Photovoltaic cell piece series welding device and method

A photovoltaic cell and cutting device technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of easy bending of the end of the welding strip, prevent curling or bending, and improve welding efficiency and welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

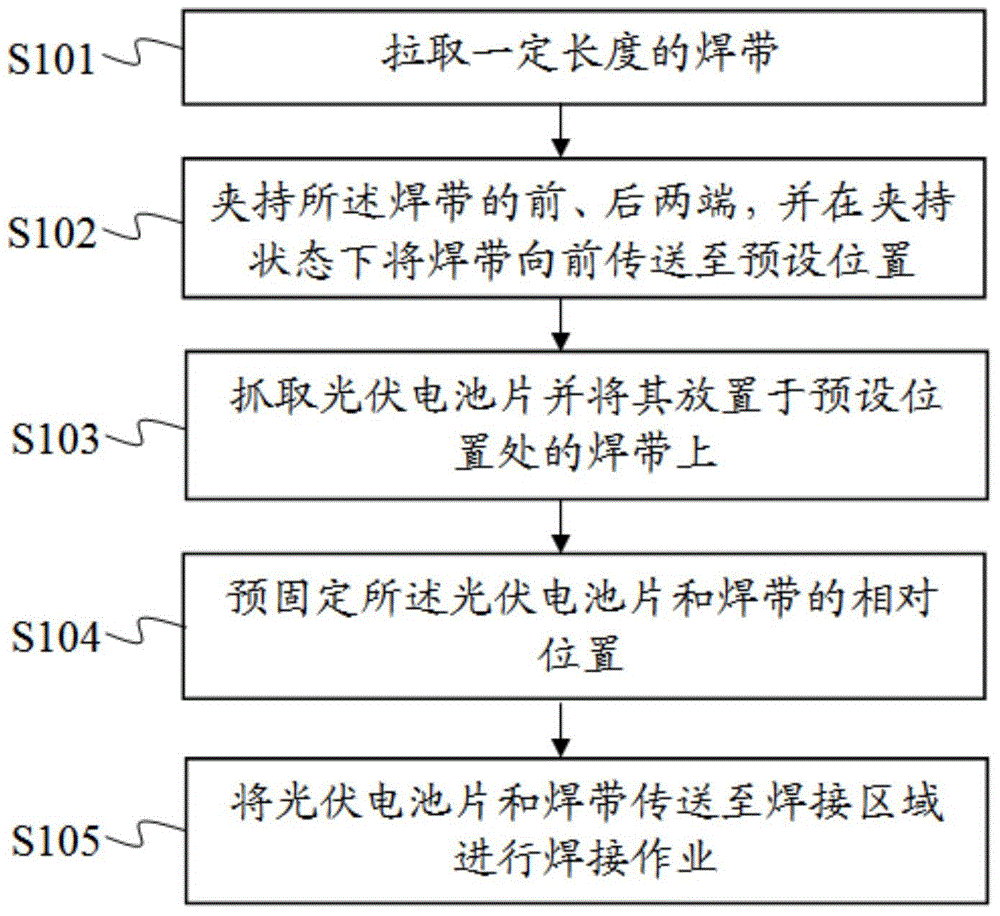

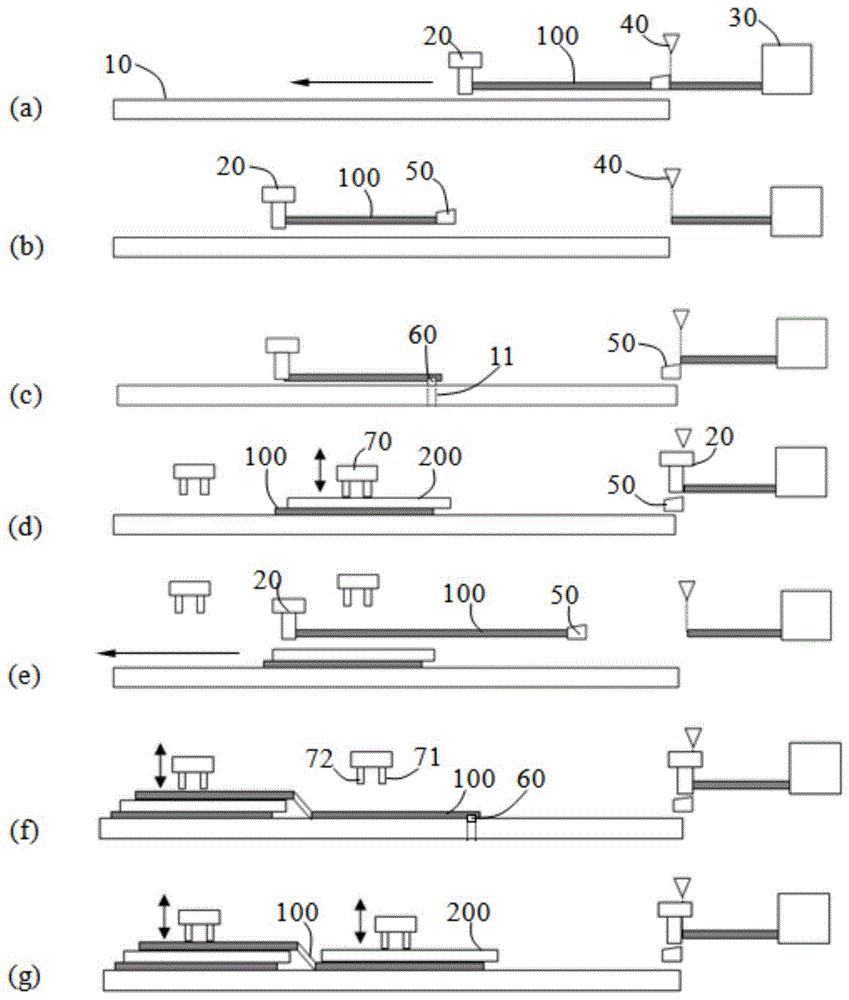

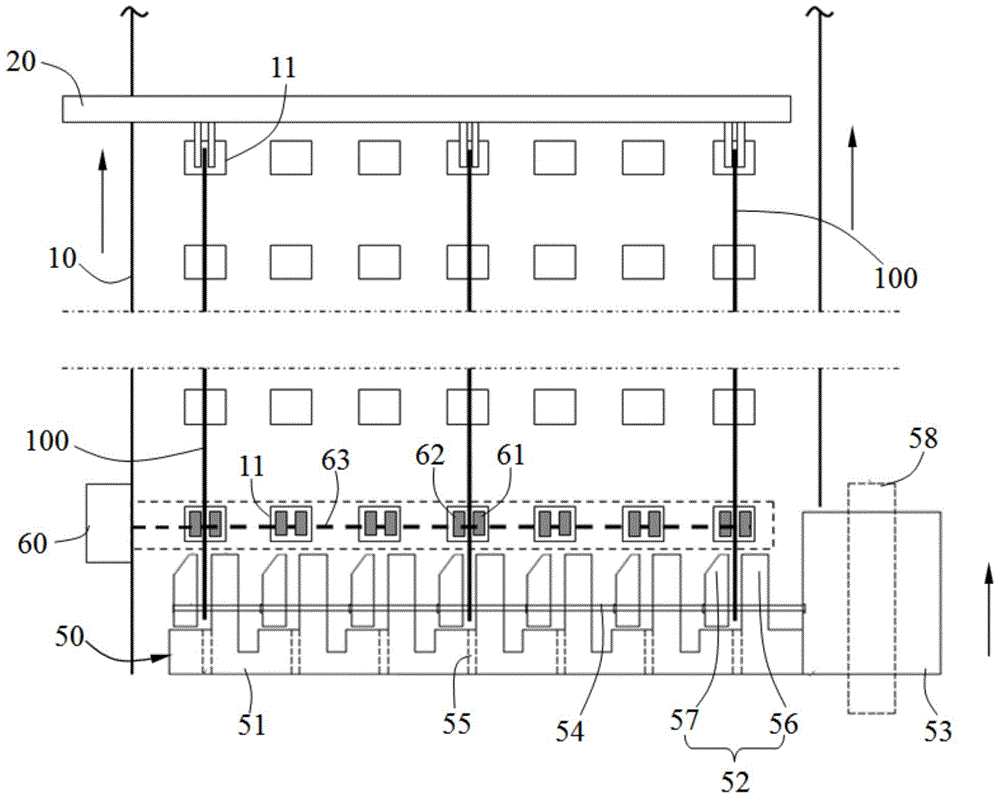

[0034] see figure 1 As shown, the present invention provides a method for stringing photovoltaic cell sheets, which is mainly applied to a photovoltaic stringer welding machine, and realizes welding ribbons to photovoltaic cell sheets by controlling the stringer welding machine. The stringer at least includes: a conveyor belt 10 , a ribbon clamp 20 , a ribbon supply device 30 and a ribbon cutter 40 , and the stringer method of the present invention will be described in conjunction with the stringer.

[0035] In the preferred embodiment of the present invention, please refer to figure 1 As shown, the string welding method may further comprise the steps:

[0036] S101: pulling a certain length of welding ribbon;

[0037] S102: clamping the front and rear ends of the welding ribbon, and forwarding the welding ribbon to a preset position under the clamping state;

[0038] S103: Grab the photovoltaic cells and place them on the welding strip at the preset position;

[0039] S10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com