Reciprocating bale plucker

A technology of reciprocating plucking machine and frame, which is applied in the direction of bag opening machine and hand bag opening, etc., which can solve the problems of troublesome operation and inability to perform automatic take-off and landing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Combine below Attached picture The preferred embodiments of the present invention are described in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

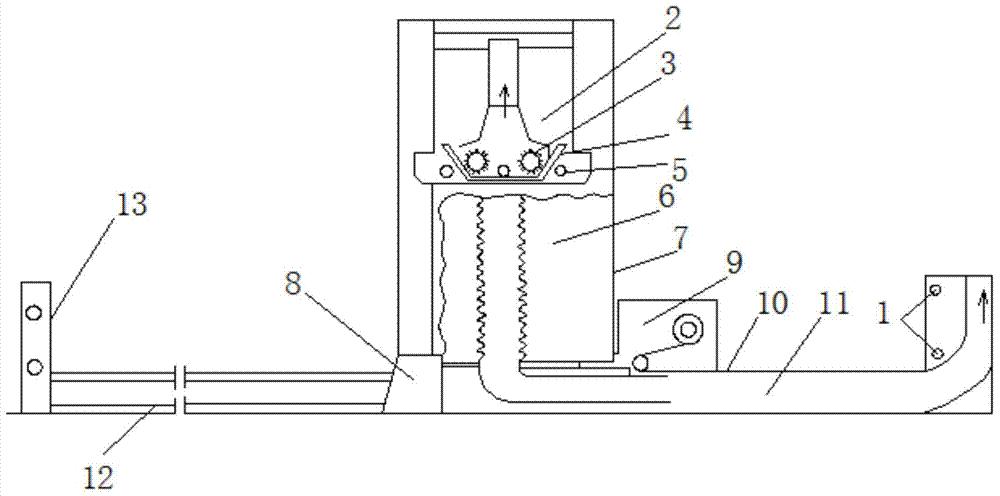

[0011] refer to figure 1 , the present embodiment adopts the following technical solutions: A reciprocating plucking machine , comprising a frame, a cotton pressing roller 5, a turret 7, a cotton catching trolley 8, a winding device 9 and a cotton delivery path 11, the two ends of the frame are provided with electrical control cabinets 13, and the frame is provided with a track 12. The frame is connected with a cotton picking trolley 8 through rails 12, a turret 7 is arranged on the frame, and a lifting mechanism is arranged on the top of the turret 7, and the inside of the turret 7 is connected by a lifting mechanism Cotton grabbing head 2 is provided, beater 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com