Intelligent oil pumping control method and intelligent oil pumping unit

An intelligent control and pumping unit technology, applied in earthwork drilling, mechanical equipment, machines/engines, etc., can solve problems such as inability to automatically adjust the balance, the inability to automatically adjust the stroke times, and the mismatch between the stroke times and the oil production of the oil well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

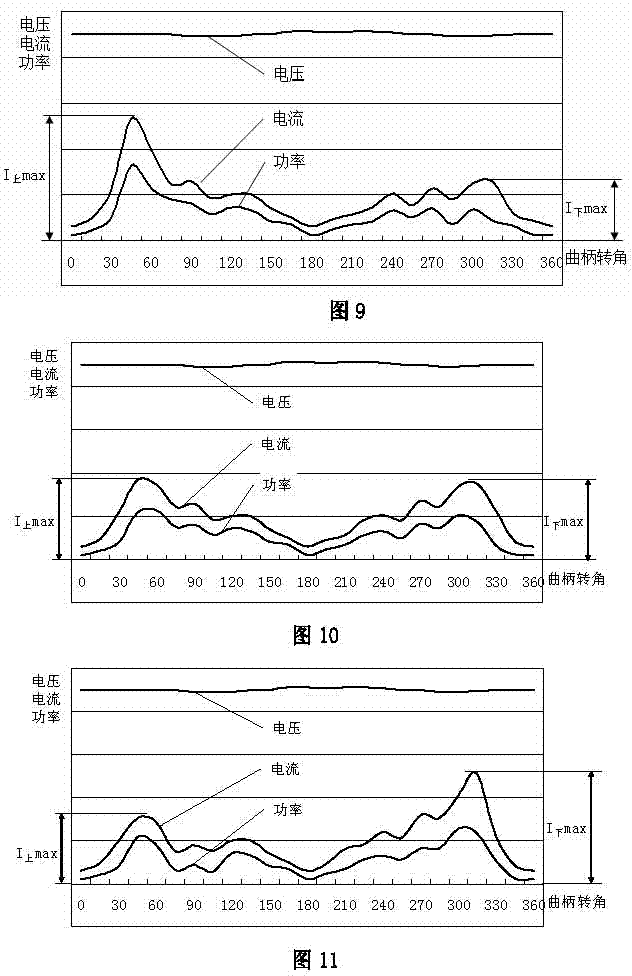

[0046] Embodiment 1, as attached Figure 6 , 7 , shown in 8, this intelligent control oil pumping method comprises intelligent pumping unit, and this intelligent pumping unit comprises main motor 15, beam 3, balance boom 7, crank 9 and rope suspension device 1; A balance boom 7 is fixedly installed on the left end, and a mobile counterweight box 28 and a driving device capable of moving the mobile counterweight box 28 left and right are respectively installed on the balance boom 7, and a central processing unit and a three-phase electrical parameter acquisition device are also included. The three-phase electric parameter acquisition device is installed on the power supply input end; a frequency converter is installed between the main motor 15 and the power supply input end, and a load sensor 17 is fixedly installed on the rope hanger 1 for collecting the suspension point load value F. A stroke process measuring device is installed on the intelligent pumping unit to collect...

