Automobile seat cushion automatic welding production line and production method thereof

A technology for automatic welding and car seats, applied in welding accessories, welding equipment, welding equipment, etc., to achieve the effect of improving production efficiency and welding accuracy, improving automation level, and reducing the demand for manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

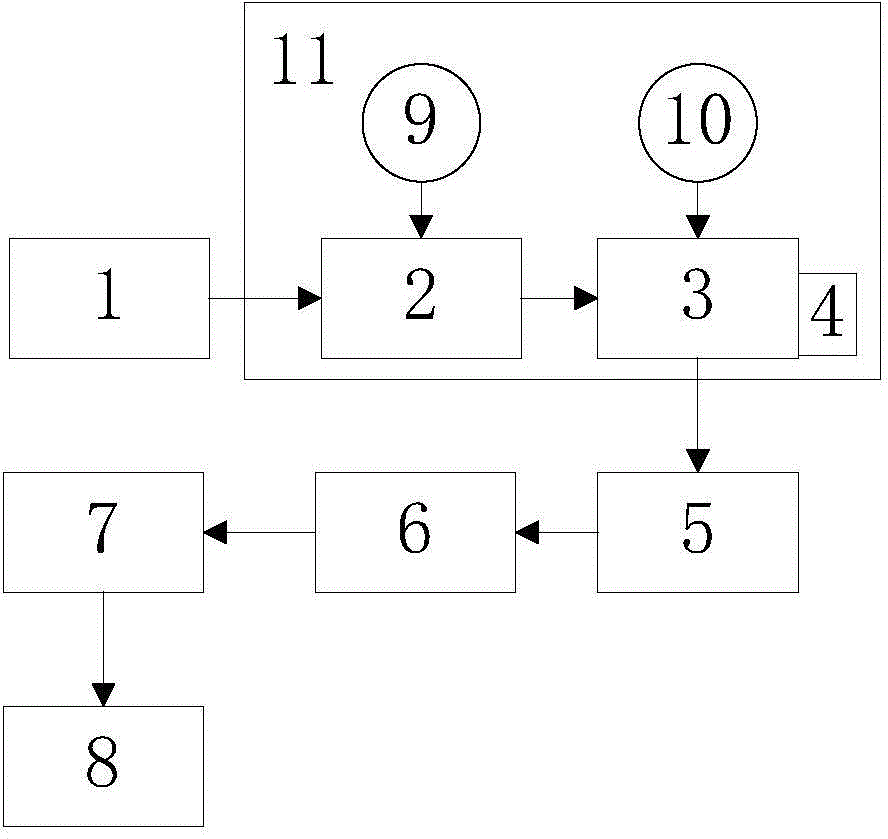

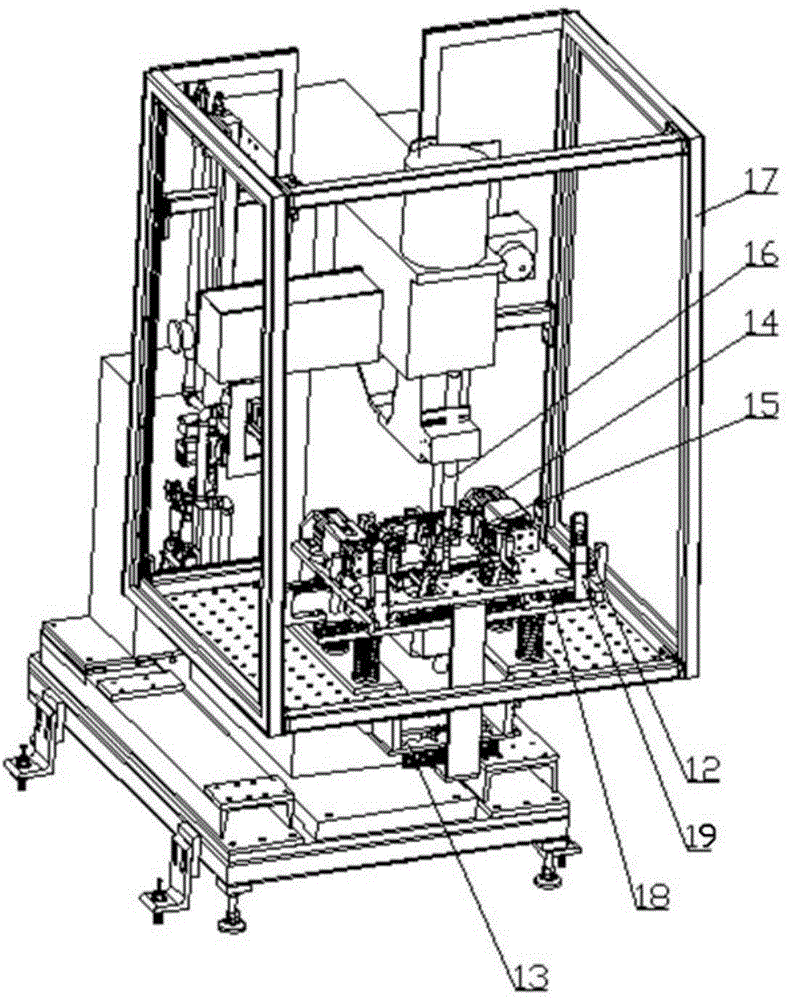

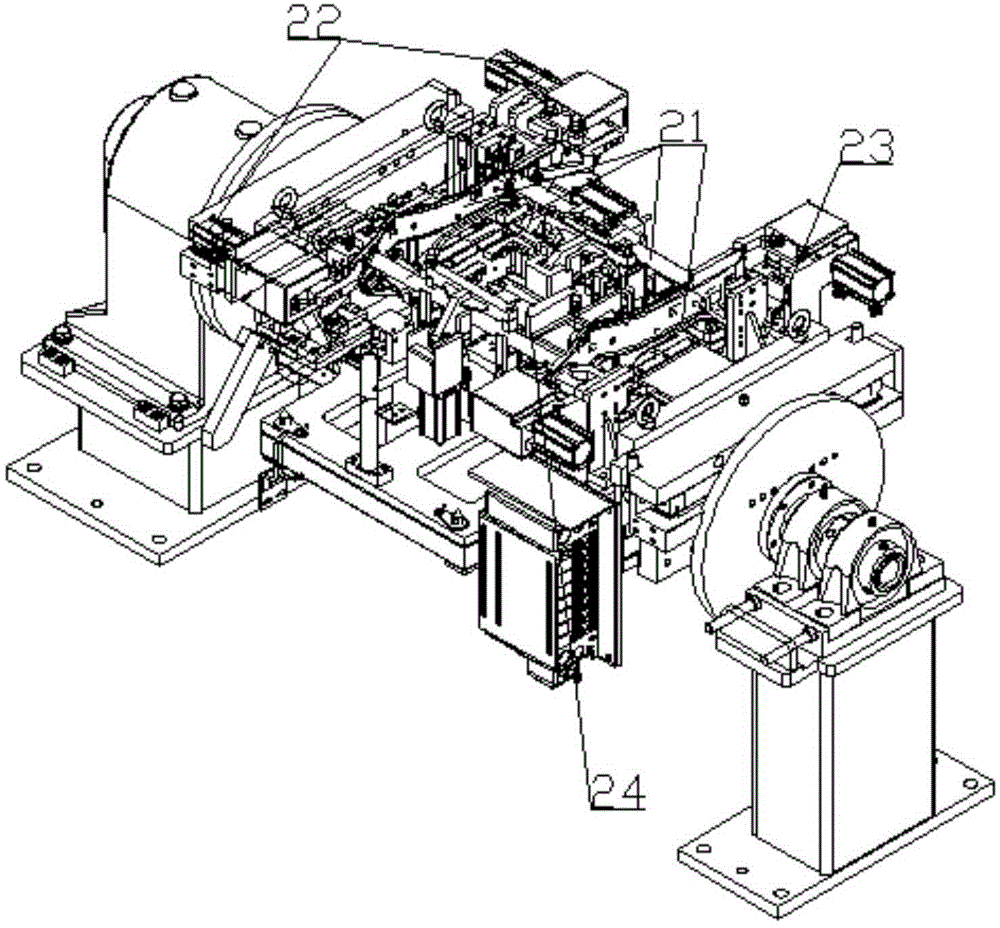

[0028] The automatic welding production line of the patented automobile seat cushion of the present invention controls two arc welding robots to cooperate with the designed fixture to fix and clamp, and the welding robot automatically welds to realize the automobile seat cushion. Only one robot workstation, two arc welding robots, eight One station and three people complete all the welding actions.

[0029] The first station mainly completes the spot welding action to realize the dash panel assembly of the car seat cushion. The second station, the third station, the fourth station and two arc welding robots form a robot workstation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com