Peanut harvesting device

A peanut harvesting and vibrating screen technology, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of high labor intensity, low work efficiency, and complex structure, so as to reduce labor intensity and improve work efficiency , The effect of simple transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

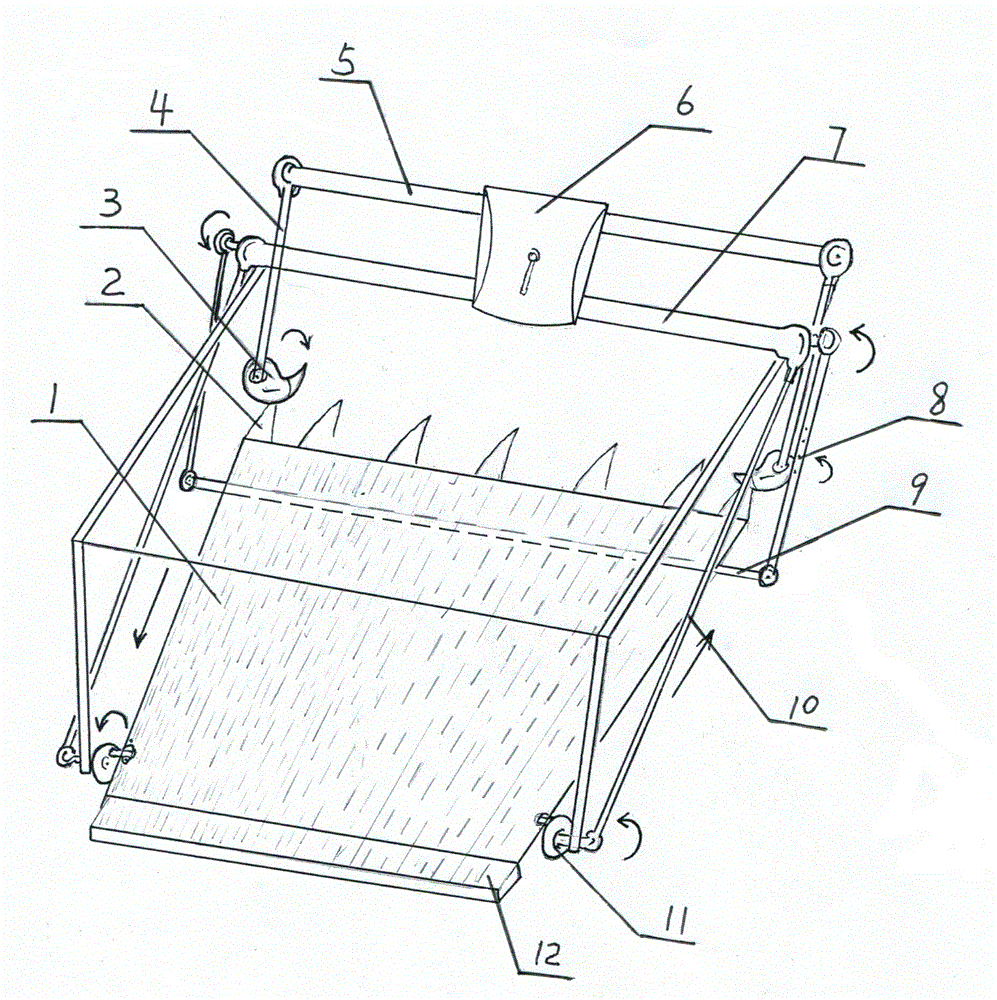

[0012] refer to figure 1 , a peanut harvesting device, comprising a frame, a vibrating screen 1 is provided at the bottom of the frame, and a harvesting knife row 2 is provided at the front end of the vibrating screen 1; The gearbox 6 is equipped with two front output shafts 5 and rear output shafts 7 with opposite rotation directions in parallel on the gearbox 6, and two oppositely moving soil plows 3 are arranged on the frame on both sides in front of the vibrating screen 1 , the soil squeezing plow 3 includes a plow body, the front end of the plow body is connected with a plow point, and the plow point is movably connected to the plow body, so that when encountering resistance exceeding its own load, the plow point can be bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com