Embodiment 2

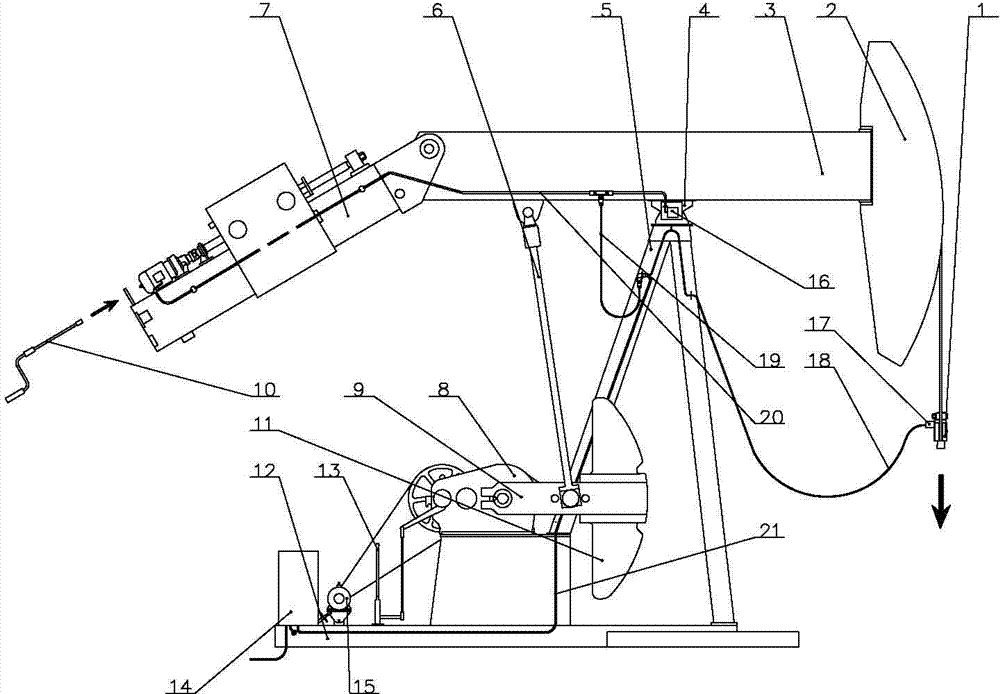

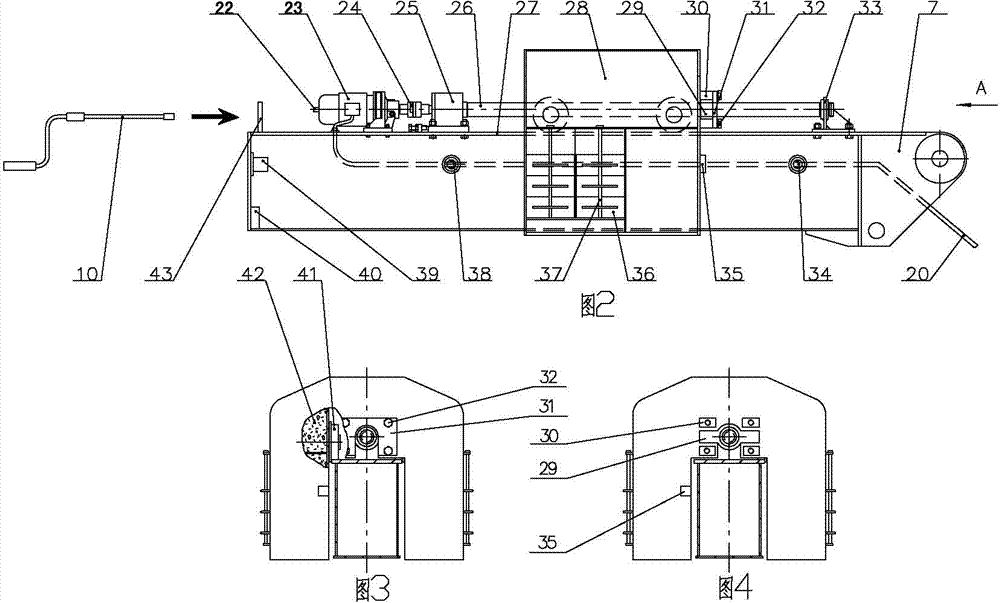

[0105] Embodiment 2, as attached figure 1 , 2 , 3, and 4, the intelligent pumping unit includes a main motor 15, a reducer 8, a crank 9, a connecting rod 6, a beam 3, a balance boom 7, a support 5, a donkey head 2, a base 12, and a braking device 13 , rope hanging device 1 and stroke process measuring device; main motor 15, speed reducer 8, braking device 13 and support 5 are fixedly installed on base 12, and the beam 3 that can swing up and down is hinged on the beam support 4 in the middle On the top of the bracket 5, a crank 9 is installed on the power output shaft of the reducer 8, the lower end of the connecting rod 6 is hinged with the crank 9, the upper end of the connecting rod 6 is hinged on the left part of the beam 3, and the right end of the beam 3 A donkey head 2 is fixedly installed, a rope suspension device 1 is installed on the donkey head 2, a balance boom 7 is fixedly installed on the left end of the beam 3, and a mobile counterweight box 28 and a movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com