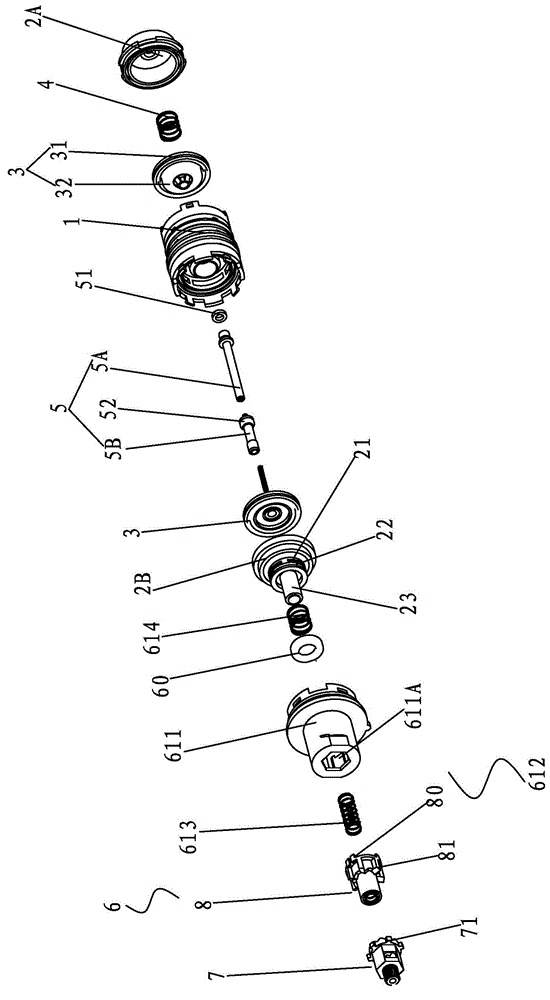

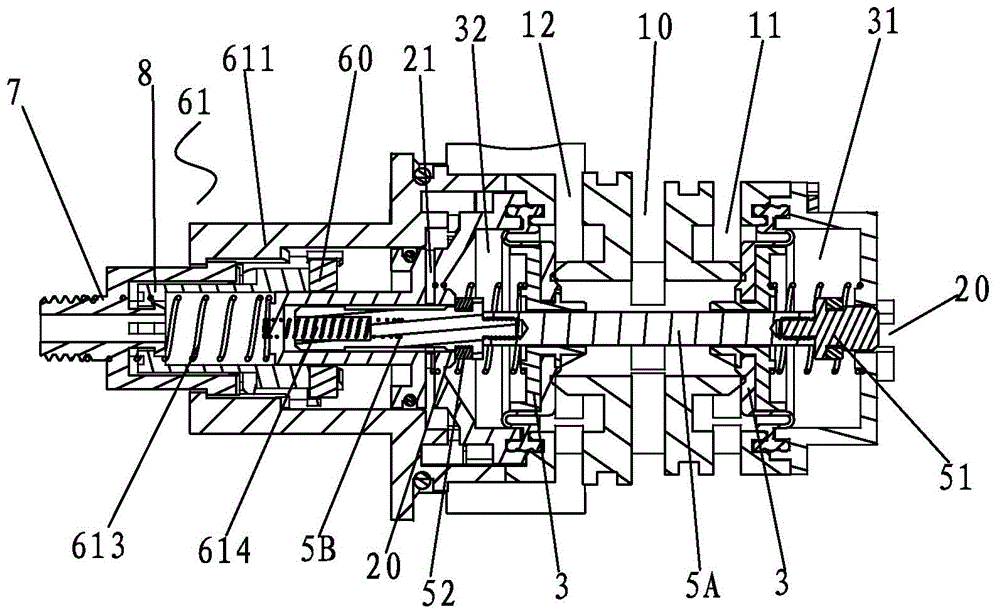

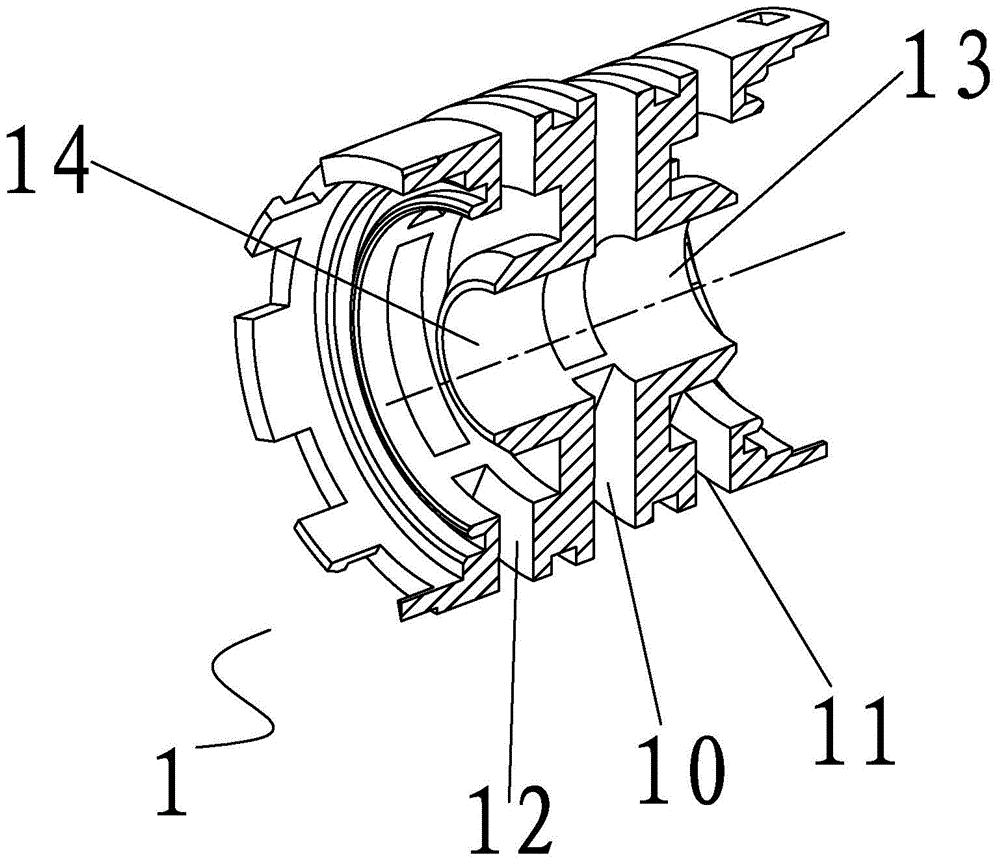

[0037] Specific implementation methods, such as Figure 1 to Figure 4 As shown, a connecting rod inter-sealing water diversion structure according to the present invention mainly includes the following components: body 1, first and second covers 2A, 2B, first and second connecting rods 5A, 5B, First and second blocking units 51, 52, at least two sealing deformation units 3, return spring 4, magnetic unit 60, housing 611, springs 613, 614, pressing unit 7 and rotating push rod 8;

[0038] When assembling, for the water-dividing structure part, first, the first and second blocking units 51 and 52 are respectively attached to the outer peripheries of the first and second linkage rods 5A and 5B; then the first and second blocking units 51 , 52 are also sleeved on the two connecting rods 5 respectively, and then the first connecting rod 5A is passed through the body 1, so that the deformation part 32 of the sealing deformation unit 3 is blocked in the water inlet channels 13, 14, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com