A stabilizing screw drilling tool for extended reach directional wells

A technology for screw drilling tools and directional wells, which is applied in directional drilling, drill pipes, drill pipes, etc., can solve the problems of reduced drilling efficiency, insufficient tilt stabilization effect, and high sliding drilling ratio, so as to improve drilling efficiency and increase composite The effect of drilling time and reducing the number of orientations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

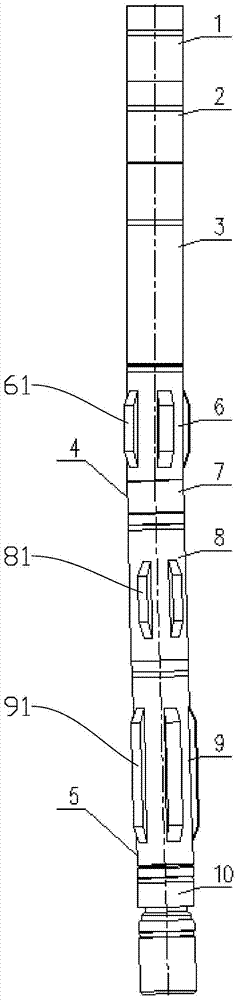

[0020] Such as figure 1 As shown, a stabilizing screw drilling tool for extended-reach directional wells includes a bypass valve assembly 1 , an anti-drop assembly 2 , a motor assembly 3 , a cardan shaft assembly 4 , and a transmission shaft assembly 5 .

