Hot-melt reinforced flushable fully degradable non-woven material and production method

An enhanced and fully degradable technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of low melting point of PE, high melting point of PP, and reduced dispersion, so as to improve product strength, high entanglement strength, and increase The effect of the bonding surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

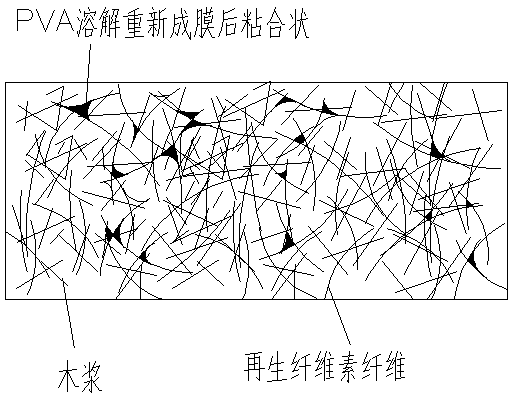

[0011] Embodiment 1: with reference to attached figure 1 and 2 . A hot-melt reinforced flushable fully degradable non-woven material, characterized by the weight percentage: PVA hot-soluble fiber is between 1%---5% and including the end value, and regenerated cellulose fiber is 1%--- Between 50% and including the end value, for wood pulp between 98%---45% and including the end value. Regenerated fiber refers to viscose fiber, tencel, bamboo fiber and other regenerated cellulose fibers.

Embodiment 2

[0012] Example 2: On the basis of Example 1, the PVA heat-soluble fiber is 5%, the regenerated fiber is 50%, and the wood pulp is 45%.

Embodiment 3

[0013] Embodiment 3: On the basis of Embodiment 1, PVA heat-soluble fiber is 1%, regenerated fiber is 1%, and wood pulp is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com