Catenary-shaped ultrasonic longitudinal vibration horn with axial opening at the output end

A horn and output technology, applied in the field of mechanical vibration, can solve the problems of shortening the service life of the transducer, limited amplitude amplification factor, increasing cost, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

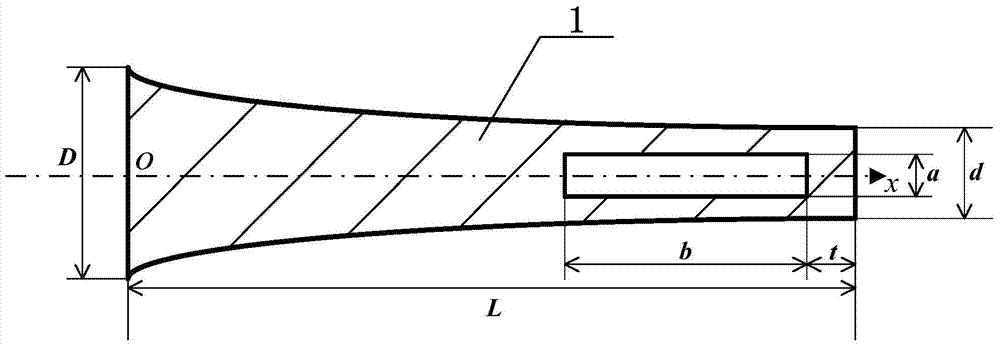

[0017] exist figure 1 Among them, the catenary-shaped ultrasonic longitudinal vibration horn with an axial opening at the output end of the present invention is composed of the horn 1 . In this example, the two ends of the horn 1 are parallel planes perpendicular to the center line, and the side is a rod-shaped body with a hyperbolic cosine rotation surface. The geometric shape of the side is a curve in the rectangular coordinate system

[0018] y=(d / 2)chγ(L-x), where

[0019] is the rotating surface formed by the generatrix and the x-axis is the rotation axis, 0≤x≤length L of the horn, where y is the radius of the cross-section at the coordinate x, and D is the diameter of the large end of the horn 1. When in use, change The large end of the horn 1 is connected to the ultrasonic transducer, d is the diameter of the small end of the horn 1, and the small end of the horn 1 is an output end. The length L of the horn in this embodiment is 120 mm, the diameter D of the large e...

Embodiment 2

[0022] In this example, the two ends of the horn 1 are parallel planes perpendicular to the center line, and the side is a rod-shaped body with a hyperbolic cosine rotation surface. The geometric shape of the side is a curve in the rectangular coordinate system

[0023] y=(d / 2)chγ(L-x), where

[0024] is the rotating surface formed by the generatrix and the x-axis is the rotation axis, 0≤x≤length L of the horn, where y is the radius of the section at the coordinate x, D is the diameter of the large end of the horn 1, and the length of the horn 1 The big end is the input and the little end is the output. The horn length L, the diameter D of the large end of the horn 1, the geometrical dimensions of the diameter d of the small end of the horn 1, and the materials used in this embodiment are the same as in Example 1. A rectangular through hole is processed at a distance of 2 mm from the small end t, the length b of the rectangular through hole is 18 mm, the length b of the rec...

Embodiment 3

[0026] In this example, the two ends of the horn 1 are parallel planes perpendicular to the center line, and the side is a rod-shaped body with a hyperbolic cosine rotation surface. The geometric shape of the side is a curve in the rectangular coordinate system

[0027] y=(d / 2)chγ(L-x), where

[0028] is the rotating surface formed by the generatrix and the x-axis is the rotation axis, 0≤x≤length L of the horn, where y is the radius of the section at the coordinate x, D is the diameter of the large end of the horn 1, and the length of the horn 1 The big end is the input and the little end is the output. The horn length L, the diameter D of the large end of the horn 1, the geometrical dimensions of the diameter d of the small end of the horn 1, and the materials used in this embodiment are the same as in Example 1. A rectangular through hole is processed at a distance of 21.6 mm from the small end t, the distance t between the outer hole wall of the rectangular through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com