Water-containing thickened oil PVT experiment method

An experimental method and heavy oil technology, applied in the direction of weighing, measuring devices, instruments, etc. by removing certain components, can solve the problems of high water content and high water content that cannot be analyzed experimentally, and achieve small and uniform density difference stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1. A water-containing heavy oil PVT experimental method comprises the following steps:

[0045] Step 1: Sample Preparation

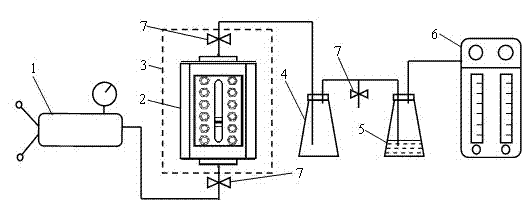

[0046] like figure 1 shown. For shallow water-bearing heavy oil samples, at the sampling temperature, pressurize the water-bearing formation heavy oil samples to the formation pressure where the water-bearing formation heavy oil samples were taken at the time of sampling, and shake them well until the pressure no longer drops. At this time, the sample saturation process After completion, a single-phase formation fluid sample is formed; the single-phase fluid sample is transferred into a PVT analysis container; the above-mentioned single-phase formation fluid sample is transferred into a PVT analysis container;

[0047] The sample preparation is completed in the PVT analysis container 2, and the PVT analysis container 2 is placed in the heat preservation device. The inlet and outlet of the PVT analysis container 2 are provided with valve...

Embodiment 2

[0076] Example 2. A water-containing heavy oil PVT experimental method comprises the following steps:

[0077] Step 1: Sample Preparation

[0078] like figure 1 shown. For the water-bearing heavy oil samples in the middle and deep formations, at 100°C, pressurize the water-bearing formation heavy oil samples to the formation pressure where the water-bearing formation heavy oil samples were taken when sampling, and shake them well until the pressure no longer drops. At this time, the sample saturation process After completion, a single-phase formation fluid sample is formed; the single-phase fluid sample is transferred into a PVT analysis container; the above-mentioned single-phase formation fluid sample is transferred into a PVT analysis container;

[0079] The sample preparation is completed in the PVT analysis container 2, and the PVT analysis container 2 is placed in the heat preservation device. The inlet and outlet of the PVT analysis container 2 are provided with valv...

Embodiment 3

[0111] Example 3. A water-containing heavy oil PVT experimental method comprises the following steps:

[0112] Step 1: Sample Preparation

[0113] like figure 1 shown. At the formation temperature where the sample was taken (according to the formation temperature measured at the time of sampling), pressurize the heavy oil sample from the water-bearing formation to the formation pressure where the heavy oil sample from the water-bearing formation was taken when sampling, and shake it well until the pressure no longer drops , when the sample saturation process is completed, a single-phase formation fluid sample is formed; the single-phase formation fluid sample is transferred into the PVT analysis container; the above-mentioned single-phase formation fluid sample is transferred into the PVT analysis container;

[0114] The sample preparation is completed in the PVT analysis container 2, and the PVT analysis container 2 is placed in the heat preservation device. The inlet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com