Mortise lock cylinder with variable length side pin and curved slot pick

A technology of curved groove and mortise locks, applied in the field of tumbler locks, can solve the problems of high production cost, poor anti-theft unlocking performance, and limited height, etc., achieve simple production process and structure, good anti-theft unlocking performance, and increase the difficulty of unlocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

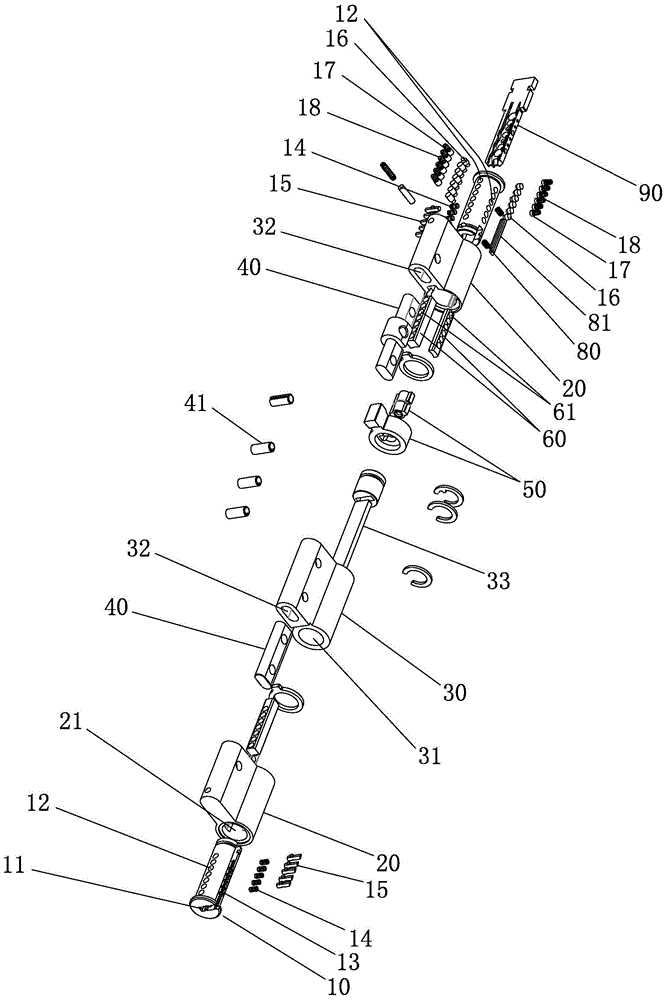

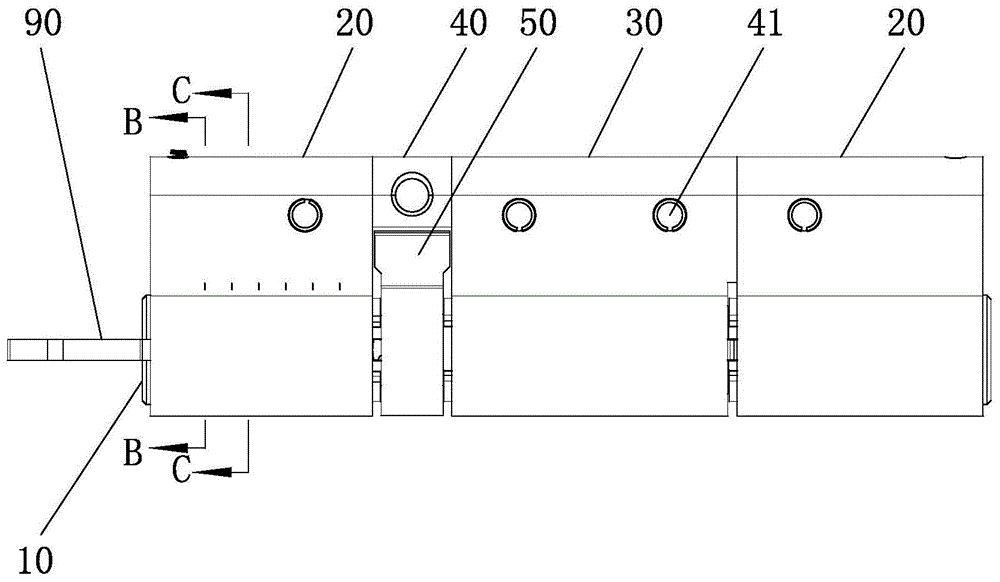

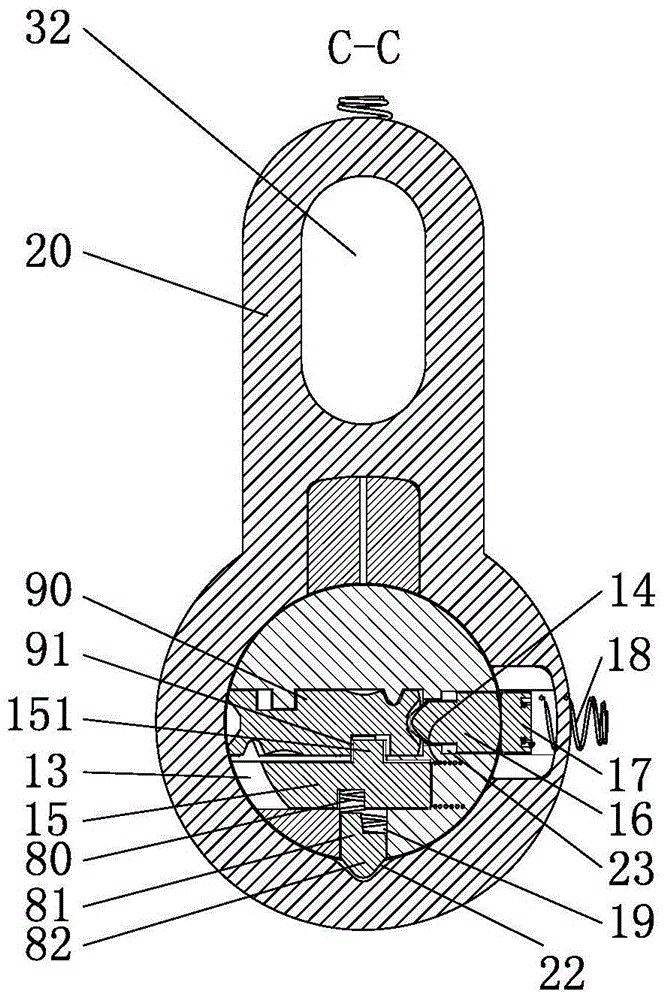

[0026] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 9 :

[0027] A mortise lock head with variable-length side pins and curved grooves for unlocking, including a lock body, a pin in the lock body, and a pin spring. The lock body 20 includes an inner lock body and an outer lock body, and the inner and outer lock bodies are arranged in sequence. A lock body connecting block 30 and an unlocking paddle 50 driven and rotated by a key 90 are provided, the lock body connecting block 30 is fixedly connected with the inner and outer lock bodies, and the lock core 10 is arranged in the axial lock hole 21 of the inner and outer lock body, and the lock core 10 Between the paddle 50 and the unlocking paddle 50, a connecting piece 33 driven by the key 90 to move axially is provided, and a groove 22, 23 which is axially provided on the upper wall of the lock hole 21 of the inner and outer loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com