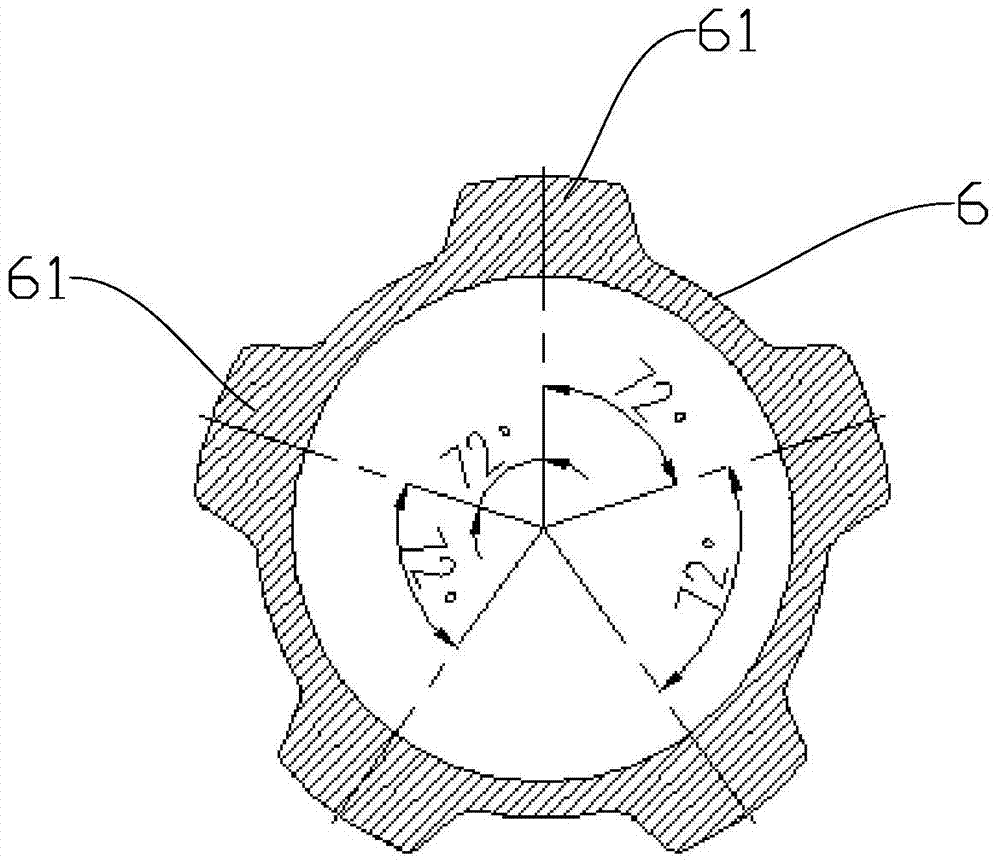

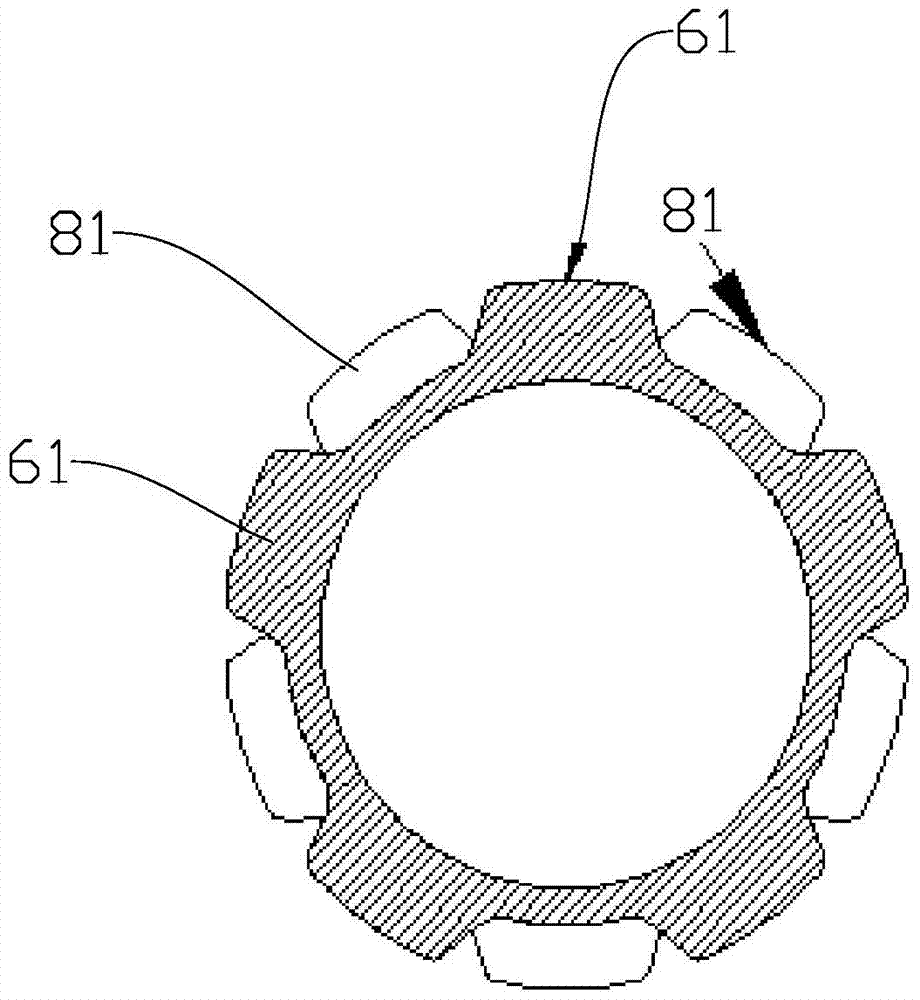

[0021] The cardan shaft assembly 4 includes a segmented cardan shaft housing; the cardan shaft housing includes three centering shells that are screwed in turn, and the direction from top to bottom is the upper centering shell 6, the middle Righting housing 7 and lower righting housing 8 .

[0022] The transmission shaft assembly 5 includes a transmission shaft housing, and the transmission shaft housing includes an upper bearing housing 9 and a lower bearing housing 10 .

[0023] The upper end of the upper bearing shell 9 is screwed to the lower end of the lower centering shell 8 ; the upper end of the lower bearing shell 10 is screwed to the bottom of the upper bearing shell 9 .

[0024] The axis of the middle centering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com